Special-shaped glass fiber and preparation method thereof

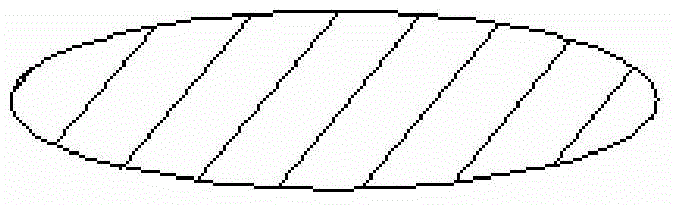

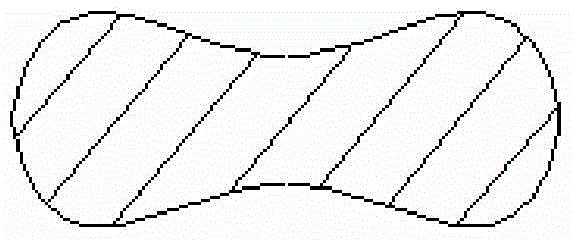

A technology of special-shaped glass fiber and special-shaped ratio is applied in the field of special-shaped glass fiber and its preparation, which can solve the problems of high density and high-speed information processing and high dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a method for preparing the special-shaped glass fiber described in the above technical solution, which is characterized in that it comprises the following steps:

[0059] a) mixing the components included in the special-shaped glass fiber described in the above technical solution, and melting to obtain high-temperature molten glass;

[0060] b) Flowing the high-temperature molten glass through a bushing, cooling, wetting and winding in sequence to obtain special-shaped glass fibers.

[0061] In the present invention, the components included in the special-shaped glass fiber described in the above technical solution are mixed and melted to obtain high-temperature molten glass. The components included in the special-shaped glass fiber are the same as those described in the above technical solution, and will not be repeated here. The present invention has no special limitation on the sources of all raw materials, which can be commercial...

Embodiment 1

[0084] (1) Take raw materials according to the components and molar content of Example 1 in Table 1, mix them in a refractory unit furnace, heat them at 1468°C, then clarify them for 24 hours, and then use forced stirring to homogenize to obtain high-temperature glass liquid.

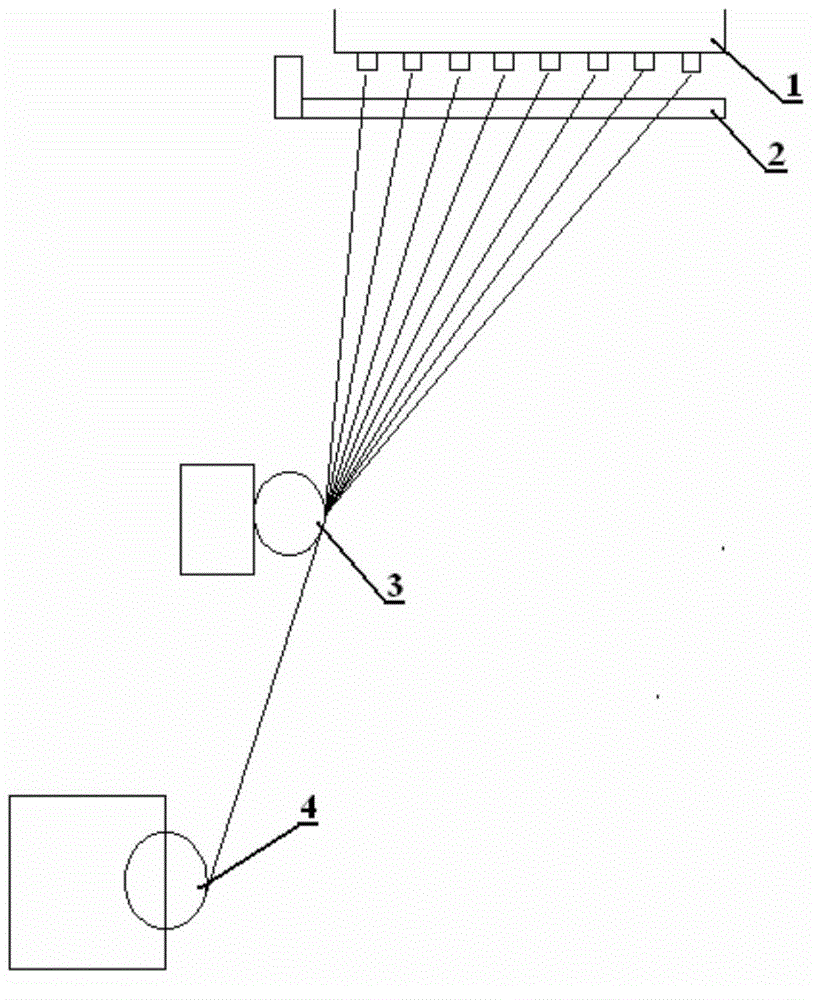

[0085] (2) the obtained high-temperature molten glass is subjected to Figure 4The bushing shown in the figure flows out, sprays and cools at 1320°C to obtain glass filaments, then impregnates the oiler with a starch-based film-forming agent, and finally winds them through a wire drawing machine to obtain special-shaped glass fibers.

Embodiment 2

[0087] (1) Take raw materials according to the components and molar content of Example 2 in Table 1, mix them in a refractory unit furnace, heat them at 1457°C, then clarify them for 24 hours, and then use forced stirring to homogenize to obtain high-temperature glass liquid.

[0088] (2) the obtained high-temperature molten glass is subjected to Figure 4 The bushing shown in the figure flows out, sprays and cools at 1320°C to obtain glass filaments, then impregnates the oiler with a starch-based film-forming agent, and finally winds them through a wire drawing machine to obtain special-shaped glass fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com