Hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon

A technology for low-carbon olefins and light aromatics, applied in the field of catalytic conversion of hydrocarbons, which can solve the problems of increasing catalytic cracking propylene, which is limited and does not involve improving selectivity, and achieves the effect of suppressing hydrogen transfer reaction and high process flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The cracking catalyst used in this embodiment is: based on the total weight of the cracking catalyst, the cracking catalyst used contains 10% by weight of beta zeolite, 20% by weight of ZSM-5 zeolite (the ratio of silicon to aluminum is 40), 45% by weight of Kaolin and 25% by weight of alumina binder, wherein the beta zeolite contains 1% by weight of iron and 1.5% by weight of phosphorus in terms of elements. The cracking catalyst is aged for 10 hours at 800°C and 100% water vapor atmosphere, and the catalyst loading in the device (system catalyst storage) is 60 kg.

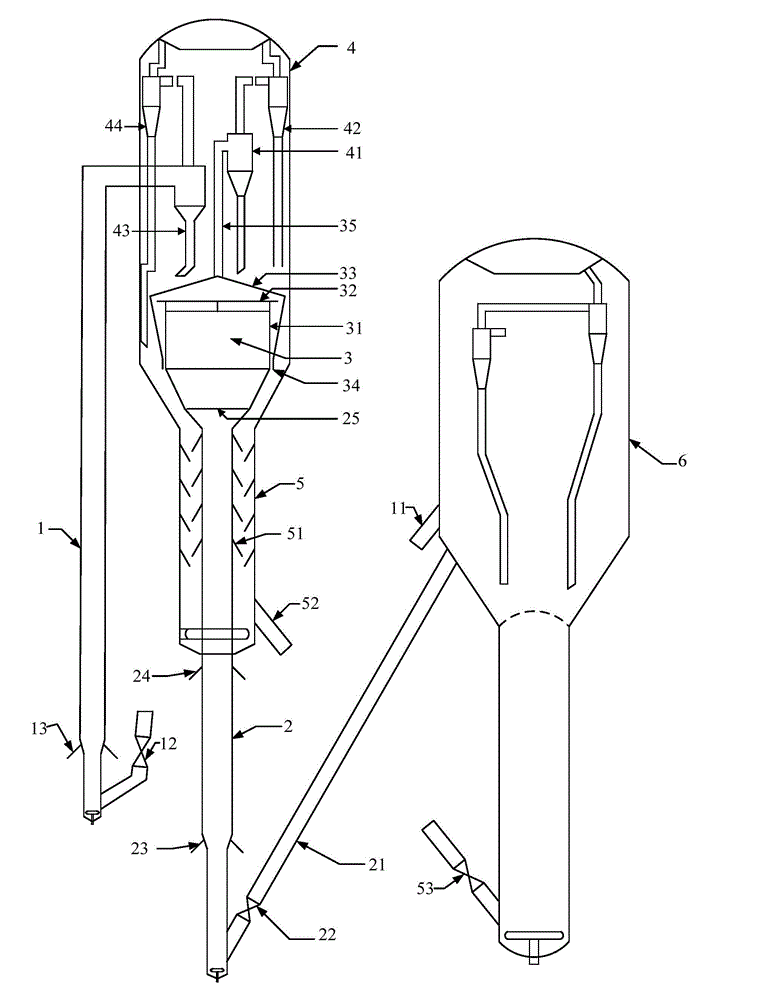

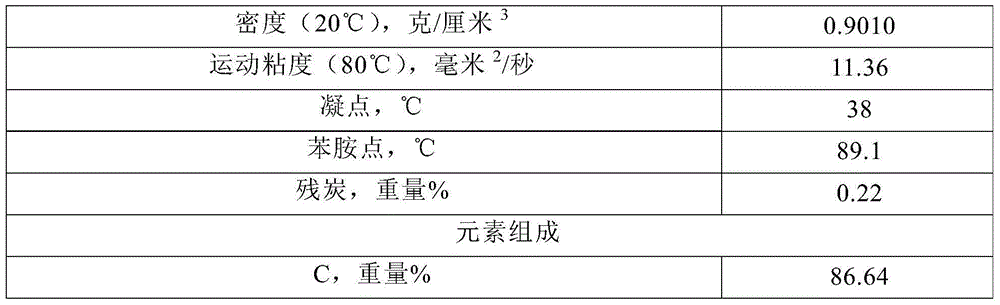

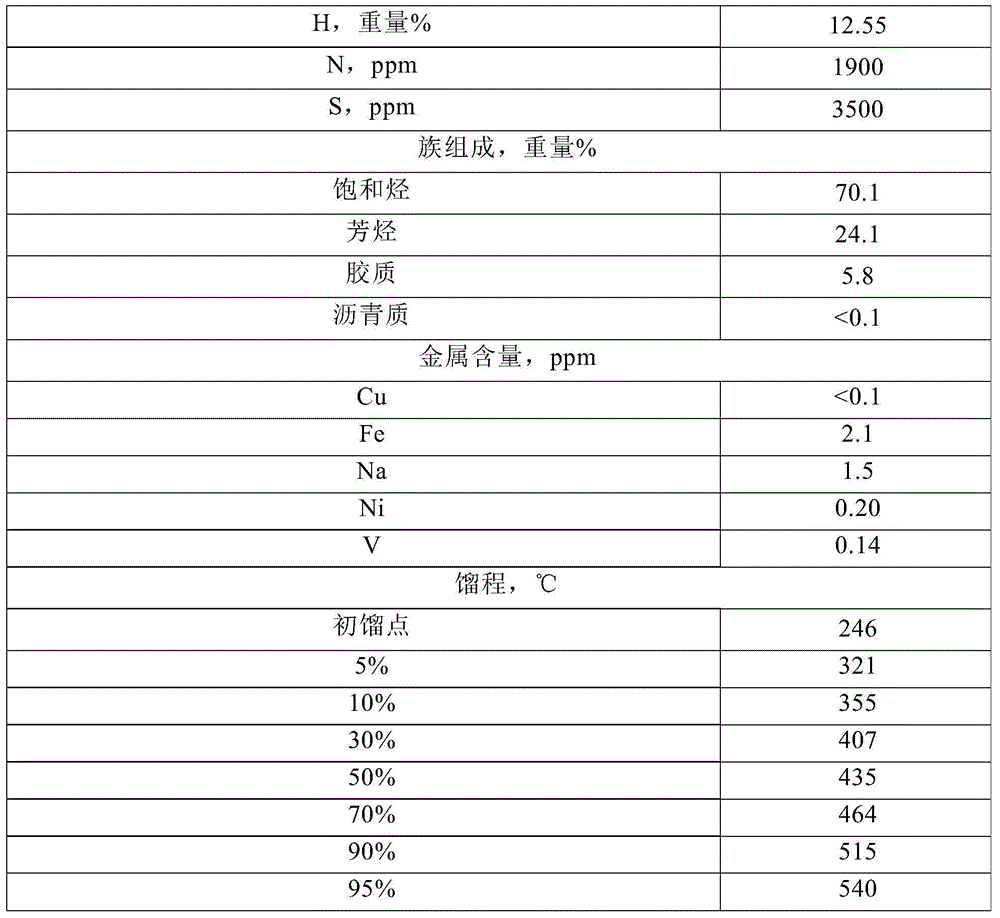

[0093] The heavy hydrocarbon oil raw material (its properties are shown in Table 1) is introduced into the riser reactor 1, and after being contacted with the hot catalyst from the regenerator 6, the reaction oil gas is separated from the catalyst, and the reaction oil gas leaves the reactor and is introduced into the fractionation device, separated The obtained coke catalyst is introduced into the strippe...

Embodiment 2

[0095] The process flow and the cracking catalyst used in this example are the same as in Example 1, except that light gasoline (see Table 2 for properties) is used at a reaction temperature of 40°C, a reaction pressure of 0.5MPa, and a molar ratio of hydrogen to olefins of 4:1. After selective hydrogenation reaction on the hydrogenation catalyst (purchased from Sinopec Changling Catalyst Branch, the brand is RDD-1), dienes and alkynes are converted into monoolefins and introduced into riser reactor 2, and the remaining reaction conditions and The reaction results are shown in Table 4.

Embodiment 3

[0101] The flow process of this embodiment is the same as that of Example 1. The difference is that the cracking catalyst used is: based on the total weight of the cracking catalyst, the cracking catalyst used contains 15% by weight of zeolite beta, 15% by weight of ZSM-5 zeolite (silicon Aluminum ratio is 40), 45% by weight of kaolin and 25% by weight of alumina binder, wherein, zeolite beta contains 1% by weight of iron and 1.5% by weight of phosphorus in terms of elements; and, reaction conditions and reaction results See Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com