CIT disinfection type biological safety cabinet

A technology of biological safety cabinets and cabinets, which is applied in laboratory utensils, shells or chambers, chemical instruments and methods, etc., can solve the problems of easy clogging of high-efficiency filtration membranes, increasing the danger of safety cabinets, and lack of killing. , to reduce maintenance times and risks, improve filtration rate and service life, and reduce risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

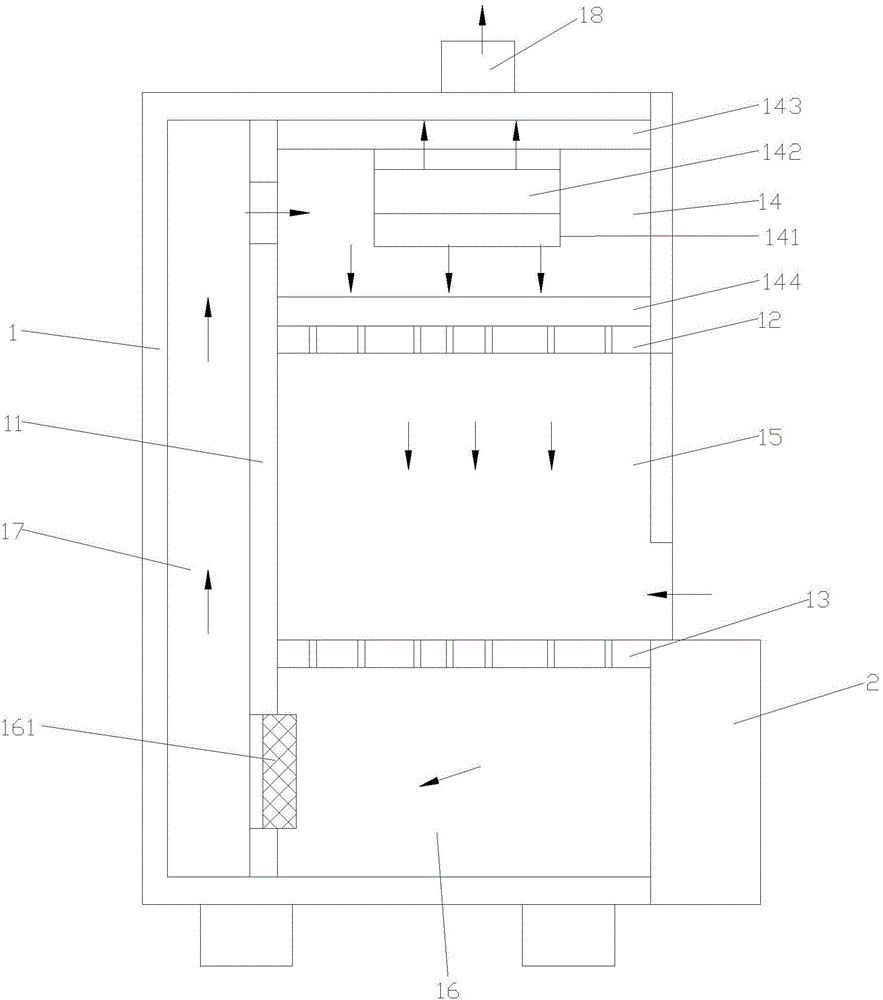

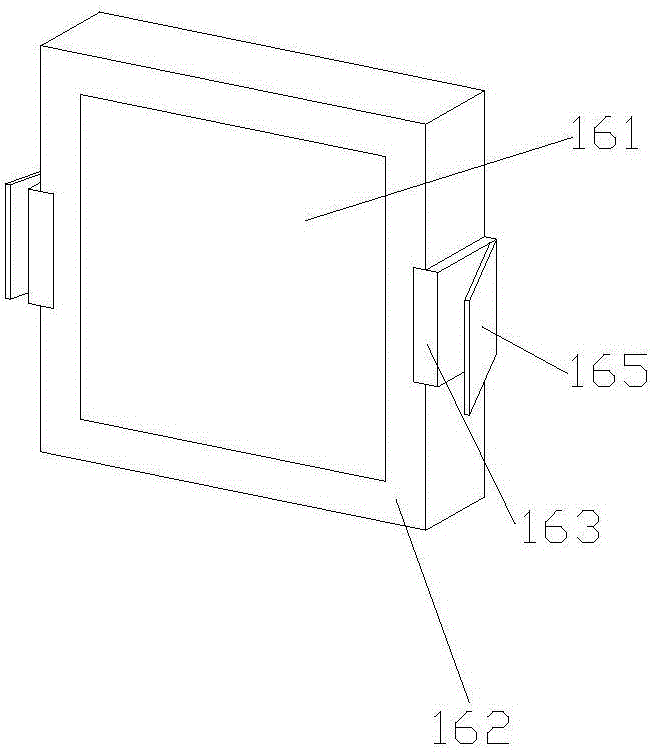

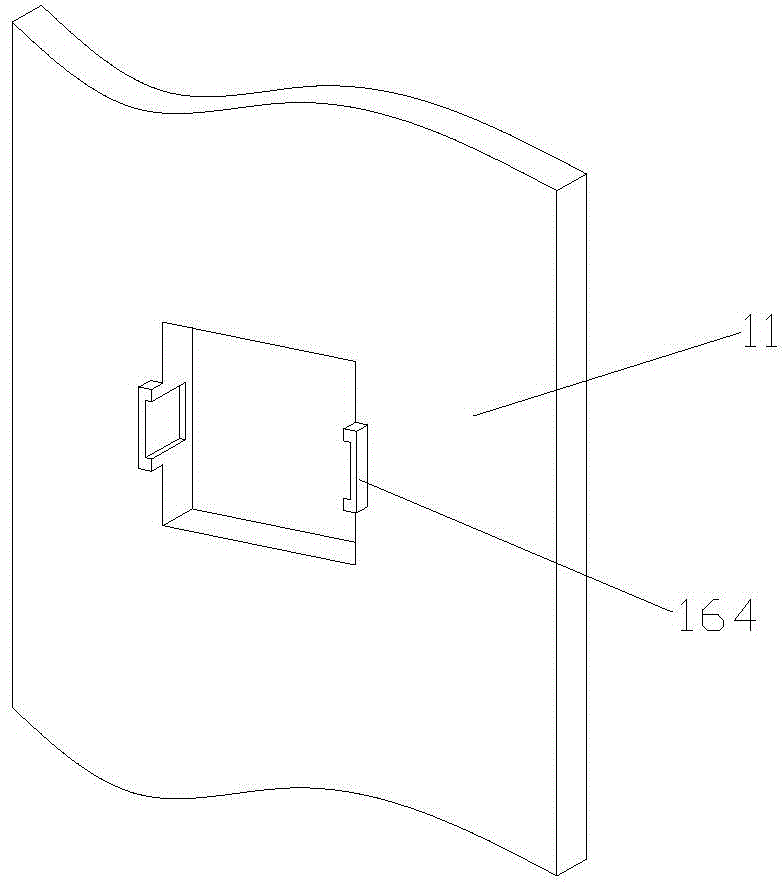

[0014] Such as figure 1 , figure 2 , image 3 as shown, figure 1 It is a structural representation of a CIT disinfection type biological safety cabinet proposed by the present invention; figure 2 It is a structural schematic diagram of an electrostatic dust accumulation device in a CIT disinfection type biological safety cabinet proposed by the present invention; image 3 It is a schematic diagram of the connection structure between the riser and the electrostatic precipitating device in a CIT disinfection type biological safety cabinet proposed by the present invention.

[0015] refer to figure 1 , figure 2 , image 3 , a kind of CIT disinfection type biosafety cabinet that the present invention proposes, comprises cabinet body 1, and cabinet body 1 inner rear side is provided with vertical partition 11 and cabinet body is divided into front cavity and back cavity, and front cavity is provided with parallel setting The upper diaphragm 12 and the lower diaphragm 13 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com