A kind of material processing method of bamboo root products

A material processing and product technology, which is applied in wood processing, wood processing details, impregnating wood, etc., can solve the problems of incomplete processing effect, unenvironmental protection, easy mold, moth, and cracking of bamboo, so as to improve the quality and processing performance, The effect of ensuring quality, improving quality and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

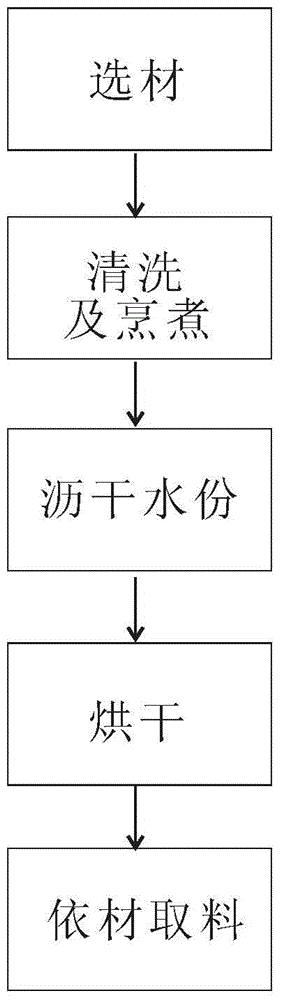

[0022] Such as figure 1 Shown, a kind of material processing method of bamboo root product is characterized in that comprising the following steps:

[0023] Step 1. Material selection. Excavate fresh bamboo roots that grow in deep mountains and old forests, and the selected bamboo roots are more than four years old;

[0024] Step 2. Wash and cook. Wash the bamboo roots, put them in an iron pot, add water, and immerse all the bamboo roots in the water, then heat and cook, add 5% salt, 10% honeysuckle leaves, and 2% tea stalks to the water according to the weight ratio , 0.1% of red pepper, 2% of alum, 2% of borax, cook with slow fire, control the water temperature rise rate at 10°C / hour, when the water temperature rises to 100°C, keep it for 2 hours and gradually reduce the firepower, Slowly cool down, and when the water temperature drops to 60°C, take out the bamboo roots;

[0025] Step 3. Drain the water. The bamboo roots are hung in a cool and ventilated place for 8 hou...

Embodiment 2

[0030] In step 2, the weight ratio of adding salt is 3%, honeysuckle leaf is 9%, tea stem is 1%, red pepper is 0.08%, alum is 1%, borax is 1%, and the water temperature rises when cooking and heating The speed is controlled at 9°C / hour. When the water temperature rises to 100°C, keep for 1 hour to gradually reduce the firepower, and slowly lower the temperature. When the water temperature drops to 45°C, take out the bamboo roots. All the other are with embodiment 1.

Embodiment 3

[0032] In step 2, the weight ratio of adding salt is 6%, honeysuckle leaf is 12%, tea stem is 3%, red pepper is 0.12%, alum is 3%, borax is 3%, and the water temperature rises when cooking and heating The speed is controlled at 8°C / hour. When the water temperature rises to 100°C, keep for 1 hour and gradually reduce the firepower, and slowly lower the temperature. When the water temperature drops to 50°C, take out the bamboo roots. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com