Method for removing EDTA (Ethylene Diamine Tetraacetic Acid) in waste water

A waste water and hydrogen peroxide technology, which is applied in metallurgical waste water treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of inability to reuse reclaimed water, prominent problems of equipment and site occupation, and high primary investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In the present embodiment, the effective volume of the oxidation pond is 5m 3 , using a 500W UV lamp. The zinc-nickel alloy electroplating rinsing wastewater of an electroplating enterprise has been measured, and the pollutant content is shown in Table 2 (EDTA and other organic pollutants are represented by COD Cr count):

[0060] Table 2 Contents of various pollutants in rinsing wastewater before and after treatment

[0061]

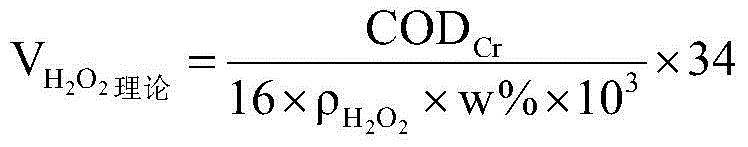

[0062] (1) Oxidation treatment under ultraviolet radiation: Inject 5000L of rinse wastewater into the oxidation pool, first add 1.76kg of CuSO4·5H 2 O, after stirring for 10 minutes, adjust the pH value of the waste water to 2-3, in this embodiment, pH=2.3; open H 2 o 2 Dosing pump, add 28.9L of hydrogen peroxide with a mass percentage concentration of 30%; after the reagent is added, turn on the ultraviolet light, and stir for 30 minutes at a stirring speed of 120r / min;

[0063] (2) Flocculation and sedimentation: the rinsing wastewater ...

Embodiment 2

[0067] In this embodiment, the effective volume of the oxidation tank is 10m 3 , using two 500W UV lamps. The copper-nickel alloy electroplating rinsing wastewater of an electroplating enterprise, the detection data of various pollutants are shown in Table 3 (EDTA and other organic pollutants are represented by COD Cr count):

[0068] Table 3 Contents of various pollutants in rinsing wastewater before and after treatment

[0069]

[0070] (1) Oxidation treatment under ultraviolet radiation: Inject 10,000L of rinsing wastewater into the oxidation tank. Since it already contains heavy metal copper, there is no need to add CuSO 4 ·5H 2 O, directly adjust the pH value of the solution to 2-3, in this embodiment, pH=2.1; open H 2 o 2 Dosing pump, add 43.84L of hydrogen peroxide with a mass percentage concentration of 30%; turn on the ultraviolet light, and stir and react for 30min at a stirring speed of 120r / min;

[0071] (2) Flocculation and sedimentation: the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com