Preparation method of cell matrix-free material for porcine adipose tissue

A cell-free matrix and pig fat technology, applied in medical science, prosthesis, etc., can solve the problems of extracellular matrix, expensive enzymes, incomplete decellularization, etc., and achieve good industrial application prospects, good three-dimensional structure, cheap to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

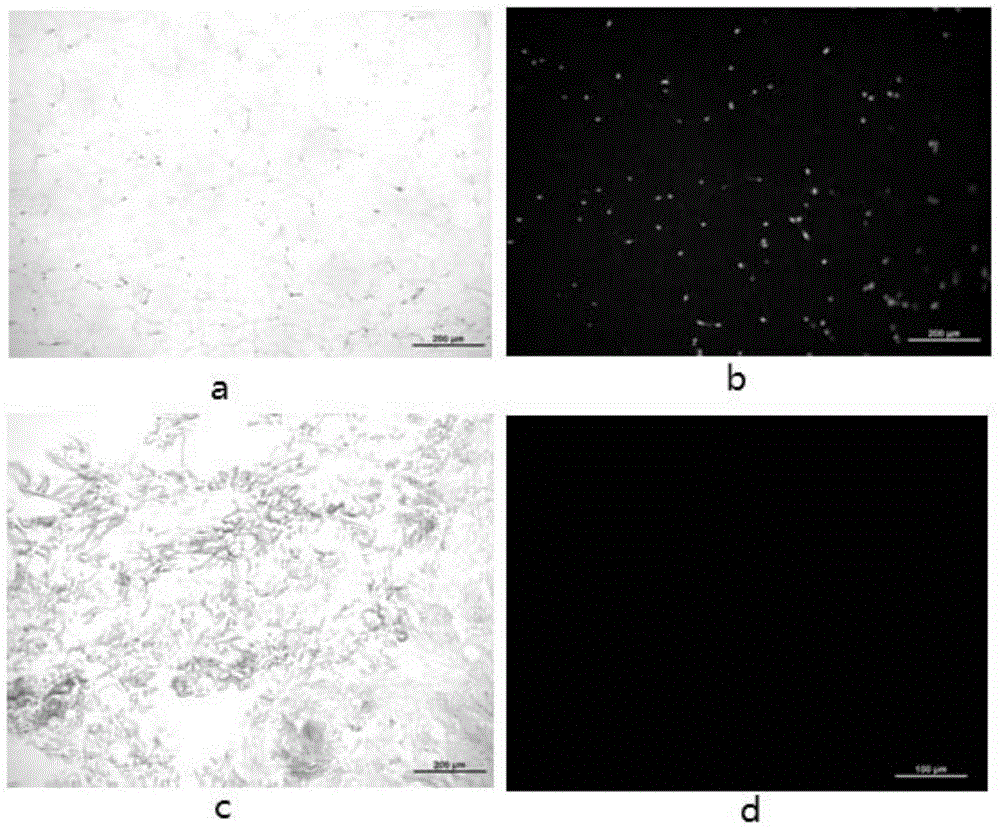

[0047] Example 1 Preparation method of porcine adipose tissue acellular matrix material of the present invention

[0048] 1. Preparation method

[0049] (1) Take fresh subcutaneous fat and rinse it with normal saline to remove blood and other impurities on the fat surface;

[0050](2) Cut the adipose tissue to a size of 1 cm×1 cm×1 cm, and homogenize the adipose tissue and saline at a volume ratio of 1:1 (12000 rpm, 5 min). The solution obtained after homogenization was centrifuged at 3500 rpm for 5 min, and the upper layer of fat was discarded;

[0051] (3) Rinse the lower layer material obtained by centrifugation with PBS solution and then pulverize it with a ball mill (2500r / s, 5min);

[0052] (4) Rinse the powdery material with 0.5% SDS solution at room temperature for 4 hours, rinse with a large amount of PBS solution until there is no foam, and centrifuge (3500rpm, 5min);

[0053] (5) Rinse the powdery material with 100% isopropanol solution for 2 hours to degrease, a...

Embodiment 2

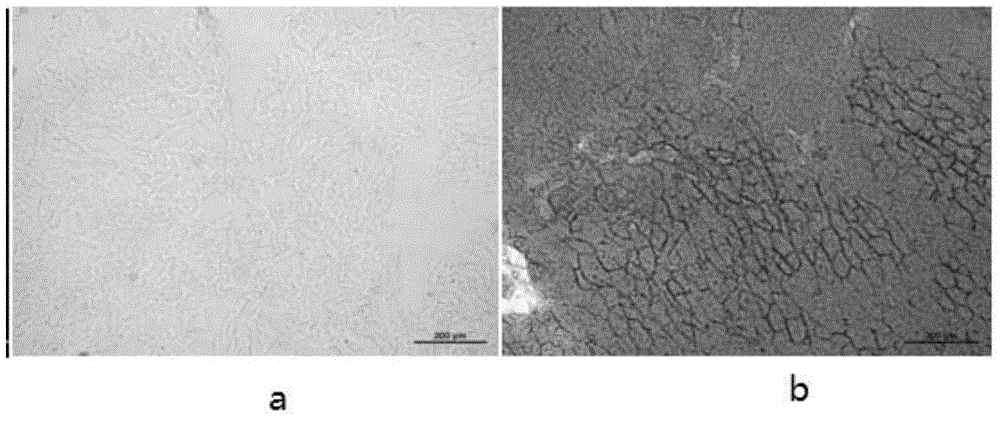

[0055] Example 2 The preparation method of porcine adipose tissue acellular matrix material of the present invention

