Semi-steel radial tire blank

A radial tire and tire technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as tire damage, affecting driving safety, tearing or stretching, etc., to enhance tread resistance. Grinding, avoiding quality hazards, enhancing the effect of structure and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

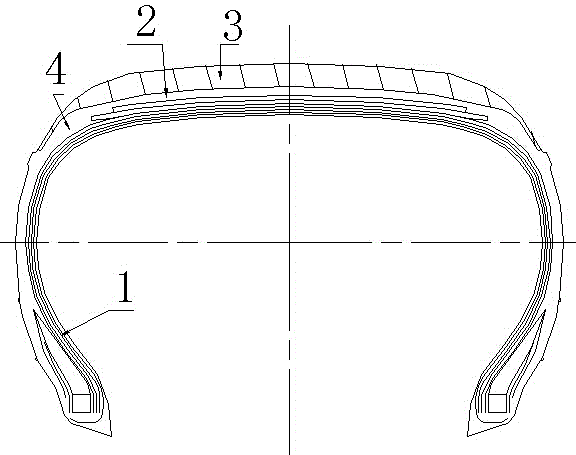

[0013] The present invention as figure 1 , 2 shown.

[0014] A semi-steel radial tire blank, including a tire body 1, a tread 2, and a sidewall 4, the tread 2 adopts a rubber strip 3 winding structure, that is, a single rubber strip 3 is used on the tire body 1 with the sidewall 4 as the The starting point is wound sequentially along the tire circumferential direction, and each adjacent rubber strip is arranged in a close-fitting or inclined stacking manner. The tail end of a single rubber strip 3 is on the other side of the sidewall 4, and finally vulcanized into an integral tire blank.

[0015] The present invention uses a winding device to arrange adhesive strips in a close-fitting arrangement or inclined-plane stacking arrangement for adhesion and winding. During the adhesion and winding, the overlapping range can be adjusted according to structural requirements.

[0016] Among them, the width of the rubber strips can be adjusted according to the process requirements. By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com