Efficient solid material reservoir bottom comb type material pusher

A material warehouse and pusher technology, applied in the field of unloading devices, can solve the problems of unsuitable unloading devices at the bottom of the warehouse, agglomeration of materials in the warehouse, low unloading output, etc., and achieves low sensitivity to physical and chemical characteristics, The effect of safe and reliable operation and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

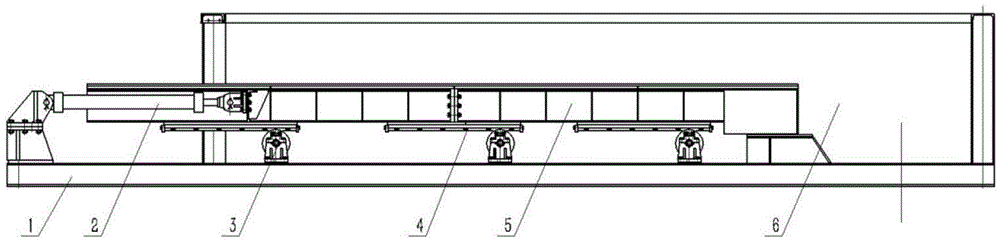

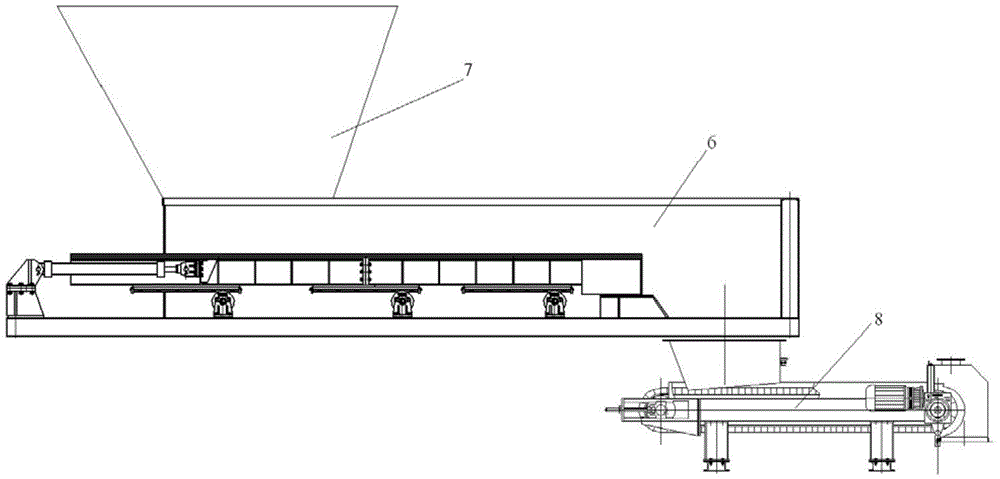

[0021] Such as Figure 1-Figure 3 As shown, the high-efficiency solid material storage bottom grate pusher of the present invention includes a fixed base 1, a housing 6 mounted on the fixed base 1 and a grate bed arranged horizontally.

[0022] The front end of the housing 6 is provided with a material inlet, and the tail end is provided with a discharge port. The material inlet of the housing 6 is connected to the material warehouse 7 , and the material outlet of the housing 6 is connected to the conveyor belt 8 . The grate bed includes a plurality of independently moving push plates 5, each of which is connected to a different drive device 2, and the drive device 2 drives the push plates 5 to perform reciprocating mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com