Automatic tracking method and automatic tracking device of lifter

A kind of crane and automatic technology, applied in the direction of transportation and packaging, load hanging components, etc., to achieve the effect of being conducive to safe production, simple lifting process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described below in conjunction with specific embodiments.

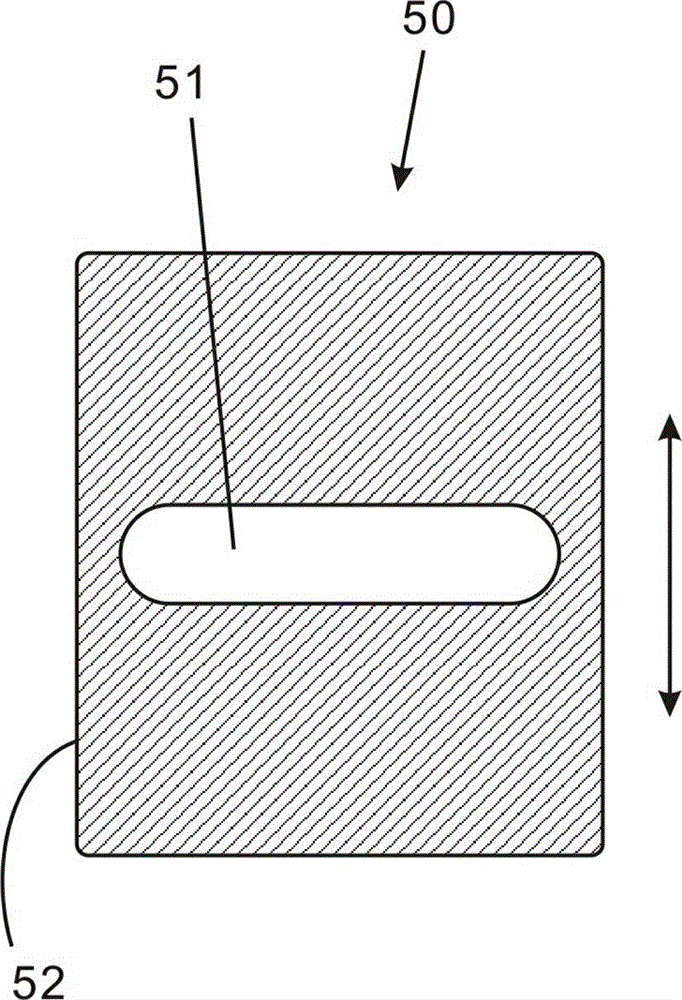

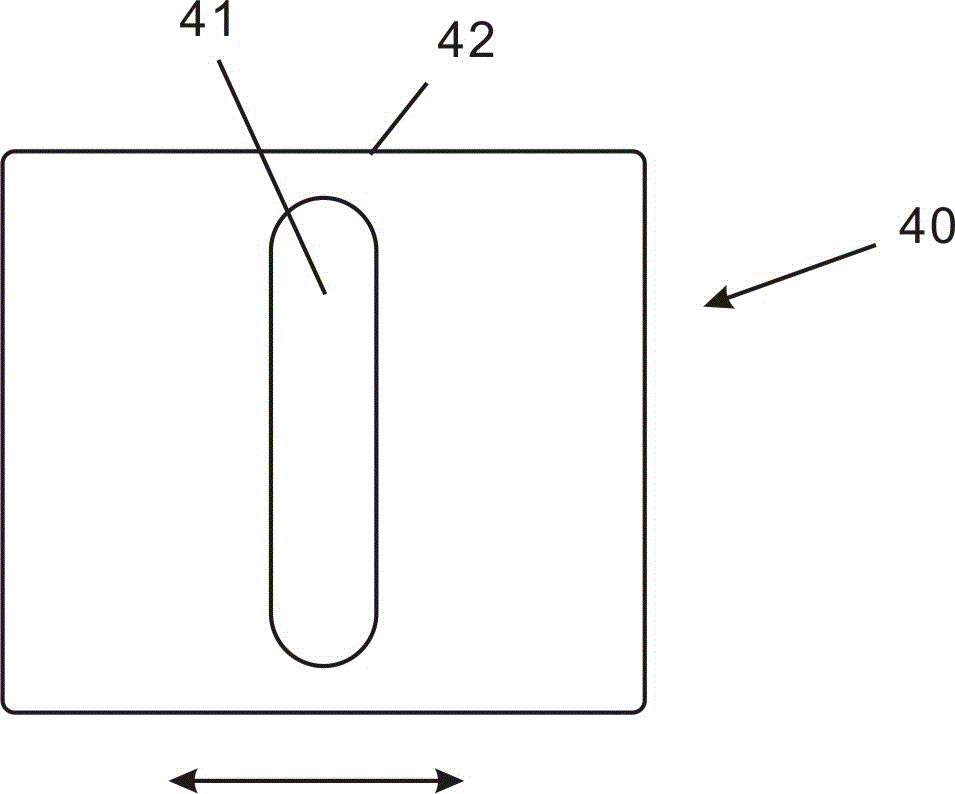

[0041] Such as Figure 1 to Figure 7 The best implementation mode shown implements a method for automatic tracking of a crane, including the following steps:

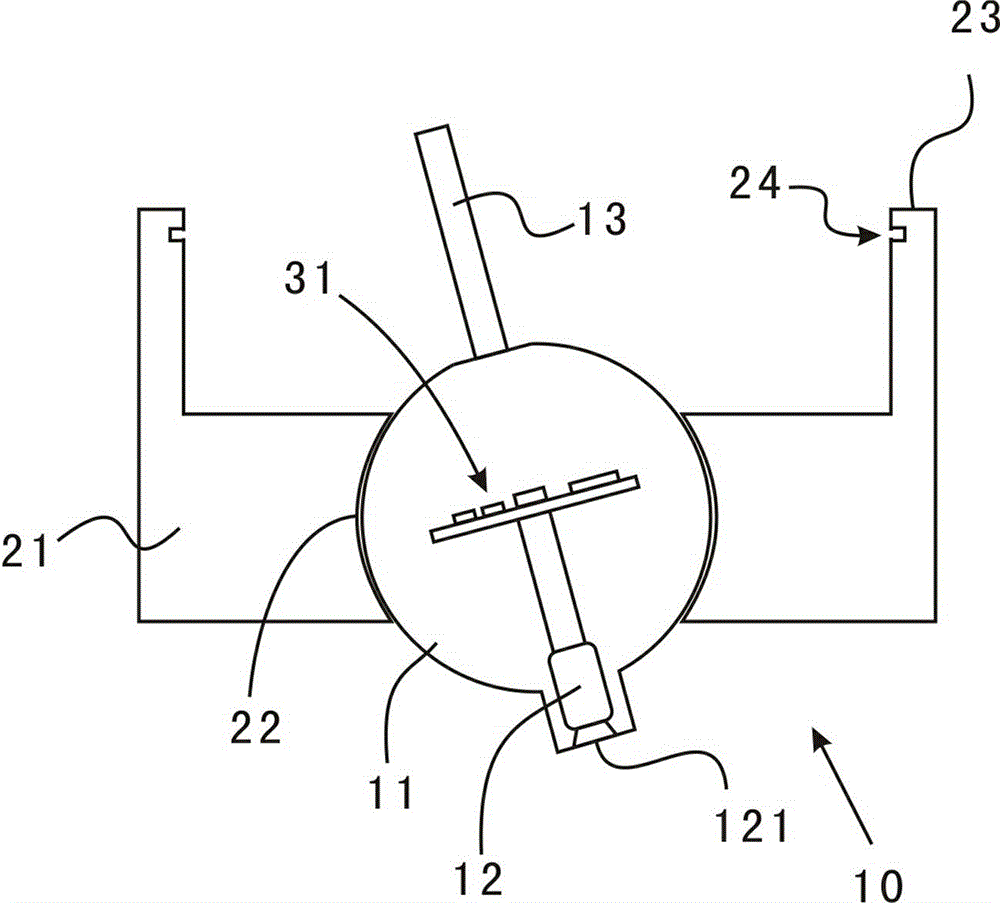

[0042] S1. First, manufacture an optical tracking head 10 and place it on the lifting hoist head of a beam crane. The lifting hoist head is driven by a horizontal driving device and moves in the workshop; a spherical detection is set in the optical tracking head 10 device 11, the spherical detector 11 is held by the slide holder 21, and rotates in its concave inner groove;

[0043] S2. Then, an electronic circuit board 31 and a photoelectric sensor 12 are fixedly arranged in the inner cavity of the spherical detector 11, and the lighting port 121 of the photoelectric sensor 12 faces the ground below;

[0044] The electronic circuit panel 31 is parallel to the daylight opening 121, and the angle between the two and the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com