Foamed asphalt generation spraying system

A foamed asphalt and spraying system technology, which is applied to roads, road repair, roads, etc., can solve the problems of poor mixing effect of asphalt materials, and achieve the effects of improving construction quality, low price, and preventing outlet blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

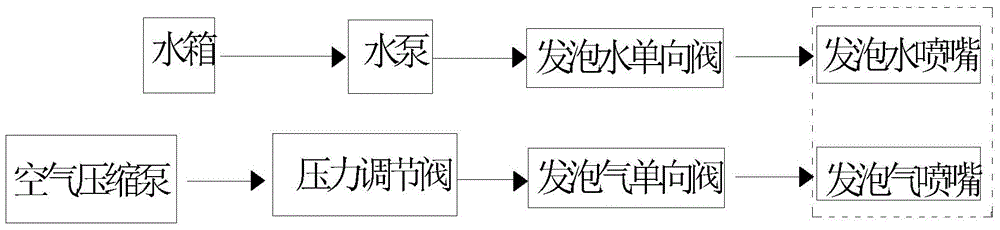

[0020] The principle of the invention: the hot asphalt and water are accurately measured, the compressed air is kept at normal pressure, and the three media are mixed in the foaming chamber; the water is vaporized instantly after being heated by the hot asphalt, and the body expands rapidly to form a large amount of asphalt foam. Under the blowing action of the blower, it is sprayed out from the outlet of the foamed asphalt.

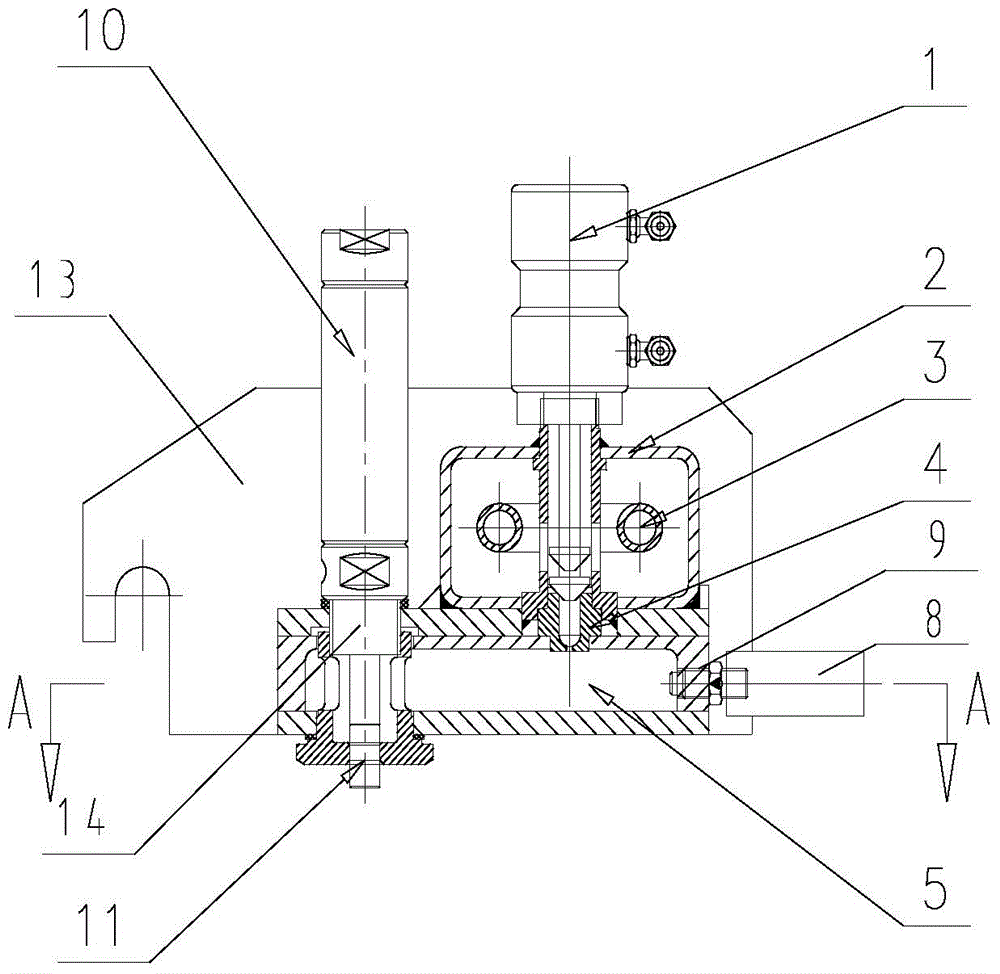

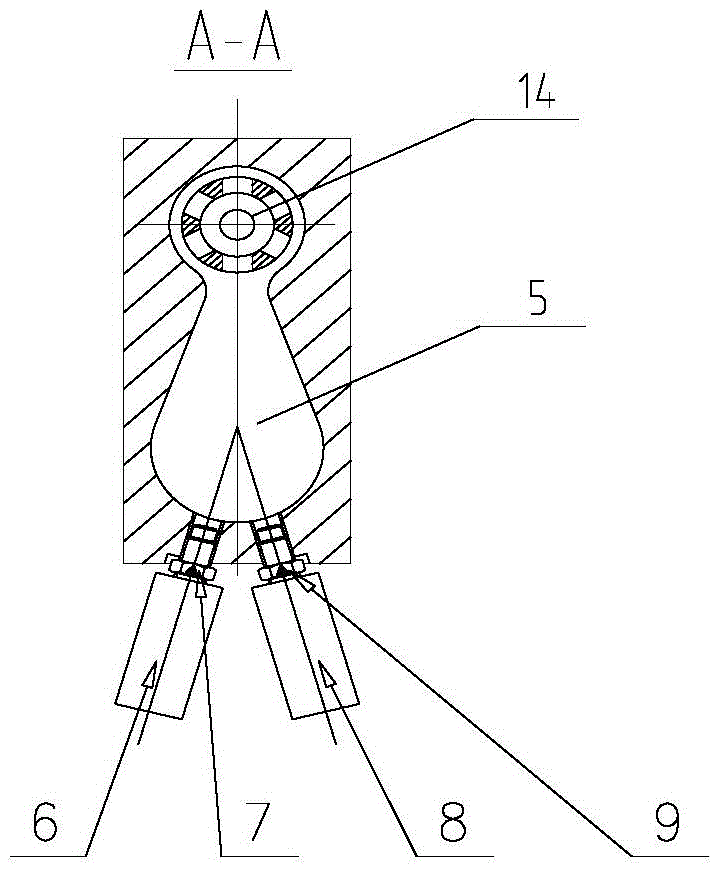

[0021] see Figure 1 to Figure 3 , a foamed asphalt generation spraying system, comprising a hot asphalt spraying chamber 2, a foaming unit, a control unit, a heating unit, a temperature sensor 12 arranged in the hot asphalt spraying chamber 2; the hot asphalt spraying chamber 2 is a cavity, and The asphalt conveying system is connected; the foaming unit includes asphalt foaming chamber 5, hot asphalt spraying control cylinder 1, asphalt nozzle 4, foamed asphalt spraying control cylinder 10, foamed asphalt outlet 11, foamed water conveying pipeline, foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com