Manufacturing method of titanium focus ring

A technology of focusing ring and manufacturing method, which is applied in the field of semiconductor technology, can solve problems such as quality problems of titanium slabs, and achieve the effects of meeting mechanical performance requirements, uniform thickness, and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

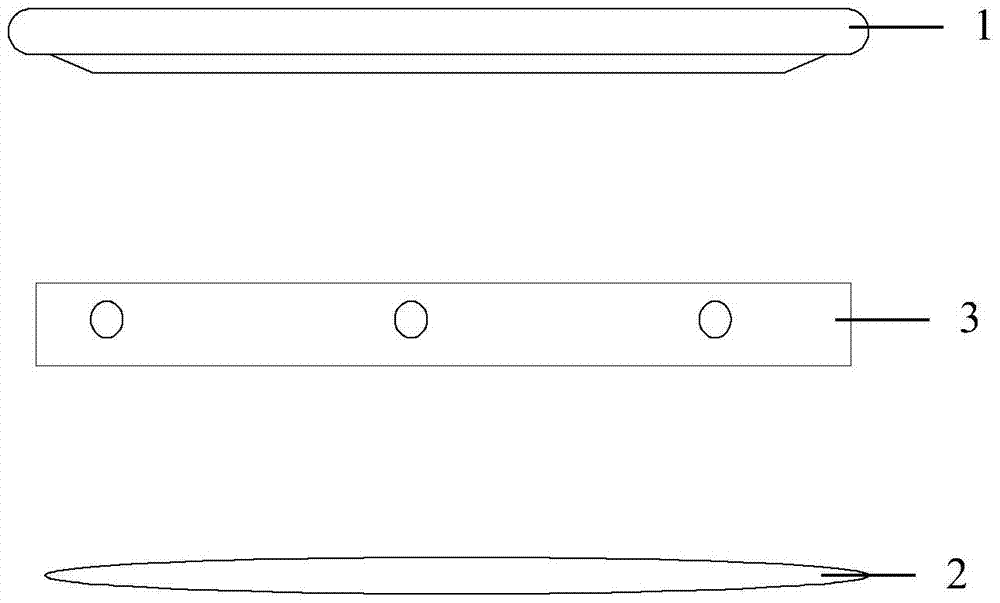

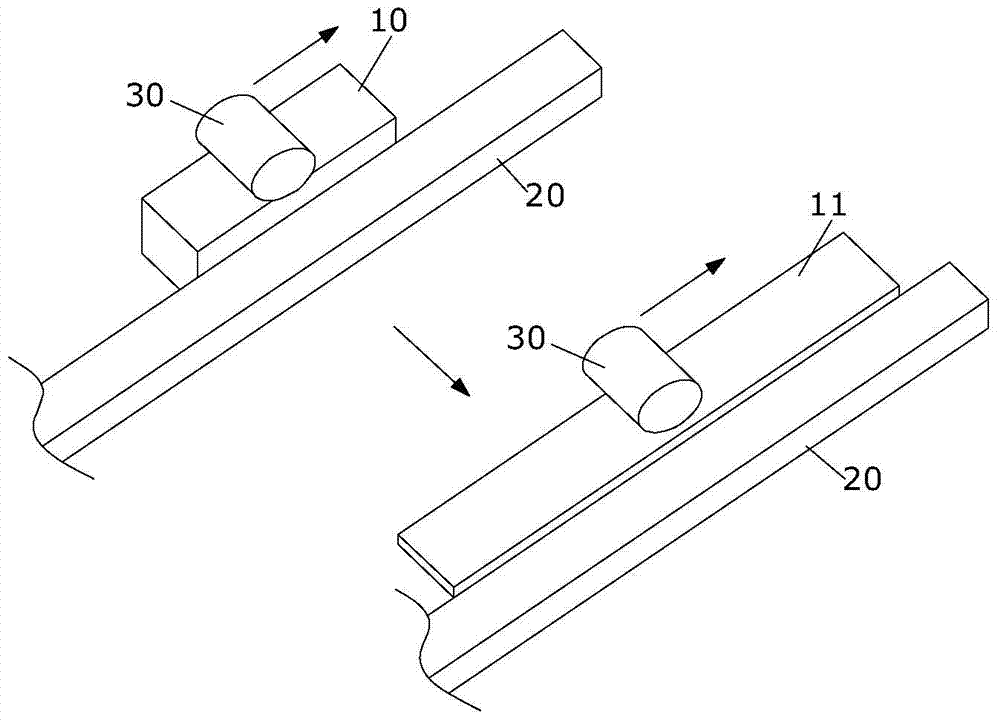

[0039] In the titanium focusing ring manufactured by the existing titanium focusing ring manufacturing method, the size of each part of the titanium focusing ring is not uniform, and it is prone to deformation during use, resulting in the formation of a titanium metal thin film layer when the titanium focusing ring is used for sputtering Poor uniformity.

[0040] To this end, the present invention provides a new method for manufacturing a titanium focusing ring. The titanium bar formed during the manufacturing process is flattened, and the titanium bar or titanium slab during the manufacturing process is heat treated, so as to make the surface of the titanium bar Flat, so as to ensure the uniform thickness of the titanium focus ring formed, and eliminate the internal stress of the titanium bar or titanium slab, and at the same time increase the crystal grains in the titanium bar or the titanium slab, so as to meet the requirements for making the titanium focus ring. The mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com