Ultrahigh-strength aluminum alloy refiner, and preparation and addition method thereof

A technology of refiner and aluminum alloy, which is applied in the field of materials, can solve problems such as unsatisfactory effects, and achieve the effects of significant refinement and purification effects, increased strength, and simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

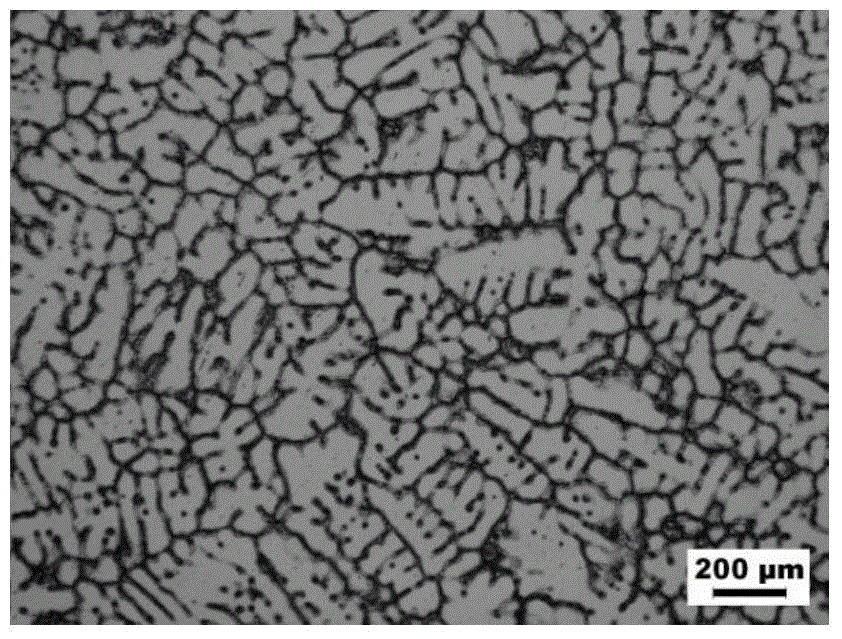

Image

Examples

Embodiment 1

[0023] Put high-purity aluminum into a graphite crucible, then place the graphite crucible in a resistance furnace, heat it to 780°C, melt the pure aluminum ingot, and add Al-RE respectively according to the nominal composition of Al-Zn-Mg-Cu alloy For master alloy and Al-Cu master alloy, add pure Mg ingot and Zn ingot after melting and stir evenly, then add appropriate amount of Be, heat up to 1000°C to prepare liquid refiner.

[0024] When the liquid refiner flows out of the crucible with the conduit, 1.0MPa nitrogen gas is added into the ring to atomize it to make a powder refiner, so that the content of each component meets 2.5wt% Cu, 1.5wt% Mg, 5wt% Zn, 0.4wt%RE, 0.2wt%Be, the balance is the mass percentage of Al. In order to prevent the oxidation of the refiner, the atomization tank is evacuated first, and then filled with nitrogen.

Embodiment 2

[0026] Put high-purity aluminum into a graphite crucible, then place the graphite crucible in a resistance furnace, heat it to 780°C, melt the pure aluminum ingot, and add Al-RE respectively according to the nominal composition of Al-Zn-Mg-Cu alloy For master alloy and Al-Cu master alloy, add pure Mg ingot and Zn ingot after melting and stir evenly, then add appropriate amount of Be, heat up to 950~1000°C to prepare liquid refiner.

[0027] When the liquid refiner flows out of the crucible with the conduit, add 1.0MPa nitrogen in a ring to atomize it to make a powder refiner, so that the content of each component meets 1.0wt% Cu, 3.0wt% Mg, 4.5wt %Zn, 0.5wt%RE, 0.3wt%Be, and the balance is the mass percentage of Al. In order to prevent the oxidation of the refiner, the atomization tank is evacuated first, and then filled with nitrogen.

Embodiment 3

[0029] Put high-purity aluminum into a graphite crucible, then place the graphite crucible in a resistance furnace, heat it to 780°C, melt the pure aluminum ingot, and add Al-RE respectively according to the nominal composition of Al-Zn-Mg-Cu alloy For master alloy and Al-Cu master alloy, add pure Mg ingot and Zn ingot after melting and stir evenly, then add appropriate amount of Be, heat up to 980°C to prepare liquid refiner.

[0030] When the liquid refiner flows out of the crucible with the conduit, add 1.0MPa nitrogen in a ring to atomize it to make a powder refiner, so that the content of each component meets 2.0wt% Cu, 2.0wt% Mg, 6.5wt %Zn, 0.5wt%RE, 0.4wt%Be, and the balance is the mass percentage of Al. In order to prevent the oxidation of the refiner, the atomization tank is evacuated first, and then filled with nitrogen.

[0031] The composition of the Al-Zn-Cu-Mg series super-strength aluminum alloy is similar to that of the refining agent used. After the alloy is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com