Efficient dispersed venturi ejection reactor

A Venturi and reactor technology, which is applied in the field of liquid-liquid two-phase flow mixing reaction equipment, can solve the problems such as the inability to guarantee the degree of dispersion of yellow phosphorus, the cylindrical rotating zone, and the reduction of stirring efficiency, and achieve outstanding sealing performance and sufficient guarantee. Sexual, structural composition simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

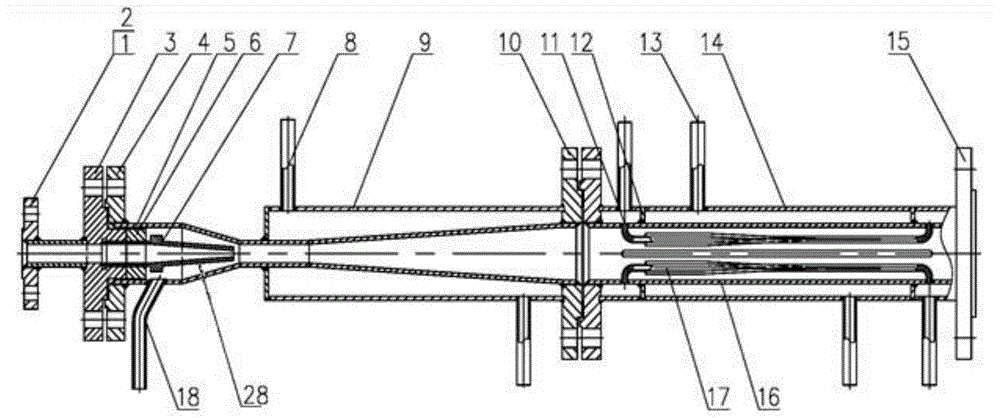

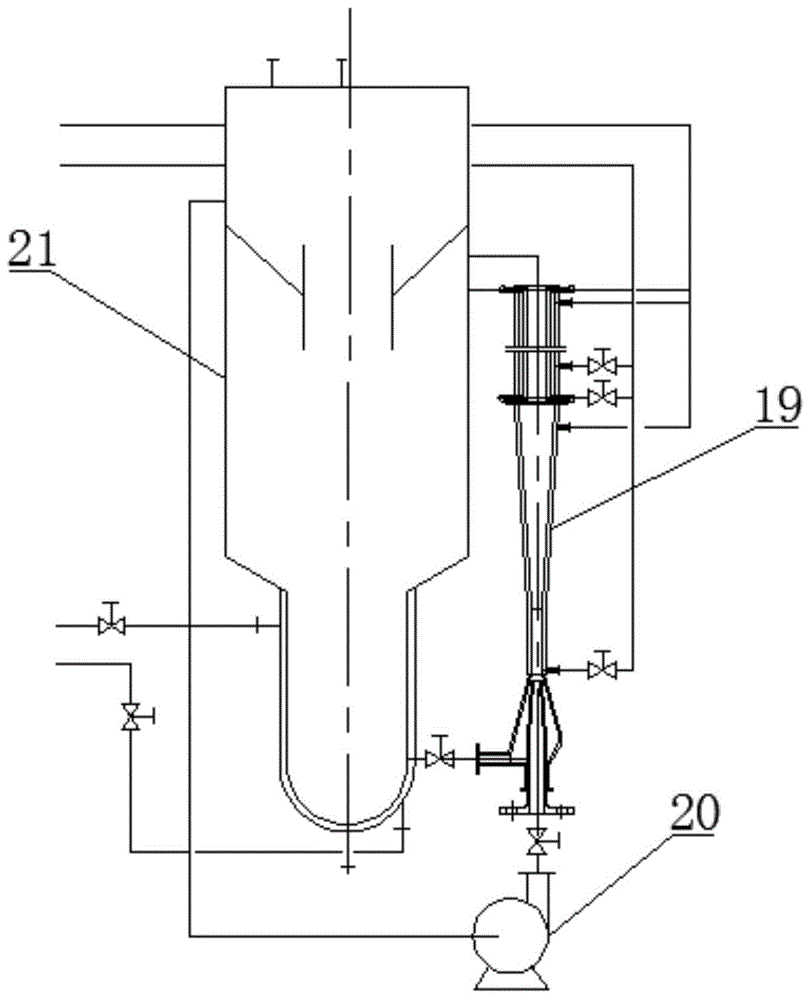

[0034] Such as figure 2 As shown, the yellow phosphorus arsenic removal system mainly consists of a Venturi ejector reactor 19, a phase separator 21, a circulation pump 20 and related adjustment and detection equipment, wherein the Venturi ejector reactor 19 is the main high-speed disperser in the system and mixing reactors.

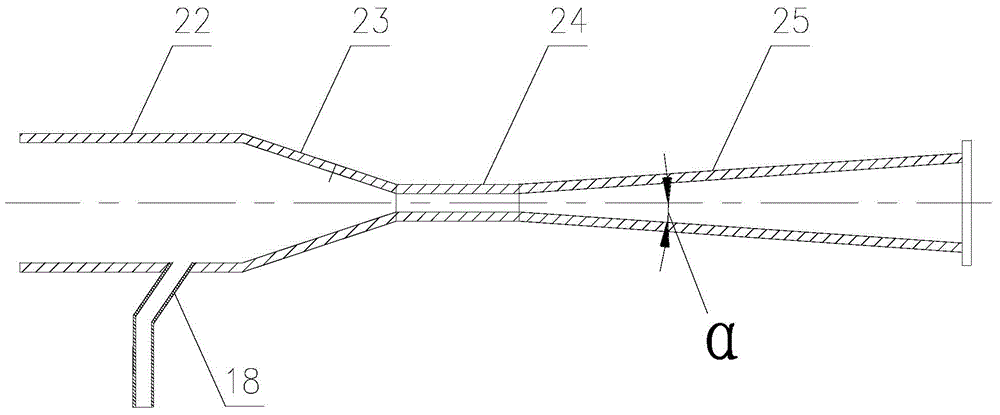

[0035] Such as figure 1 As shown, the venturi injection reactor 19 includes: 1—hydrogen peroxide inlet pipe, 2—inlet pipe flange, 3—non-standard flange, 4—venturi flange, 5—venturi equipment, 6—lock Tight nut, 7—high-speed jet nozzle, 8—hot steam inlet and outlet pipe of Venturi section, 9—Venturi insulation jacket, 10—pipe flange of diffuser section, 11—connection of finned tube and drainage pipe 16, 12— Ring plate, 13—hot steam inlet and outlet pipe of drainage pipe section, 14—insulation jacket of drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com