Method for producing paraxylene by using multistage suspension crystallization process

A p-xylene and suspension crystallization technology, applied in crystallization purification/separation, organic chemistry, etc., can solve the problems of unstable product quality and output, difficult crystal washing, high energy consumption, etc., and achieve consistent output, good technical effect, The effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention relates to a crystallization method for producing p-xylene by multistage suspension crystallization.

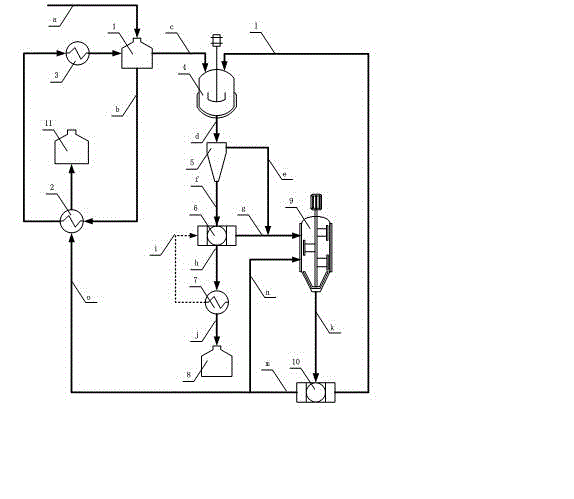

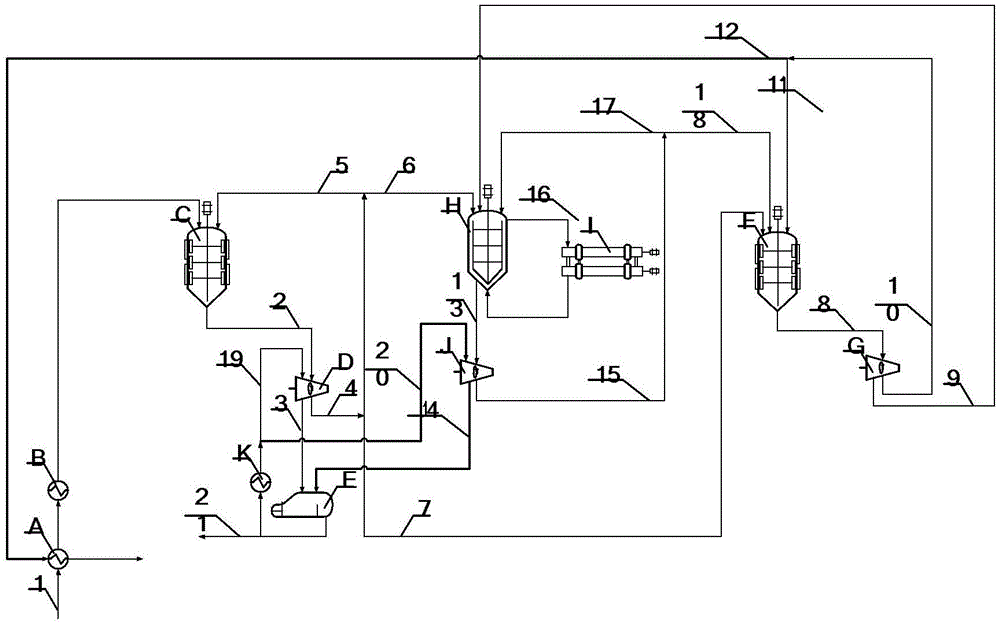

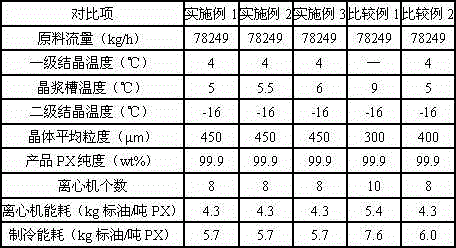

[0021] Such as figure 1 Said, mixed xylene raw material 1, the temperature is 50 ℃, the content of p-xylene is 94wt%, the flow rate is 78249kg / h, after being cooled to 20 ℃ by mother liquor heat exchanger A and precooler B, it enters primary crystallizer C The crystallization temperature is 4°C; the crystal slurry 2 in the primary crystallizer is separated by the solid-liquid separator D to obtain p-xylene crystals 3 and the primary crystallization mother liquor 4, and the p-xylene crystals 3 are separated in the solid-liquid separator D After being washed by the washing liquid 19, it enters the melting tank E, and the primary crystallization mother liquor 4 is divided into three shares, and the first-stage crystallization mother liquor 5 accounting for 80% by weight returns to the primary crystallizer C, and the second share accounts for 10% by weight T...

Embodiment 2

[0024] The invention relates to a crystallization method for producing p-xylene by multistage suspension crystallization.

[0025] According to the operating condition of embodiment 1, adopt as figure 1 In the crystallization method for producing p-xylene by multi-stage suspension crystallization, the operating temperature of the magma tank is 5.5°C.

[0026]

Embodiment 3

[0028] The invention relates to a crystallization method for producing p-xylene by multistage suspension crystallization.

[0029] According to the operating condition of embodiment 1, adopt as figure 1 In the crystallization method for producing p-xylene by multi-stage suspension crystallization, the operating temperature of the magma tank is 6°C.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com