Suspension type universal conveying rack

A conveying frame and suspension technology, applied in the field of suspended universal conveying frame, can solve problems such as work site blockage, package dropping, and affecting loading efficiency, so as to reduce workload, reduce falling, and improve conveying and transshipment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

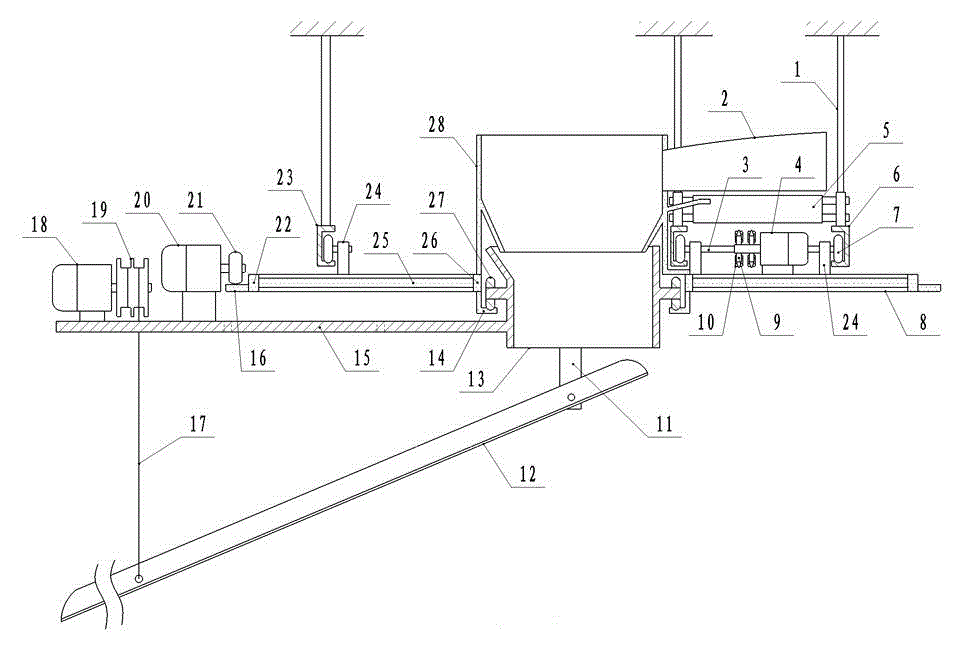

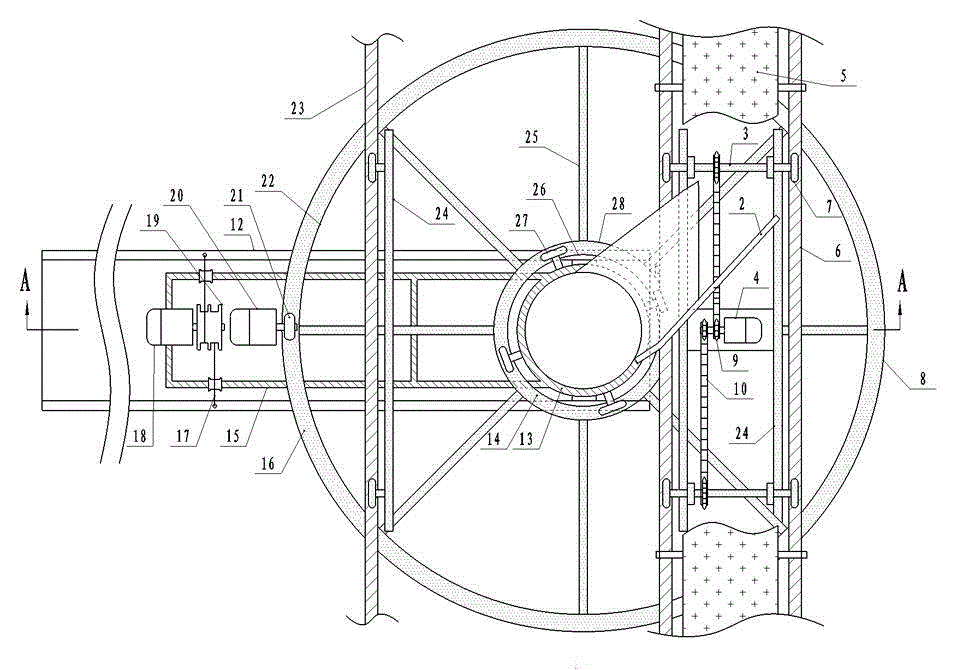

[0011] Example: such as figure 1 and figure 2 As shown, a suspension type universal conveying frame is provided with a translational conveying track 6 and a balance track 23 above the conveying site, a hanger 1 is installed above the track, and a conveyor belt 5 for goods is installed above the inner side of the conveying track 6 ;

[0012] Below the conveying track 6, a disc-shaped translation frame 8 is installed. The translation frame 8 is composed of an inner ring 26, an outer ring 22 and a fixing bar 25 connecting the inner and outer rings. On the fixing bar 25, a cross bar 24 is installed. Rollers 7 are installed above the two ends of the roller, and the rollers 7 are positioned and installed on the delivery track 6 and the balance track 23. The left and right rollers 7 on the delivery track 6 are installed on a rotating shaft 3, and the rotating shaft 3 is installed on the cross bar 24. The middle part of the rotating shaft 3 is equipped with a sprocket wheel, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com