Water purifier with bottom mount and top double row filter cartridge

The technology of a water purifier and machine base is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc. It can solve the problems of increasing the cost of use, affecting the promotion and improvement of water purifiers, and inconvenient problems, so as to reduce Small vertical space, easy to move the machine and replace the filter, and improve the machine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

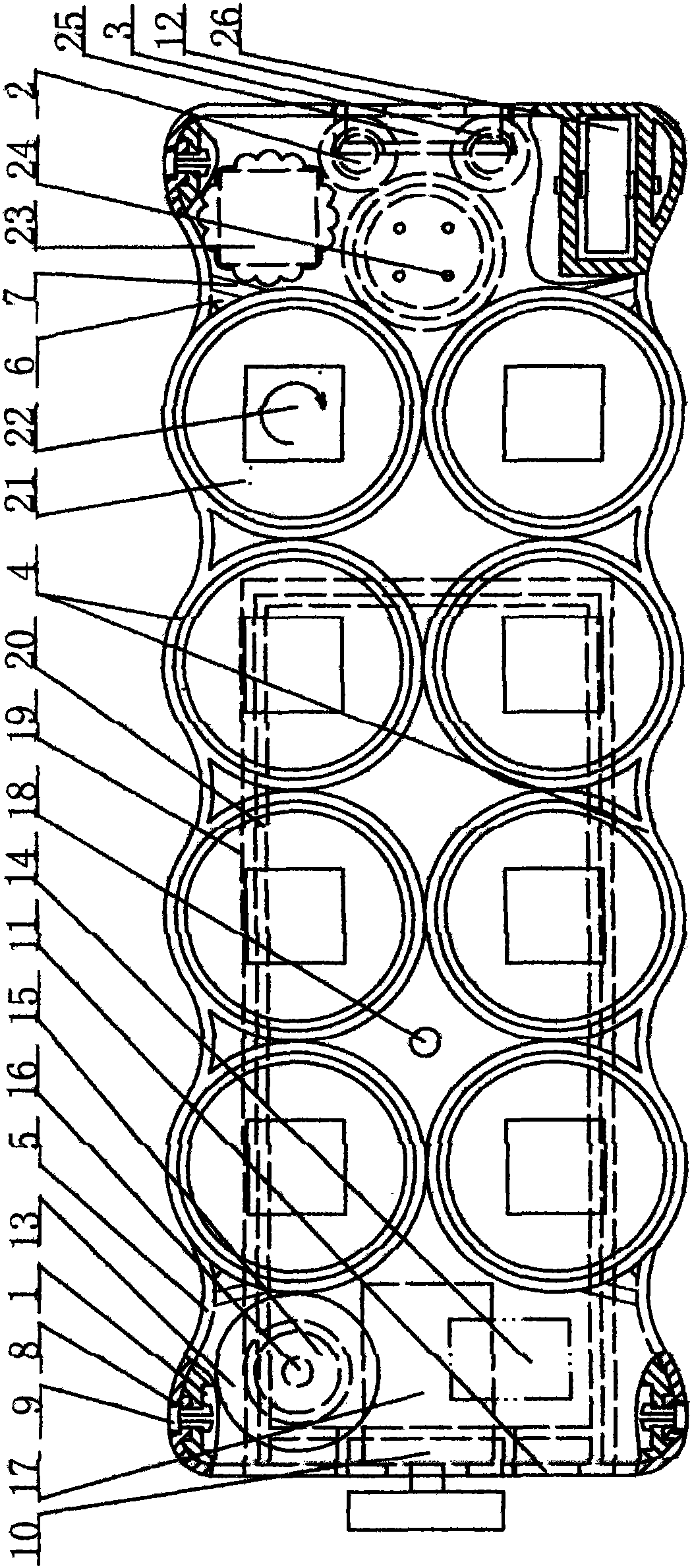

[0023]Embodiment one. Embodiment 1 is the best embodiment of the present invention. The eight filter cartridges are conjoined filter cartridges, the bottom surface of which is connected and fixed with the lower trough base to form a whole. Each filter cartridge is connected in series to each segmented pipeline of the lower base 1 through each water outlet, and connected to the inlet and outlet. A water passage is formed between the inlet and outlet pipe interfaces 2 and 3 of the water pipeline. The front and back of each built-in filter gallbladder are connected to form a filter channel. The both sides of front and rear housing 5,12 contact and cooperate with the cylinder wall of two front and rear end filter cartridges, and continue the both sides corrugated concave-convex housing that double row filter cartridge constitutes. Elastic connector 9 is a load-bearing connector. Front and rear handle structures 10, 25 are set on the front and rear shells of the machine, so that...

