A production method of high-toughness 65mn spring steel with uniform cleaning rod performance

A production method and high-toughness technology, applied in the field of spring steel, can solve problems such as fluctuations in tensile strength and poor uniformity of cleaning rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

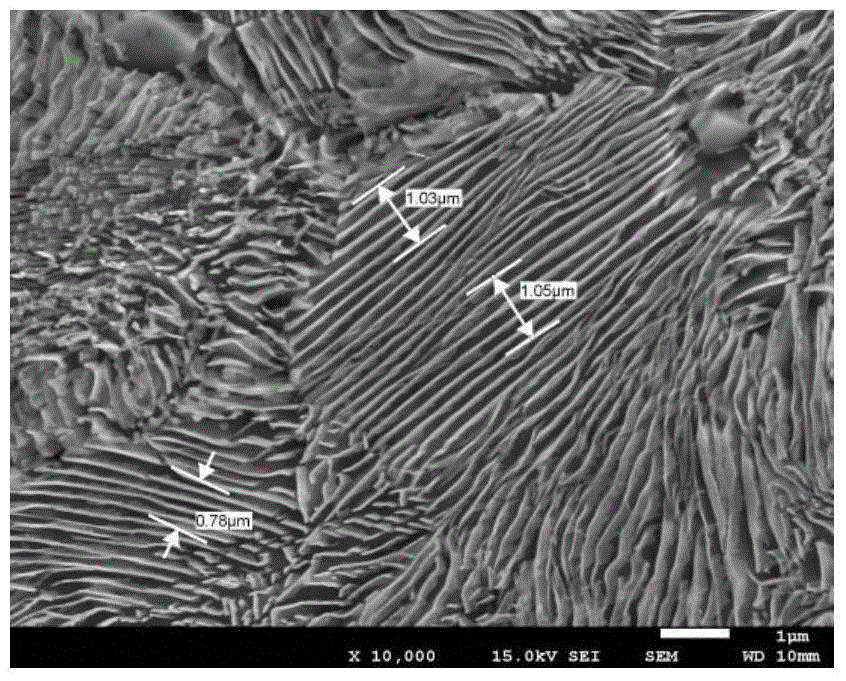

Image

Examples

Embodiment 1

[0024] The billets produced by converter smelting and LF furnace refining and continuous casting are then rolled into hot-rolled wire rods through steps such as heating in a heating furnace, rolling, and controlled cooling. In the rolling process, the rolling start temperature is 1025°C, and the four passes of rough rolling adopt tension-free rolling with head off, and the temperature at the entrance of the rolling mill after head off is 900°C. After the pre-finish rolling and before the finish rolling, the water tank is alternately cooled by water cooling-recovery-water cooling-recovery, and the cooling rate is 50°C / s; the surface of the billet before the finish rolling is bright without obvious black spots. The temperature at the entrance of finish rolling is 845°C. After finish rolling and before silk spinning, five stages of water cooling-recovery control are adopted, and the cooling rate is 100°C / s. In the cooling process, the silk spinning temperature is 830°C. During th...

Embodiment 2

[0031] The billets produced by converter smelting and LF furnace refining and continuous casting are then rolled into hot-rolled wire rods through steps such as heating in a heating furnace, rolling, and controlled cooling. In the rolling process, the rolling start temperature is 1005°C, and the four passes of rough rolling are head-off tension-free rolling, and the temperature at the entrance of the rolling mill after head-off is 890°C. After the pre-finish rolling and before the finish rolling, the water tank is alternately cooled by water cooling-recovery-water cooling-recovery, and the cooling rate is 41°C / s; the surface of the billet before the finish rolling is bright without obvious black spots. The temperature at the entrance of finish rolling is 840°C. After finish rolling and before spinning, five stages of water cooling-recovery control are adopted, and the cooling rate is 145°C / s. In the cooling process, the silk spinning temperature is 830°C. During the cooling pr...

Embodiment 3

[0033] The billets produced by converter smelting and LF furnace refining and continuous casting are then rolled into hot-rolled wire rods through steps such as heating in a heating furnace, rolling, and controlled cooling. In the rolling process, the rolling start temperature is 1020°C, and the four passes of rough rolling adopt tension-free rolling with head off, and the temperature at the entrance of the rolling mill after head off is 880°C. After the pre-finish rolling and before the finish rolling, the water tank is alternately cooled by water cooling-recovery-water cooling-recovery, and the cooling rate is 30°C / s; the surface of the billet before the finish rolling is bright without obvious black spots. The entrance temperature of finish rolling is 830°C. After finish rolling and before silk spinning, five-stage water cooling-recovery control is adopted, and the cooling rate is 100°C / s. In the cooling process, the silk spinning temperature is 850°C. During the cooling pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com