Preparation method of catalytically cracked gasoline hydrodesulfurization catalyst containing nanocrystalline multi-stage duct ZSM-5 molecular sieve

A technology for catalytically cracking gasoline, ZSM-5, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high dispersion of metal active components, desulfurization The efficiency needs to be improved, the specific surface area of the catalyst is large, etc., to achieve the effect of good hydrothermal stability, excellent ion exchange performance, and rich surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

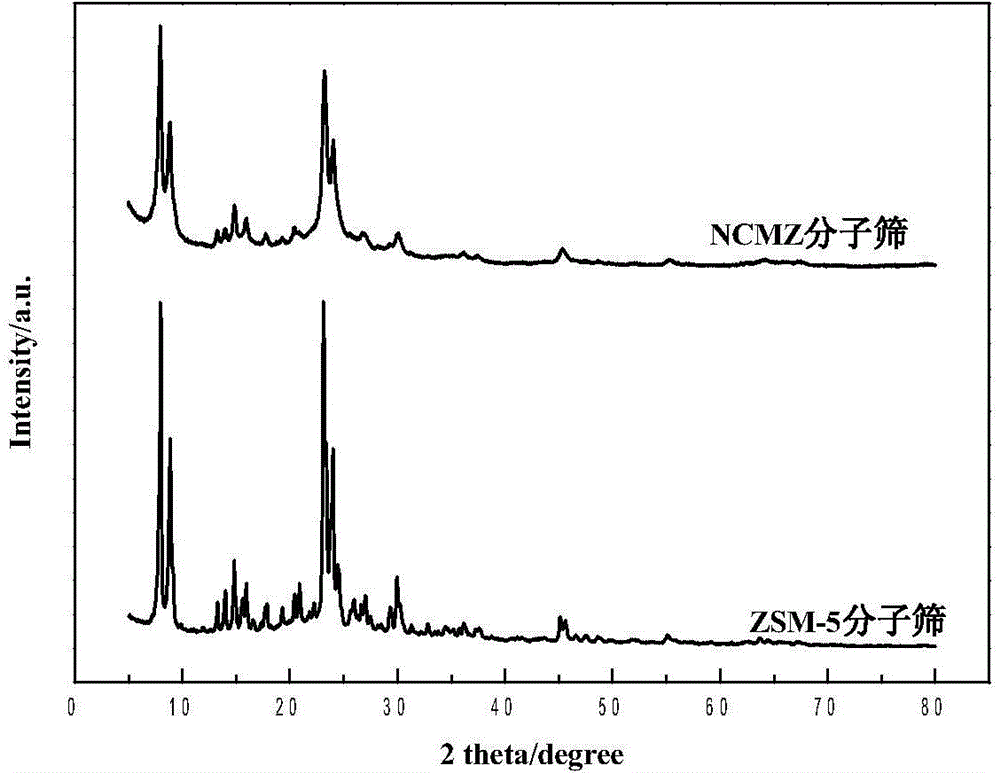

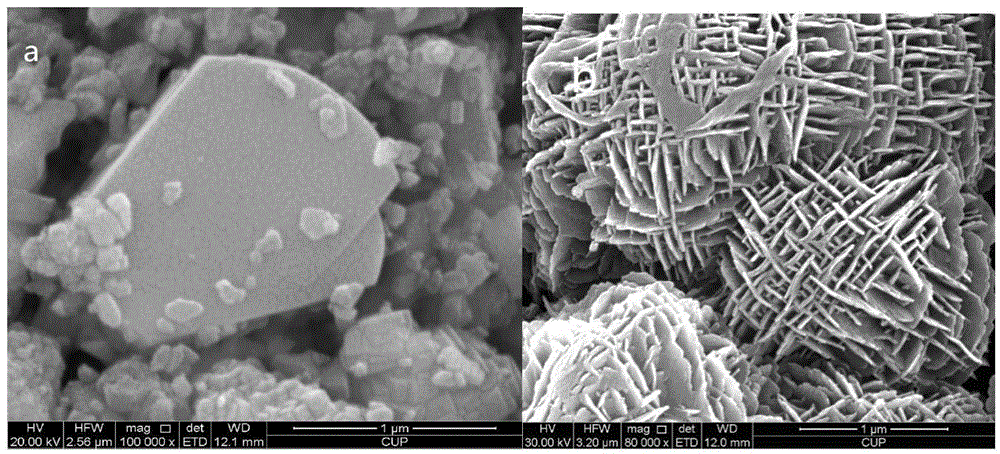

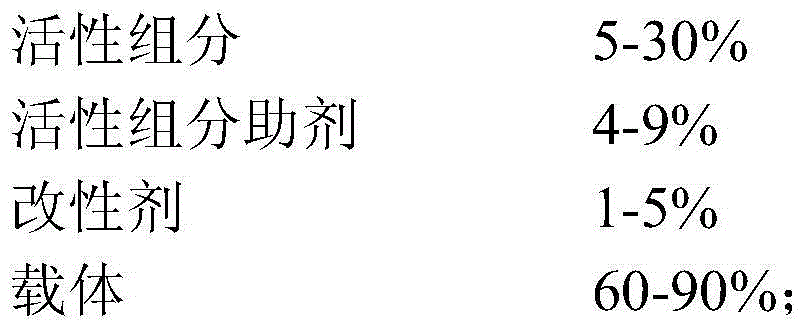

[0030] (1) Preparation of nanocrystalline NCMZ molecular sieves: According to literature (Nature.2009, 461:246-9), nanocrystalline NCMZ molecular sieves were synthesized: 2.37g of sodium hydroxide was dissolved in 61.26g of water, and stirred evenly. Weigh 7.62g C 34 h 74 Br 2 N 2 Add it into the sodium hydroxide solution, continue to stir for 2h, and dissolve 0.98g of octadecadecahydrate aluminum sulfate in 12.8g of sulfuric acid (mass fraction ω=20%), and after stirring for 1h, mix the above two solutions and move to 60 Stir in a water bath for 1 h. Weigh 30.2g of tetraethyl orthosilicate, add it dropwise into the mixed solution, stir for 2 hours, and form a synthetic gel. Move the synthetic rubber to a crystallization kettle with a polytetrafluoroethylene liner, crystallize at 150°C for 5 days, filter, wash, and dry at 110°C for 10 hours, then bake it in an air atmosphere at 550°C for 6 hours to remove the template agent, namely The properties of the nanocrystalline NC...

Embodiment 2

