Molasses fermentation liquor water-soluble fertilizer and preparation method thereof

A technology of molasses fermentation liquid and fertilizer, applied in liquid fertilizer, organic fertilizer, inorganic fertilizer and other directions, can solve the problems of affecting the quality of crops, destroying the physical and chemical properties of soil, endangering human health, etc., to achieve resource utilization and enhance economic value. , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

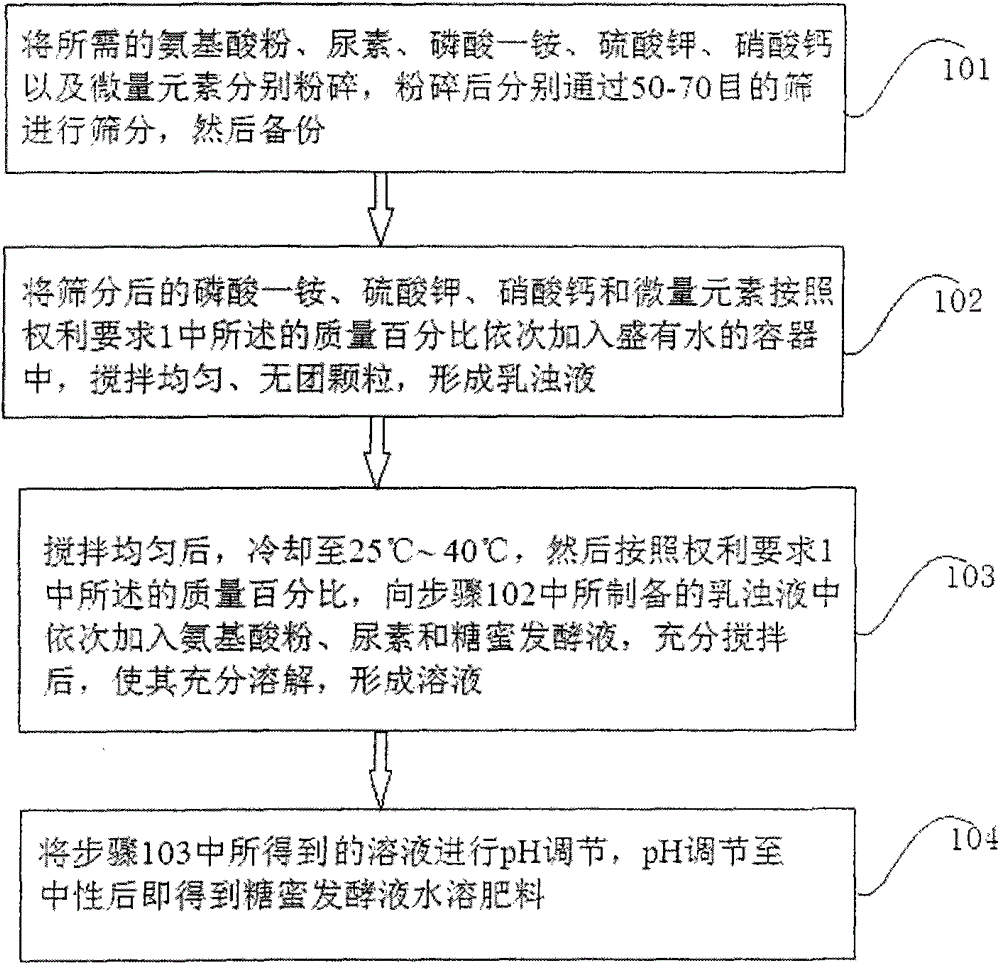

[0026] Such as figure 1 Shown, the embodiment of the present invention also provides a kind of preparation method of molasses fermented liquid water-soluble fertilizer, and this method comprises the following steps:

[0027] Step 101: Separately pulverize the required amino acid powder, urea, monoammonium phosphate, potassium sulfate, calcium nitrate and trace elements, sieve through 50-70 mesh sieves after pulverization, and then backup;

[0028] Step 102: add the sieved monoammonium phosphate, potassium sulfate, calcium nitrate and trace elements in sequence according to the mass percentages described in claim 1 into a container filled with water, and stir evenly without agglomerates to form an emulsion ;

[0029] Step 103: After stirring evenly, cool to 25°C-40°C, and then add amino acid powder, urea and molasses fermentation liquid to the emulsion prepared in step 102 in sequence according to the mass percentage described in claim 1, fully After stirring, it is fully dis...

specific Embodiment 1

[0036] Concrete embodiment 1: take the production of 1000 kilograms of molasses fermented liquid water-soluble fertilizer as example, concrete method is as follows:

[0037] Step 101: Mix 170 kg of amino acid powder, 50 kg of urea, 100 kg of monoammonium phosphate, 150 kg of potassium sulfate, 40 kg of calcium nitrate, 2.7 kg of zinc sulfate, 3.1 kg of manganese sulfate, 0.3 kg of boric acid, and 3.9 kg of ammonium molybdate Kilograms are crushed separately, and after crushing, they are sieved through a 60-mesh sieve, and then backed up;

[0038] Step 102: Add the sieved monoammonium phosphate, potassium sulfate, calcium nitrate and trace elements in sequence according to the mass percentages described in claim 1 into a container filled with 180 kg of water, and stir evenly without agglomerates to form emulsion;

[0039]Step 103: After stirring evenly, cool to 30°C, and then add amino acid powder, urea and 250 kg of molasses fermentation liquid to the emulsion prepared in ste...

specific Embodiment 2

[0041] Concrete embodiment 2: take the production of 1000 kilograms of molasses fermented liquid water-soluble fertilizer as example, concrete method is as follows:

[0042] Step 101: Add 150 kg of amino acid powder, 70 kg of urea, 130 kg of monoammonium phosphate, 200 kg of potassium sulfate, 28 kg of calcium nitrate, 0.6 kg of zinc sulfate, 1.0 kg of manganese sulfate, 0.05 kg of boric acid, and 0.35 kg of ammonium molybdate. Kilograms are crushed separately, and after crushing, they are sieved through a 60-mesh sieve, and then backed up;

[0043] Step 102: Add the sieved monoammonium phosphate, potassium sulfate, calcium nitrate and trace elements in sequence according to the mass percentages described in claim 1 into a container filled with 200 kg of water, and stir evenly without agglomerate particles to form emulsion;

[0044] Step 103: After stirring evenly, cool to 30°C, then add amino acid powder, urea and 220 kg of molasses fermentation liquid to the emulsion prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com