Dust collection device

A technology of dust removal device and pipeline, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., which can solve the problems of smoke and dust polluting the atmosphere, affecting the effect of dust removal, and failure of the filter bag filter function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

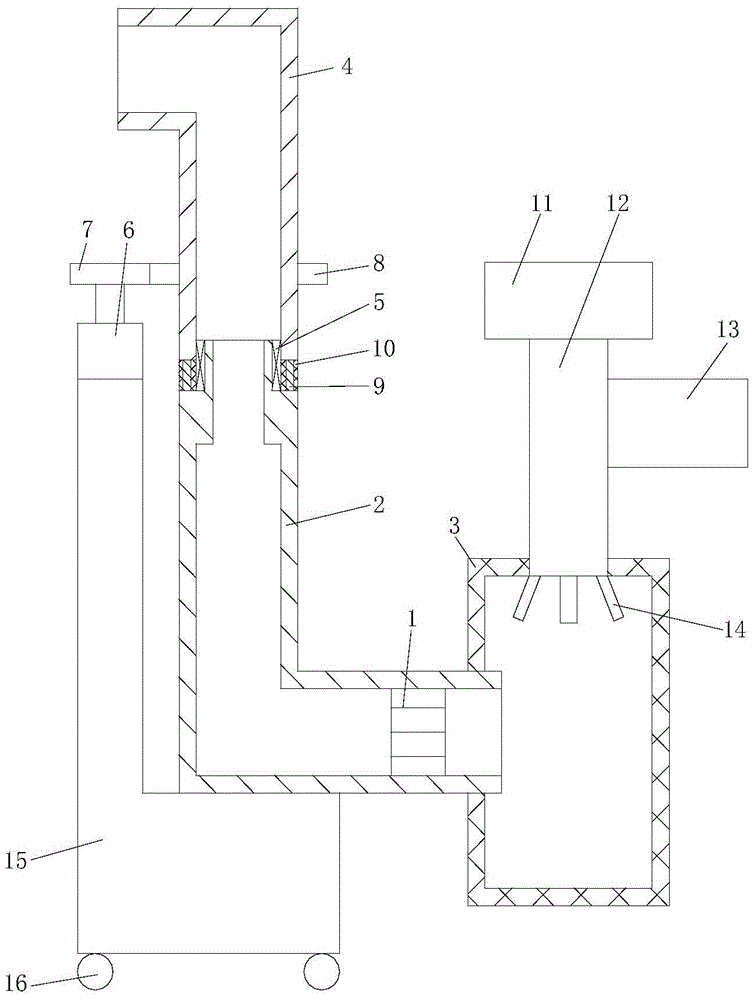

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] refer to figure 1 , a dust removal device of the present invention includes a fan 1, a pipeline 2, a cloth bag 3, a powder storage 11, a screw conveyor 12 and a pressure fan 13. The fan 1 is assembled in the pipeline 2, and the cloth bag 3 is connected with one end of the pipeline 2, and the section of the pipeline 2 is L-shaped. The powder storage 11 is connected to one end of the screw conveyor 12, and the other end of the screw conveyor 12 extends into the cloth bag 3, and the pressure fan 13 is connected to the screw conveyor 12, and the screw conveyor 12 extends into the cloth bag A plurality of sprinkler heads 14 are provided at the end of the wall. It also includes an air intake device and a driving device, the air intake device includes an L-shaped air intake pipe 4 and a bearing 5, the bearing 5 is fixed in the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com