Sheet metal stamping device

A sheet metal stamping and stamping machine technology, applied in the field of stamping, can solve the problems of high cost, inconvenient installation, complex structure, etc., and achieve the effect of reducing vibration and stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the implementation and accompanying drawings.

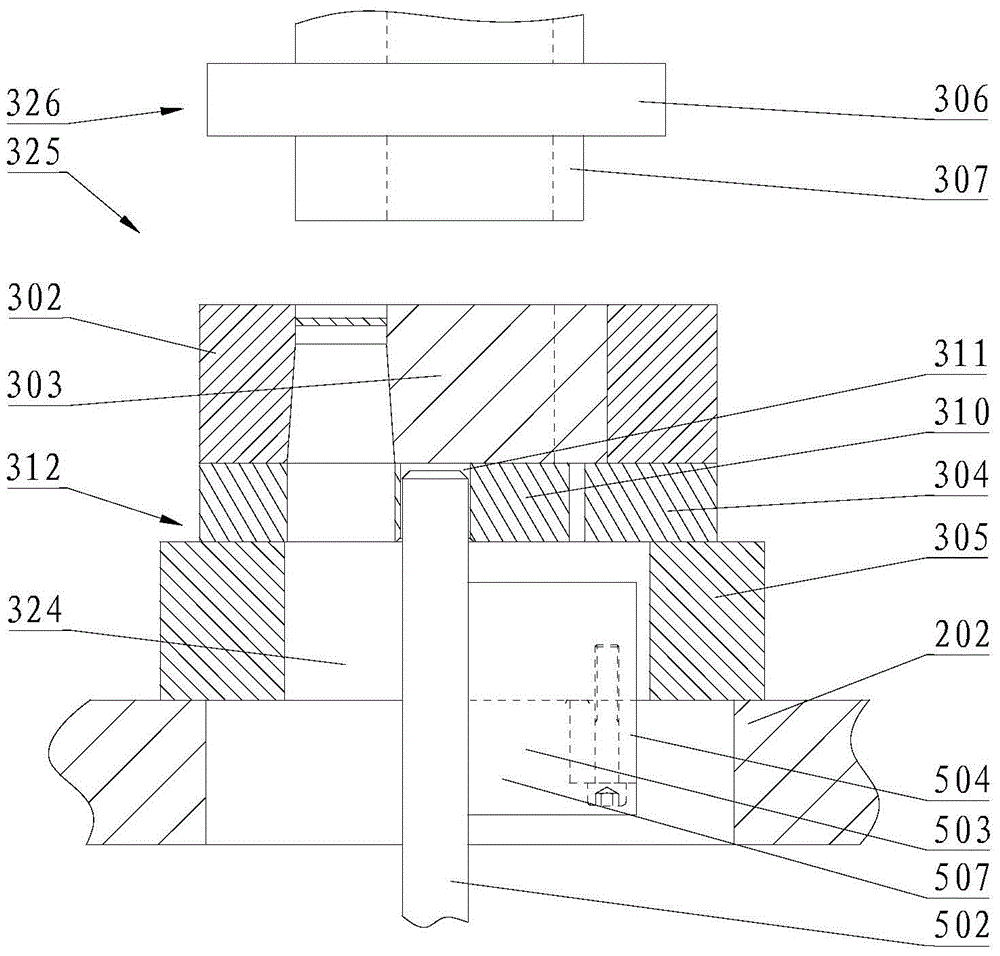

[0026] The most critical idea of the present invention is that the opening of the groove on the fixed molded part and the insert of the groove of the die are designed to be rotationally connected, and the two have a lateral rotation gap at the joint, which can make better use of the groove of the die The side insert is subjected to lateral force, so as to better avoid or reduce the problem of mold damage due to uneven lateral force caused by uneven clearance between both sides of the cutting edge.

