Korean cashmere machine

A technology of hanrong machine and rubber shaft, which is applied in textile and papermaking, fiber raw material processing, paper and other directions, can solve the problems of low adjustment efficiency, high production cost, increase production cost, etc., to reduce production cost, ensure quality and effect, the effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

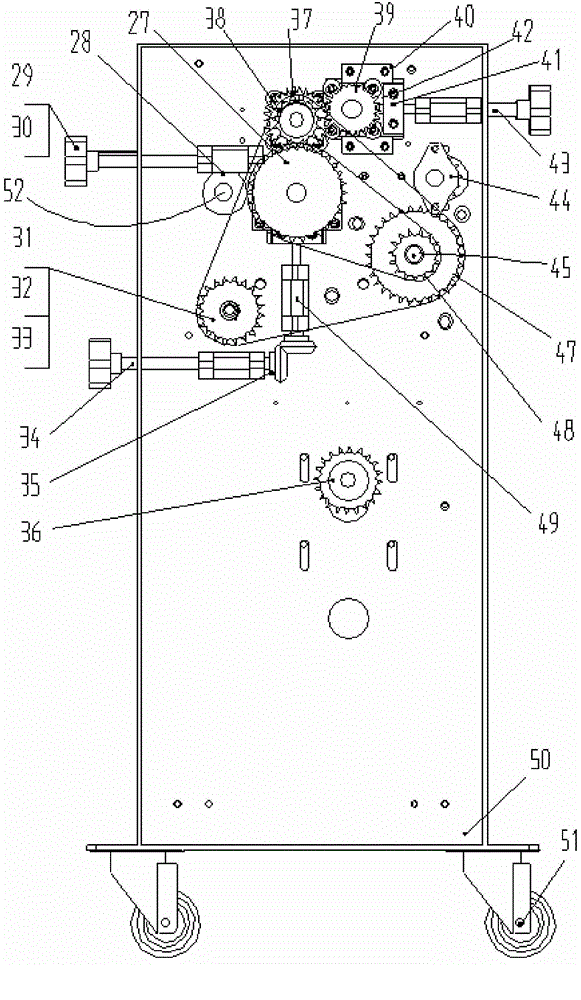

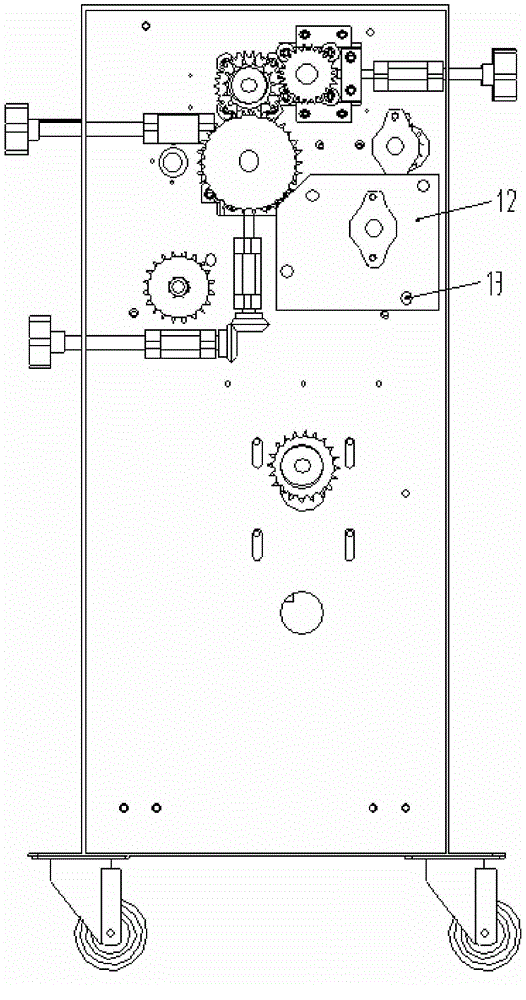

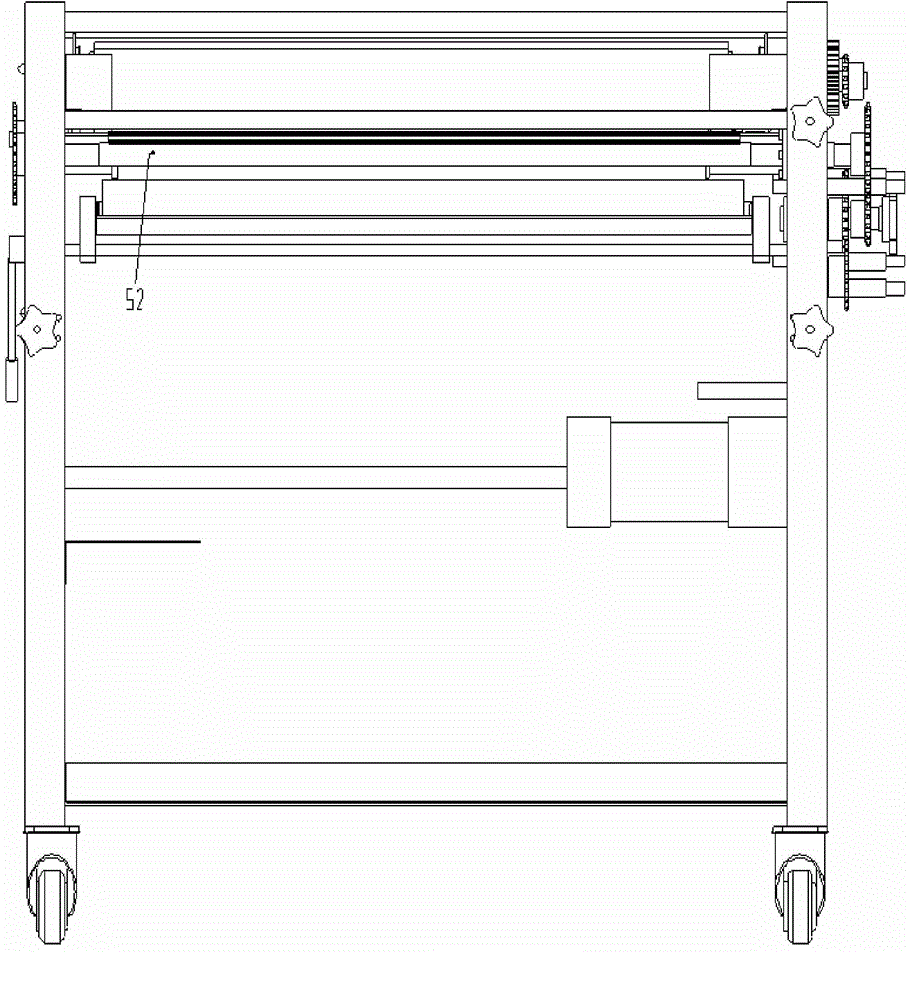

[0035] The serial numbers in the figure are: paper transmission shaft sprocket 1, lower rubber shaft sprocket 1, water pan adjustment ratchet 3, water pan adjustment sleeve 4, water pan adjustment handle 5, left side plate 6, optical axis bearing seat 7, Squeegee bushing 8, lower rubber shaft bearing plate 9, ratchet of water pan adjustment frame 10, support rod 1 of water pan adjustment frame 11, bridge plate 12, bridge plate support bar 13, glue box on the right side 14, bottom Rubber shaft 15, motor protection box 16, motor 17, reducer 18, optical axis 19, left glue box 20, paper transfer shaft 21, water pan 22, water pan bracket 23, water pan adjustment frame swing frame 24, Water pan adjustment frame support rod 225, rehydration pump bearing plate 26, lower rubber shaft sprocket 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com