[0056] 1. Preparation method

[0057] (1) Take fresh subcutaneous fat and rinse it with water to remove blood and other impurities on the surface of the fat;

[0058] (2) Cut the adipose tissue to a size of 0.5cm×0.5cm×0.5cm, and homogenize the adipose tissue and saline at a volume ratio of 1:0.5 (10000rpm, 3min). The solution obtained after homogenization was centrifuged at 3000rpm for 3min, and the upper layer of fat was discarded;

[0059] (3) Rinse the lower layer material obtained by centrifugation with PBS solution, and then pulverize it with a ball mill (2000r / s, 3min);

[0060] (4) Rinse the powdery material with 0.25% SDS solution at room temperature for 2 hours, rinse with a large amount of PBS solution until there is no foam, and centrifuge;

[0061] (5) Rinse the powdery material with 80% isopropanol solution for 1 hour to degrease, and rinse wi...

Embodiment 3

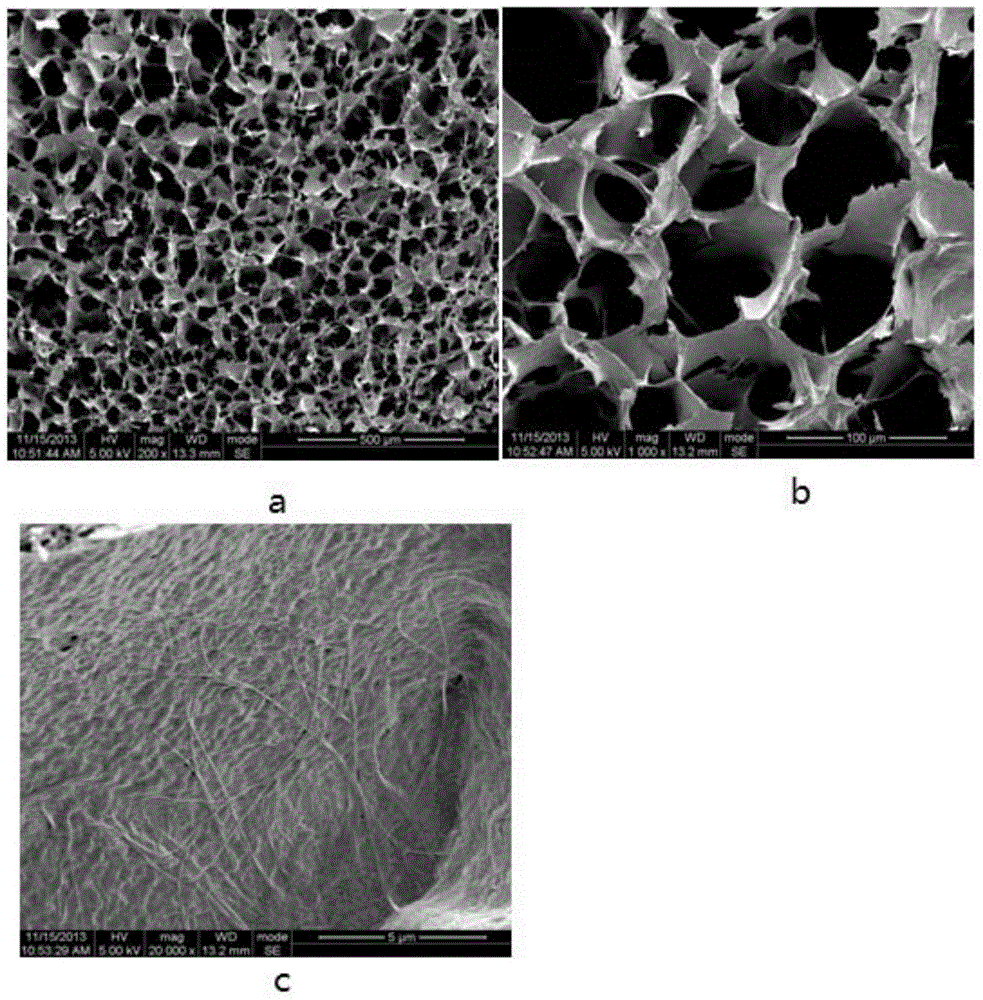

[0063] Example 3 Preparation method of porcine adipose tissue acellular matrix material of the present invention

[0064] 1. Preparation method

[0065] (1) Take fresh subcutaneous fat and rinse it with water to remove blood and other impurities on the surface of the fat;

[0066] (2) Cut the adipose tissue to a size of 1.5cm×1.5cm×1.5cm, and homogenize the adipose tissue and saline at a volume ratio of 1:2 (15000rpm, 7min). The solution obtained after homogenization was centrifuged at 4000 rpm for 7 minutes, and the upper layer of fat was discarded;

[0067] (3) The lower layer material obtained by centrifugation was rinsed with PBS solution and then pulverized with a ball mill (3000r / s, 7min);

[0068] (4) Rinse the powdery material with 1% SDS solution at room temperature for 6 hours, rinse with a large amount of PBS solution until there is no foam, and centrifuge;

[0069] (5) Rinse the powdery material with 100% isopropanol solution for 3 hours to degrease, and rinse w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com