Drag reducer for fracturing shale gas and preparation method of drag reducer

A technology of drag reducer and air pressure, which is applied in the field of drag reducer for shale gas fracturing fluid and its preparation, and can solve the problems of low drag reduction rate of drag reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

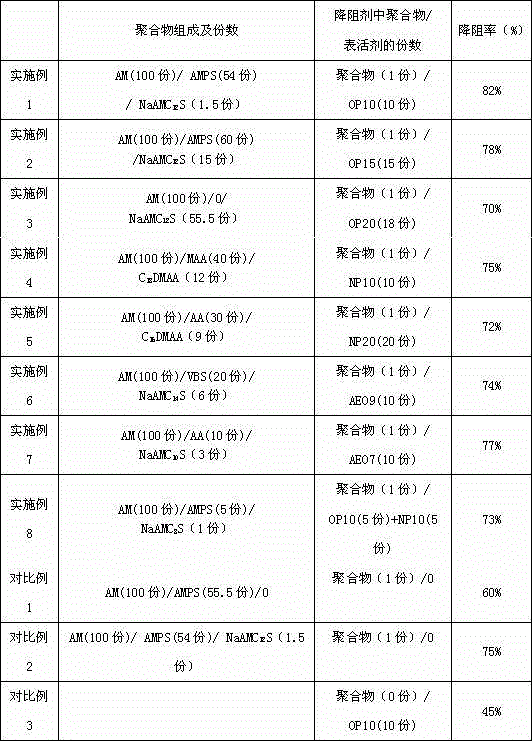

Examples

Embodiment 1

[0034] 1. Polymer synthesis

[0035] First add 650g deionized water to the polymerization kettle, add 100g acrylamide (AM), 54g 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 1.5g 2-acrylamidododecylsulfonic acid Sodium (NaAMC 12 S), stirred until it was completely dissolved, adjusted the pH value to 9 with NaOH, and started to feed high-purity nitrogen gas. After 30 minutes, the temperature in the kettle was lowered to 15°C, and then 15.5g of 0.1wt% sodium bisulfite aqueous solution and 0.1wt% Potassium persulfate aqueous solution 15.5g is used as initiator, seals after continuing nitrogen gas 30min. After 1 hour, the reaction temperature was gradually raised to 45°C. After 3 hours of reaction, a water-containing gel-like polymer product was obtained. After cutting the glue, it was blown and dried at 90°C for 1.5 hours, crushed and sieved with a pulverizer to obtain dry hydrophobic associative polymers.

[0036] 2. Preparation of drag reducer

[0037] In 10L of water, ...

Embodiment 2

[0045] 1. Polymer synthesis

[0046] First add 650g deionized water to the reaction kettle, add 100g acrylamide (AM), 60g 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 15g 2-acrylamido sodium dodecylsulfonate ( NaAMC 12 S), stirred until completely dissolved, adjusted the pH value to 9 with NaOH, and began to feed high-purity nitrogen gas, and after 30 minutes, the temperature in the kettle was lowered to 15°C, and then 17.5g of 0.1wt% sodium bisulfite aqueous solution was added successively And 17.5 g of aqueous potassium persulfate solution of 0.1wt% is used as initiator, and seals after continuing nitrogen gas 30min. After 1 hour, the reaction temperature was gradually increased to 45°C. After 3 hours of reaction, a gel-like polymer product was obtained. After cutting the gel, it was blown and dried at 90°C for 1.5 hours, crushed and sieved with a pulverizer to obtain a water-soluble hydrophobic association polymer things.

[0047] 2. Preparation of drag reducer

[...

Embodiment 3

[0053] 1. Polymer synthesis

[0054] First add 650g of deionized water to the reaction kettle, add 100g of acrylamide (AM), 55.5g of 2-acrylamido sodium dodecylsulfonate (NaAMC 12 S), stirred until completely dissolved, adjusted the pH value to 9 with NaOH, and began to pass high-purity nitrogen gas, and after 30 minutes, the temperature in the kettle was lowered to 15°C, and then 15.5g of 0.1wt% sodium bisulfite aqueous solution and 0.1wt% Potassium persulfate aqueous solution 15.5g is used as initiator, seals after continuing nitrogen gas 30min. After 1 hour, the reaction temperature was gradually raised to 45°C. After 3 hours of reaction, a gel-like polymer product was obtained. After cutting the gel, it was air-dried at 90°C for 1.5 hours, crushed and sieved with a pulverizer to obtain a hydrophobic association polymer.

[0055] 2. Preparation of drag reducer

[0056] In 10L of water, add 1g of water-soluble hydrophobic association polymer, 18g of OP20 and 100g of KCl, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com