A kind of preparation method of in-situ toughened polypropylene alloy

A polypropylene and polypropylene resin technology, which is applied in the field of in-situ toughened polypropylene alloy preparation, can solve problems such as poor interfacial compatibility, and achieve the effects of good interfacial compatibility, uniform dispersion of dispersed phase and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put 15g of polybutadiene and 200ml of cyclohexane into a 500ml three-necked bottle, and at 65°C, after the high vinyl polybutadiene is completely dissolved, slowly add 3.2g of formic acid and 0.6g of polyethylene glycol into the system, After the dropwise addition, react for 0.5 hours, slowly add 3.2g of hydrogen peroxide into the system dropwise within 20min, and continue to react for 2 hours at a constant temperature. After the reaction, pour out the product, and add absolute ethanol to precipitate the solid , settle for a period of time, filter with suction, wash the product solid several times with sodium bicarbonate solution and distilled water, put it in an oven at 60°C for 12 hours in vacuum, and obtain a white tough product.

Embodiment 2

[0030] Put 15g of polybutadiene and 200ml of cyclohexane into a 500ml three-necked bottle. At 65°C, after the high vinyl polybutadiene is completely dissolved, slowly add 1.8 formic acid and 0.3g of polyethylene glycol into the system, drop After the addition, react for 0.5 hours, slowly drop 1.8g of hydrogen peroxide into the system within 20min, continue to react at constant temperature for 2 hours, after the reaction, pour out the product, add absolute ethanol to precipitate the solid, After settling for a period of time, filter with suction, wash the product solid several times with sodium bicarbonate solution and distilled water, and put it into an oven for 12 hours at 60°C to vacuum dry to obtain a white tough product.

Embodiment 3-6

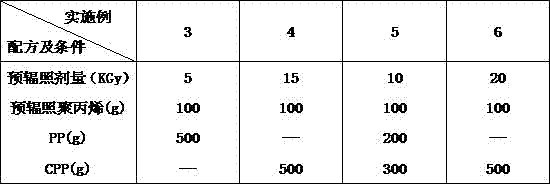

[0032] The electron accelerator was used to pre-irradiate the copolymerized polypropylene, and the irradiation dose was listed in Table 1 to prepare the pre-irradiated polypropylene with macromolecular peroxide.

[0033] Copolymerized polypropylene, ethylene-propylene random copolymer (CPP) or their blends are pre-irradiated to prepare pre-irradiated polypropylene with macromolecular peroxide. The reaction extrusion grafting temperature is 200° C., the screw speed is 80 rpm, and the material residence time is 3 minutes. The ratio of pre-irradiated polypropylene materials is shown in Table 1. The copolymer polypropylene used had a melt flow rate of 2.0 g / 10 min and the CPP used had a melt flow rate of 3.0 g / 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com