Desulfurization and dedusting equipment with air intake system

A technology of desulfurization and dust removal equipment and air intake system, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, etc. It can solve the problems of large outflow of lye, pollution, and troublesome discharge of sediments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

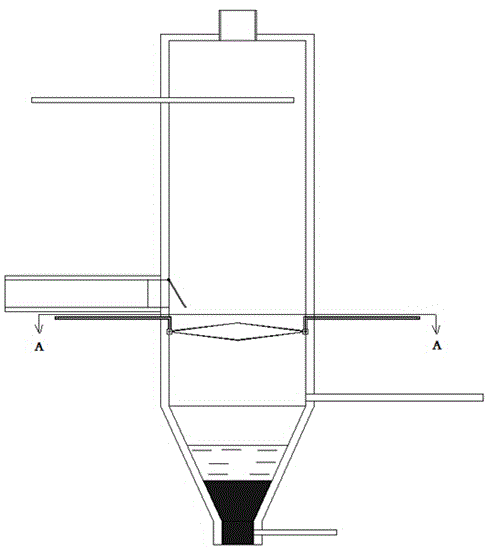

[0013] Combine below Figure 1-5 The present invention will be described in detail.

[0014] The desulfurization and dust removal equipment with air inlet system according to the embodiment of the present invention includes a tank body 1, the tank body 1 is divided into an upper main body part and a lower sediment cone part 6, and the upper main body part is a section It is in the shape of a square regular prism, and the lower part of the sediment cone part 6 is in the shape of a square regular quadrangular prism in cross section. It is a sediment outlet, and an outlet valve 7 is arranged at the sediment outlet; a circulating lye outlet pipe 4 is arranged at the boundary between the main body and the sediment vertebral body, and an lye input pipe 4 is arranged at a position near the top of the main body The spray pipe 3 is provided with a flue gas inlet pipe 5 at the lower part of the middle part of the main body, and the flue gas inlet pipe 5 is equipped with an air inlet sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com