Modified high-alumina brick for cold ends of calcining zone and transitional zone of cement kiln and method for preparing high-alumina brick

A high-alumina brick and transition zone technology, applied in the field of refractory materials, can solve the problems of high SiC burning loss, high price, heat loss, etc., and achieve the effect of reducing production energy consumption and improving thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

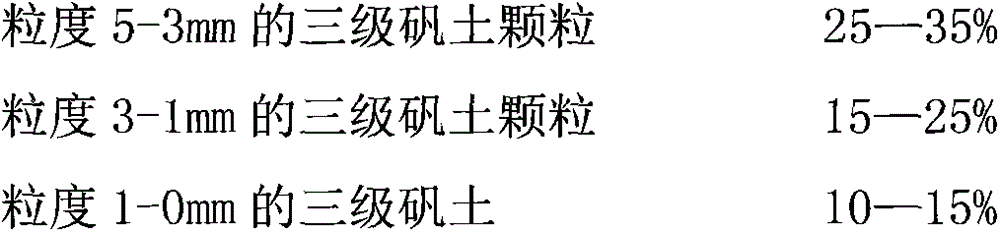

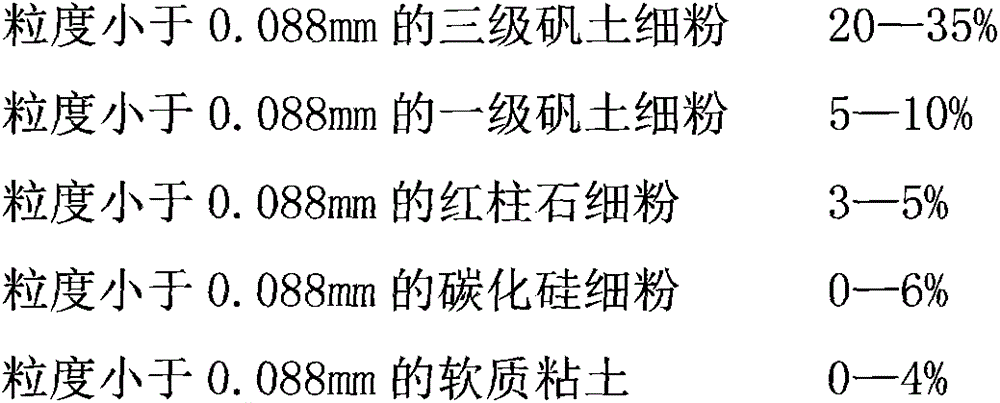

[0014] Modified high alumina bricks for the cold end of the decomposition zone and transition zone of cement kilns, in terms of weight percentage, include the following preparation materials:

[0015]

[0016] Add 5% of the total weight of the above raw materials phosphoric acid (specific gravity 1.4g / cm 3 ) As a binding agent.

[0017] The above-mentioned materials are mixed and milled according to the proportion. The granules are added first, then the fine powder is added, and finally the binder is added. After mixing and milling, the material is trapped for 4 hours, and then pressed into a drying kiln for drying. The drying temperature is 120°C and the drying time is 24 hours. Then it is sent to a high-temperature tunnel kiln with natural gas as fuel for calcination and heat preservation for 6 hours, and the sintering temperature is 1300℃. That is, the product has a thermal conductivity of 1.0W / (m·K).

Embodiment 2

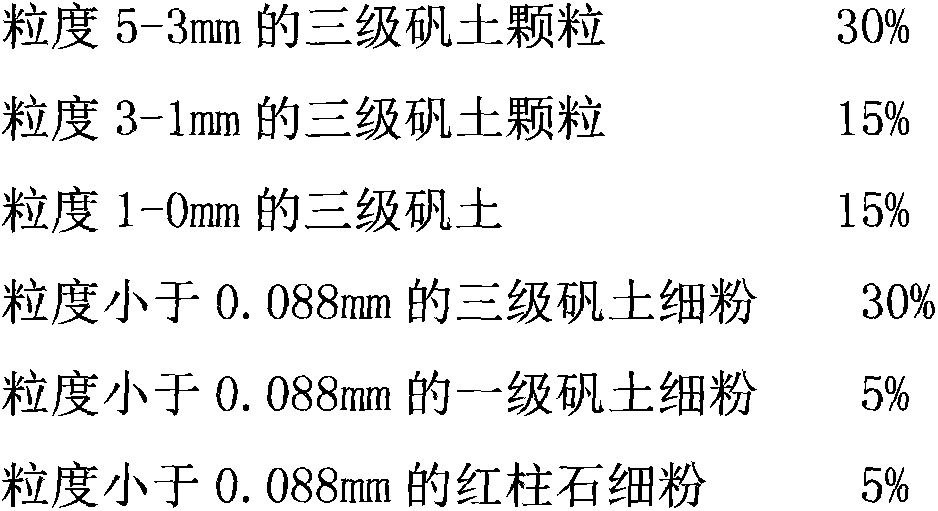

[0019] Modified high alumina bricks for the cold end of the decomposition zone and transition zone of cement kilns, in terms of weight percentage, include the following preparation materials:

[0020] 35% bauxite particles with a particle size of 5-3mm

[0021] 15% tertiary alumina particles with a particle size of 3-1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com