High-speed vibration reduction and noise reduction environmental protection rail fixing system and its installation method

A technology of vibration reduction, noise reduction, and fixing system, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of damage to the rail fittings and track foundation, shortening the service life of the overall rail, and the lateral displacement cannot be released. Achieve vibration reduction and noise reduction, and solve the effect of rail gnawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The application will be further explained below in conjunction with the accompanying drawings.

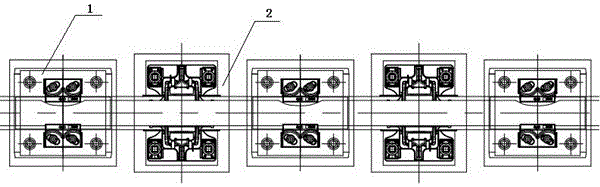

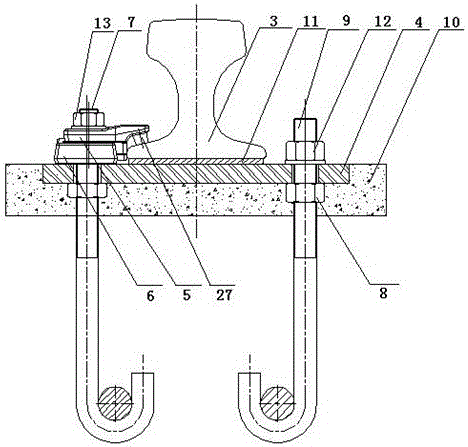

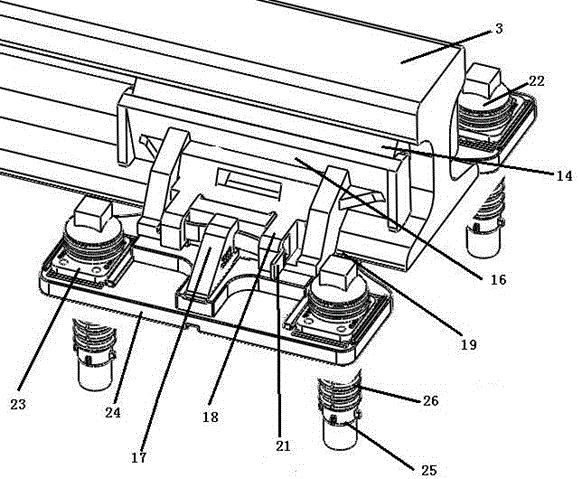

[0025] Such as figure 1 As shown, it is a schematic structural diagram of the compound installation of track-welding fastener system 1 and vibration-absorbing fastener system 2 on a section of rail 3, and a single track-welding fastener system and a single vibration-damping fastener system are alternately installed on the rail on the way. This composite installation method provides sufficient vertical support for the track through the rail bottom rubber plate of the vibration-absorbing fastener system; through the large contact area of the rubber stopper and the characteristics of the rubber itself to absorb elasticity and vibration, the wheel The instantaneous lateral force generated after the edge hits the rail instantly can be effectively absorbed by the rubber and quickly restore the track to the installation gauge. Due to the product characteristics of the welded ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com