Embodiment 2

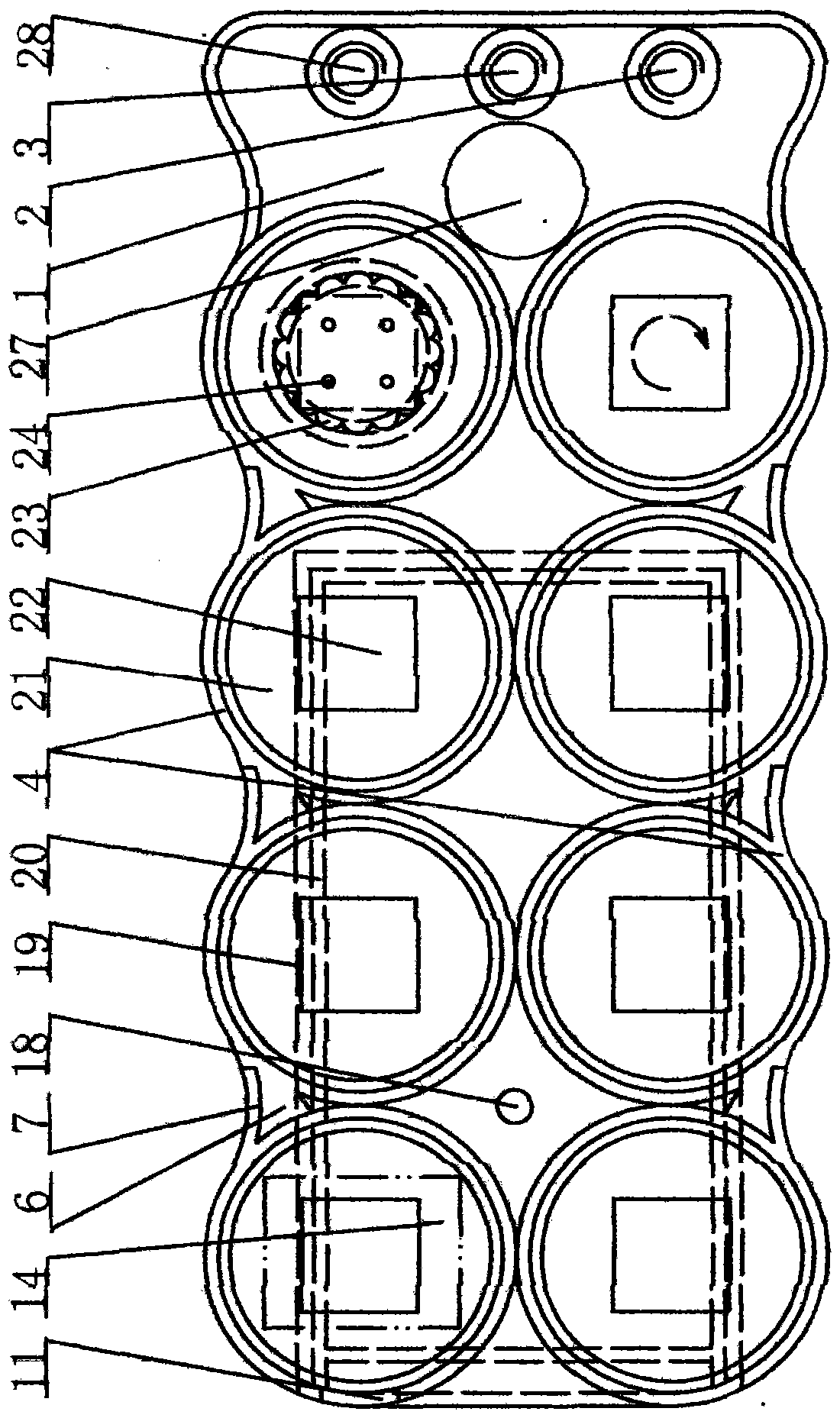

[0043] Example 2. The eight discrete filter cartridges are arranged in two rows, and are inserted vertically in pairs. The bottom surface of the filter cartridges is connected and fixed with the lower grooved machine base to form a one-piece filter cartridge. The front filter cartridge of the display window 11 is set as the equipment warehouse; Each water outlet is connected in series with each section pipeline of the lower machine base 1, and the water inlet and outlet pipeline interfaces 2 and 3 of the water inlet and outlet pipelines are connected to form a water passage. The front and back of each built-in filter gallbladder are connected to form a filter channel.

[0044] When the built-in filter galls connected in series are equipped with three-water port filters with concentrated water outlets, such as ultrafiltration membrane built-in filters, nanofiltration membranes or reverse osmosis membrane filters, the relevant filter cartridges are provided with corresponding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com