Organic electroluminescent material, preparation method of organic electroluminescent material and organic electroluminescent device

An electroluminescence, electromechanical technology, applied in the field of phosphorescent materials, can solve the problems of blue shift of luminescence wavelength, HOMO energy level drop, luminescence color purity of blue-light phosphorescence materials, efficiency attenuation bottleneck of luminous efficiency devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

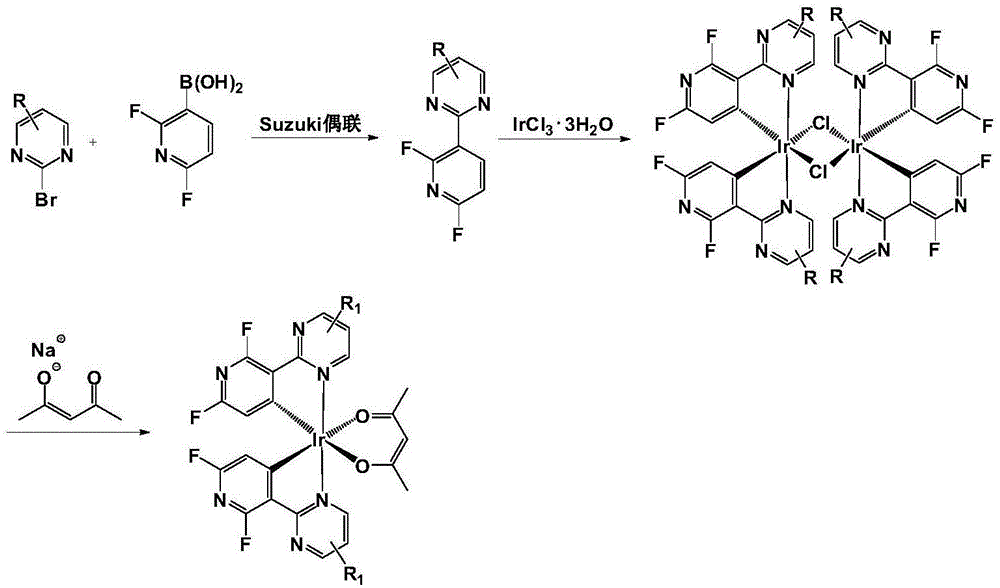

[0047] The preparation process of the organic electroluminescent material (P) of the present invention is roughly divided into the following steps:

[0048] (1) Synthesize compound C from compound E and compound F through Suzuki coupling reaction; wherein, compound F is 2,6-

[0049] Difluoropyridine-3-boronic acid, the structural formulas of compound E and compound C are as follows:

[0050] Compound E is Compound C is Among them, R 1 is a hydrogen atom, C 1~20 straight chain alkyl, C 1~20 Branched chain alkyl, C 1~20 straight chain alkoxy or C 1~20 branched chain alkoxy.

[0051] (2) Reaction of compound C prepared in step (1) with compound D to generate a chlorine-bridged dimer, namely compound A. Wherein, compound D is trihydrate iridium trichloride IrCl 3 ·3H 2 O. The structural formula of compound A is as follows:

[0052]

[0053] (3) Compound A prepared in step (2) is used as a ring metal ligand, and compound B is used as an auxiliary ligand source to ...

Embodiment 1

[0058] The organic electroluminescent material (P) disclosed in this example is the complex bis(2-(2′,6′-difluoropyridin-3′-yl)pyrimidine-N,C 4′ ) (acetylacetonate) iridium, its structural formula is as follows:

[0059]

[0060] It is prepared by the following steps:

[0061] (1) Synthesis of 2-(2′,6′-difluoropyridin-3′-yl)pyrimidine

[0062] The synthetic reaction formula of 2-(2',6'-difluoropyridin-3'-yl)pyrimidine is as follows:

[0063]

[0064] The specific steps are: under nitrogen atmosphere, 1.59g (10mmol) 2-bromopyrimidine, 1.91g (12mmol) 2,6-difluoropyridine-3-boronic acid and 0.58g (0.5mmol) tetrakis (triphenylphosphine) palladium Dissolve in 40ml of toluene, then add dropwise 20ml of a solution containing 2.76g (20mmol) of potassium carbonate to the reaction system. Heat to 100°C and stir the reaction for 8h. After the reaction solution was cooled to room temperature, it was extracted with dichloromethane, separated, washed with water until neutral, and ...

Embodiment 2

[0080]The organic electroluminescent material disclosed in this example is the complex bis(2-(2′,6′-difluoropyridin-3′-yl)-5-methylpyrimidine-N,C 4′ ) (acetylacetonate) iridium, its structural formula is as follows:

[0081]

[0082] It is prepared by the following steps:

[0083] (1) Synthesis of 2-(2′,6′-difluoropyridin-3′-yl)-5-methylpyrimidine

[0084] The reaction formula for the synthesis of 2-(2′,6′-difluoropyridin-3′-yl)-5-methylpyrimidine is as follows:

[0085]

[0086] The specific steps are: under nitrogen atmosphere, 1.73g (10mmol) 2-bromo-5-methylpyrimidine, 1.59g (10mmol) 2,6-difluoropyridine-3-boronic acid and 0.28g (0.4mmol) dichlorobis (Triphenylphosphine)palladium was dissolved in 50ml of DMF, and then 25ml of sodium carbonate solution containing 3.18g (30mmol) was added dropwise to the reaction system. Stir the reaction under heating to 90°C for 10 h. After the reaction solution was cooled to room temperature, it was extracted with dichloromethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com