Polycrystalline silicon production method and equipment based on improved Siemens method

A production method, the technology of the Siemens method, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high production cost of polysilicon, affecting the primary conversion rate of trichlorosilane, and low purity of trichlorosilane, etc. Reach the effect of reducing production cost, improving primary conversion rate and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

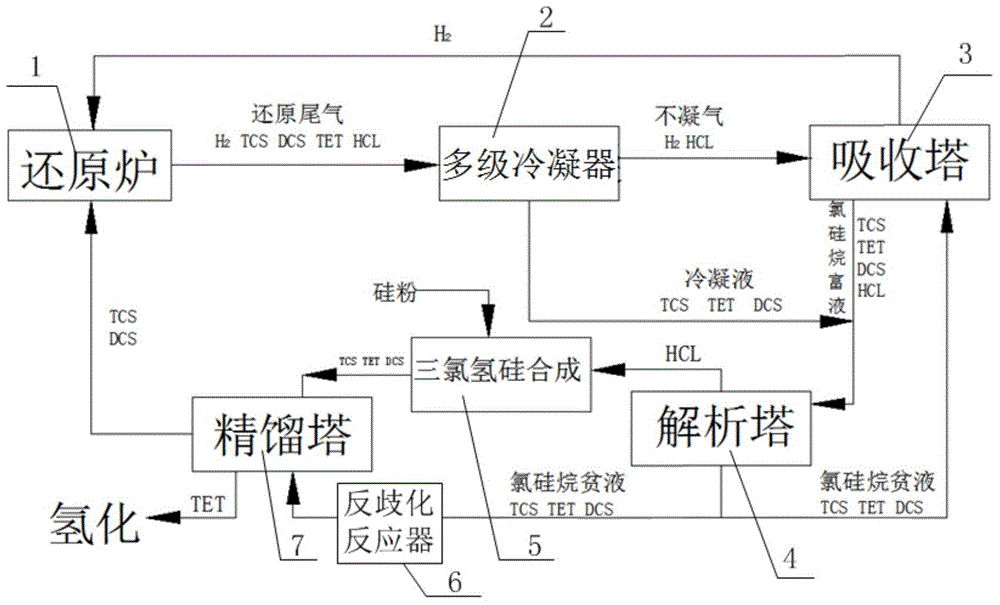

[0039] Such as figure 1 As shown, the embodiment of the present invention provides a polysilicon production method based on the improved Siemens method, comprising the following steps:

[0040] Step 1, trichlorosilane in H 2 Polysilicon is obtained by reducing and depositing in a reduction furnace in an atmosphere, and the reduction furnace exhausts tail gas; the composition of the tail gas is H 2 , HCl, dichlorodihydrosilane, trichlorosilane, chlorosilane.

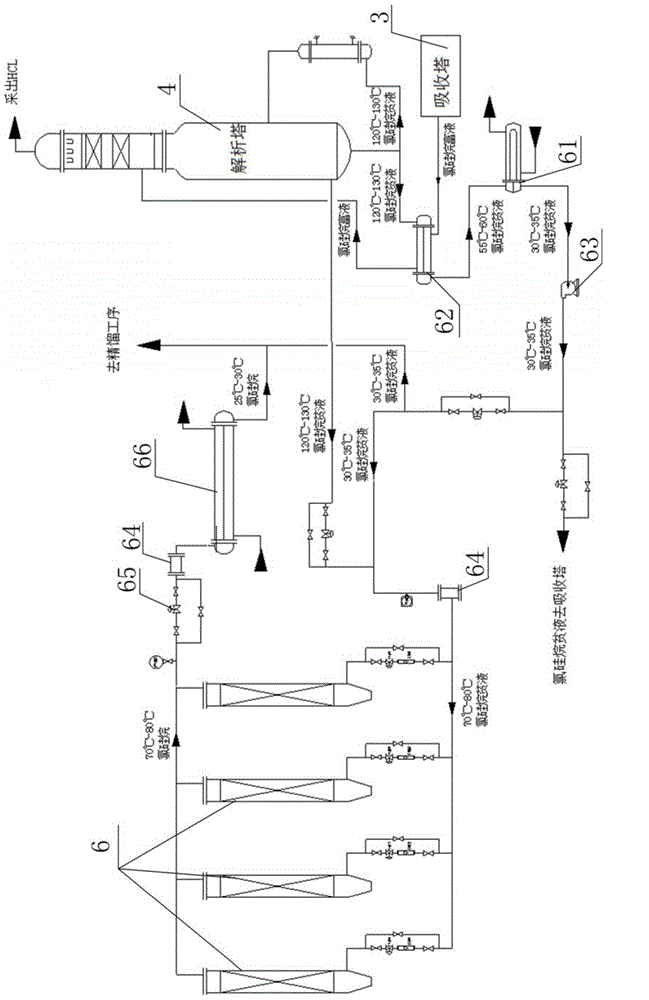

[0041] Step 2, the tail gas in step 1 is multi-stage condensed to obtain non-condensable gas and condensate, the non-condensable gas enters the absorption tower, the absorption tower absorbs the HCL in the non-condensable gas and flows out of the chlorosilane-rich liquid; the condensate is mixed with the chlorosilane-rich liquid After entering the analysis tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com