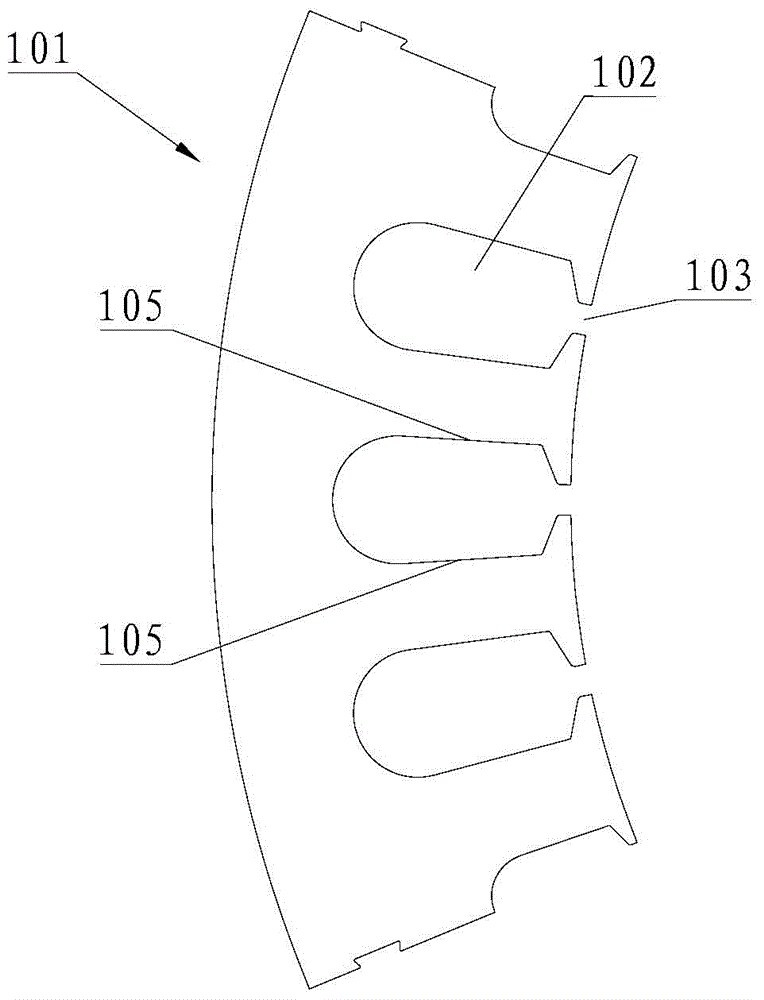

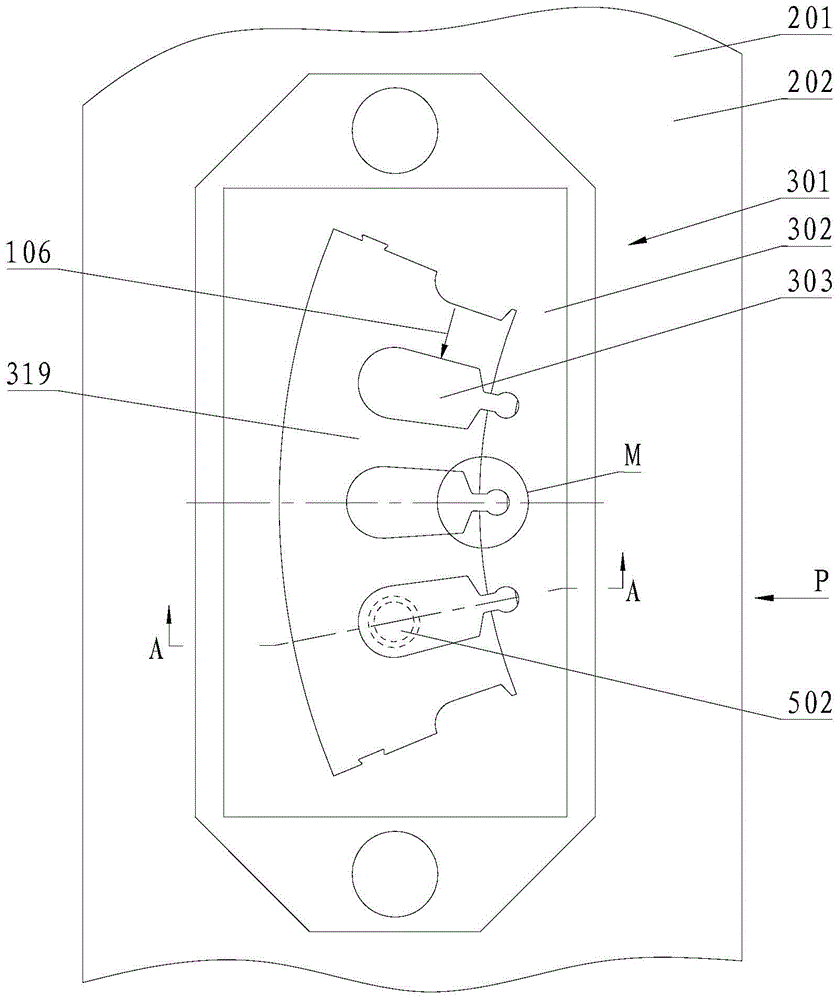

[0027] see Figure 1 to Figure 4 , a sheet metal stamping device, including a stamping machine platform 201 and a stamping die 301 located on the stamping machine platform 201, the stamping die 301 includes a fixed mold forming part 325 and a movable mold form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com