Cleaning device for silica gel plate of solar cell laminating machine

A solar cell and cleaning device technology, applied in the field of solar cells, can solve problems such as unclean cleaning of residual materials, inability to expand and contract, hidden dangers of product quality, etc., and achieve good cleaning effect, easy operation, and convenient cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

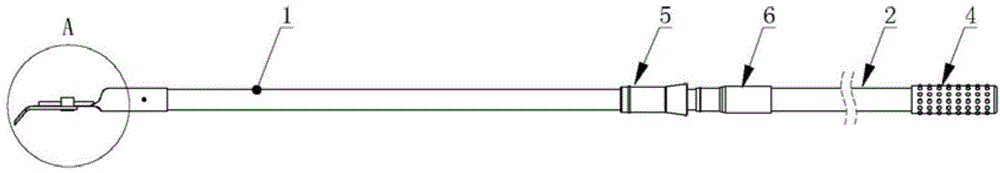

[0021] Such as Figure 1~2 As shown, a silicone plate cleaning device for a solar battery laminator includes a straight rod, a telescopic sleeve, and a cleaning sheet device. The straight rod includes an inner tube 1, an outer tube 2, and a tube connector 3. The inner tube 1 is connected in the outer tube 2 through a telescopic sleeve, and the cleaning sheet device is connected to the end of the inner tube 1 through a tube connector. The end of the outer tube 2 is provided with an outer tube cap 4 . The telescopic sleeve includes a telescopic sleeve a5 and a telescopic sleeve b6 connected to each other, the inner tube 1 is sleeved in the telescopic sleeve a5, and the outer tube 2 is sleeved in the telescopic sleeve b6.

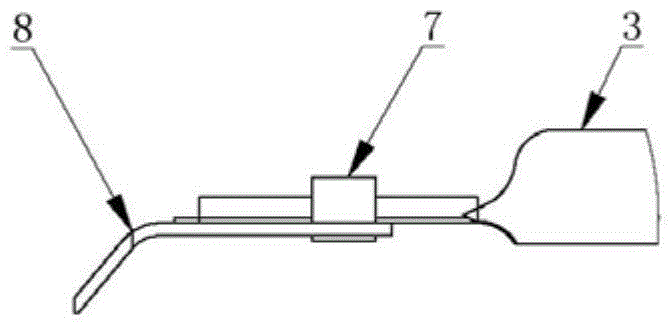

[0022] The cleaning sheet device includes a fixing clip 7 and a cleaning sheet 8 , and the cleaning sheet 8 is fixed on the pipe connector 3 through the fixing clip 7 . One end of the cleaning sheet 8 is fixed on the fixing clip 7, and the other end is bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com