Track breaking monitoring system of high-speed railway

A high-speed railway and monitoring system technology, which is applied in the direction of railway vehicle shape measuring devices, railway car body parts, railway auxiliary equipment, etc., can solve the problems of poor detection accuracy, shallow detection depth, and no solution proposed, and achieve good stability , Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

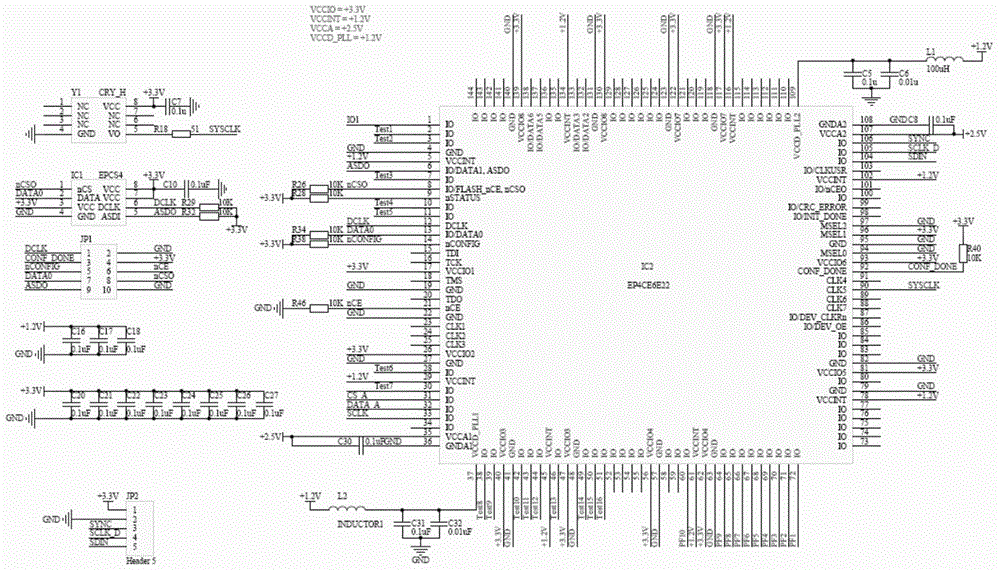

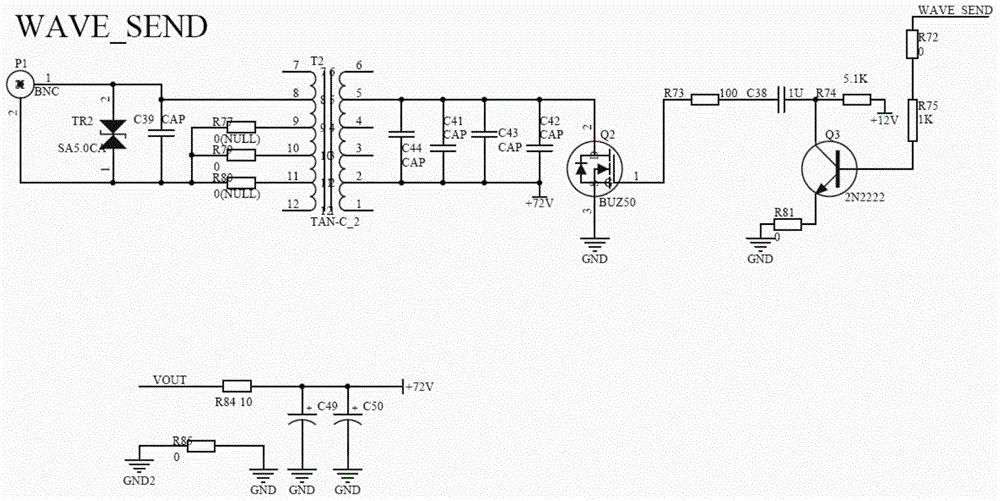

[0058] combine figure 1 The schematic diagram of the structure of the high-speed railway track breaking monitoring system provided by the embodiment of the present invention and Figure 2-Figure 16 The specific circuit diagram in the broken track monitoring system of the high-speed railway shown is described in detail to the broken track monitoring system of the high-speed railway track provided by the present invention, and specific embodiments are as follows:

[0059] The invention provides a high-speed railway broken track monitoring system, such as figure 1 As shown, it includes: micro control unit MCU11 (Micro Controller Unit, Chinese name micro control unit), FPGA (Field Programmable Gate Array, Field Programmable Gate Array) processing circuit, ultrasonic sending probe 13 and ultrasonic receiving probe 14;

[0060] MCU11 is used to generate test signal according to the instruction information received, and test signal is sent to ultrasonic sending probe 13; The ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com