[0034] (1) Preparation of nanocrystalline NCMZ molecular sieve: According to literature (Nature.2009, 461:246-9), nanocrystalline NCMZ molecular sieve was synthesized: 4.74g of sodium hydroxide was dissolved in 122.4g of water, and stirred evenly. Weigh 15.24g C 34 h 74 Br 2 N 2 Add it into the sodium hydroxide solution, continue to stir for 1 h, and dissolve 1.96 g of aluminum sulfate octadecahydrate in 25.6 g of sulfuric acid (mass fraction ω=20%), and after stirring for 0.5 h, mix the above two solutions and move to Stir in a water bath at 60°C for 1h. Weigh 60.4g of tetraethyl orthosilicate, add it dropwise into the mixed solution, and stir for 1 hour to form a synthetic gel. Move the synthetic rubber to a crystallization kettle with a polytetrafluoroethylene liner, crystallize at 150°C for 5 days, filter, wash, and dry at 110°C. After 6h, bake it in an air atmosphere at 550°C for 6h to remove the template. That is, the nanocrystalline-based NCMZ molecular sieve is ob...

Embodiment 3

[0038] (1) Preparation of nanocrystalline NCMZ molecular sieve: According to literature (Nature.2009, 461:246-9), nanocrystalline NCMZ molecular sieve was synthesized: 1.185g of sodium hydroxide was dissolved in 30.63g of water, and stirred evenly. Weigh 3.81g C 34 h 74 Br 2 N 2 Add it into the sodium hydroxide solution, continue to stir for 2h, and dissolve 0.49g of octadecadecahydrate aluminum sulfate in 6.4g of sulfuric acid (mass fraction ω=20%). After stirring for 1h, mix the above two solutions and move to 60 Stir in a water bath for 1 h. Weigh 15.1g of tetraethyl orthosilicate, add it dropwise into the mixed solution, stir for 2 hours, and form a synthetic gel. Move the synthetic glue to a crystallization kettle with a polytetrafluoroethylene liner, crystallize at 150°C for 5 days, filter, wash, and dry at 110°C. After 10 hours, bake it in an air atmosphere at 550°C for 6 hours to remove the template. The obtained nanocrystalline NCMZ molecular sieve;

[0039] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com