Pretreatment equipment for mechanical component rust prevention technology

A technology for mechanical parts and processing equipment, which is applied in the field of pre-processing equipment for the anti-rust process of mechanical parts, can solve the problems of difficulty in ensuring the uniformity of cleaning agent spraying and drying, and difficulty in ensuring the anti-rust process treatment, and achieves improvement. effect, the effect of avoiding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

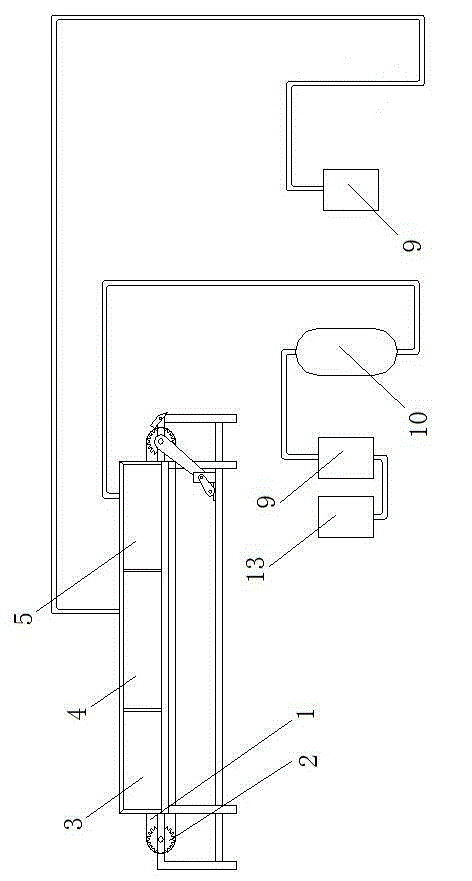

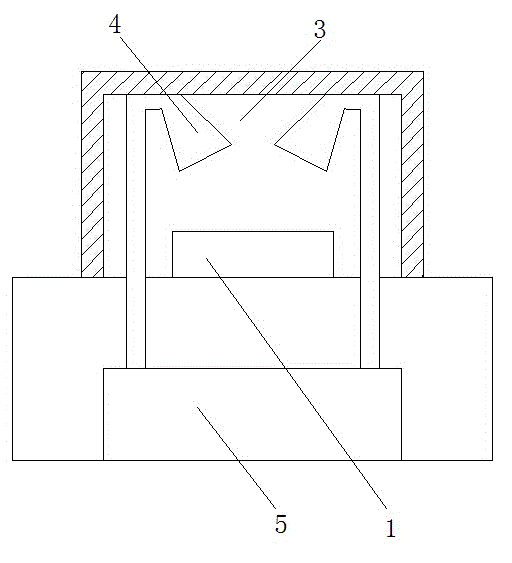

[0019] Such as figure 1 Shown is a pre-processing equipment for the antirust process of mechanical parts, which includes a transmission device, a cleaning device and a drying device; the transmission device includes a transmission belt 1, which consists of a The sprocket 2 is driven; the cleaning device includes a cleaning chamber 3, a plurality of cleaning nozzles 4 are arranged in the cleaning chamber 3, and it is communicated with a cleaning agent tank 5 arranged on the outside of the cleaning chamber; the drying device includes two three drying chambers, which are sequentially distributed in the forward direction of the conveyor belt, wherein the drying chambers sequentially distributed along the forward direction of the conveyor belt 1 are the first drying chamber 6 and the second drying chamber 7; There are a plurality of drying nozzles 8 in the room, which are connected to the air compressor 9 arranged outside the drying chamber; wherein, the air compressor 9 correspond...

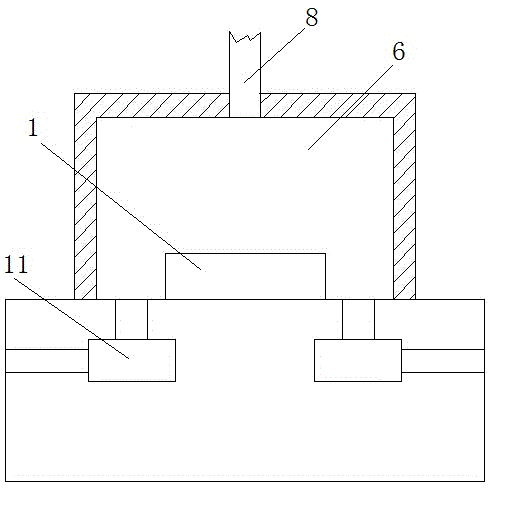

Embodiment 2

[0024] As an improvement of the present invention, such as image 3 and Figure 4 As shown, both the first drying chamber 6 and the second drying chamber 7 are provided with vacuum adsorption pumps 11 . With the above design, it can achieve thorough drying of mechanical parts through multiple drying chambers. At the same time, the vacuum adsorption pumps in multiple drying chambers can homogenize the flow direction of the airflow in the drying chamber, so that its Drying efficiency is improved.

[0025] As an improvement of the present invention, such as image 3 As shown, in the first drying chamber 6 , the vacuum suction pump 11 is arranged on the bottom end surface of the first drying chamber 6 , and it is located outside the projection of the conveyor belt 1 on the bottom end surface of the first drying chamber 6 . With the above design, it can make the air flow in the first drying chamber move from top to bottom, so as to efficiently dry the cleaning agent on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com