An electric heating plate

A dish warmer and electric heating technology, which is applied in cleaning equipment, household utensils, household items, etc., to achieve the effects of preventing falling, improving heating and evaporation effects, heating uniformity and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

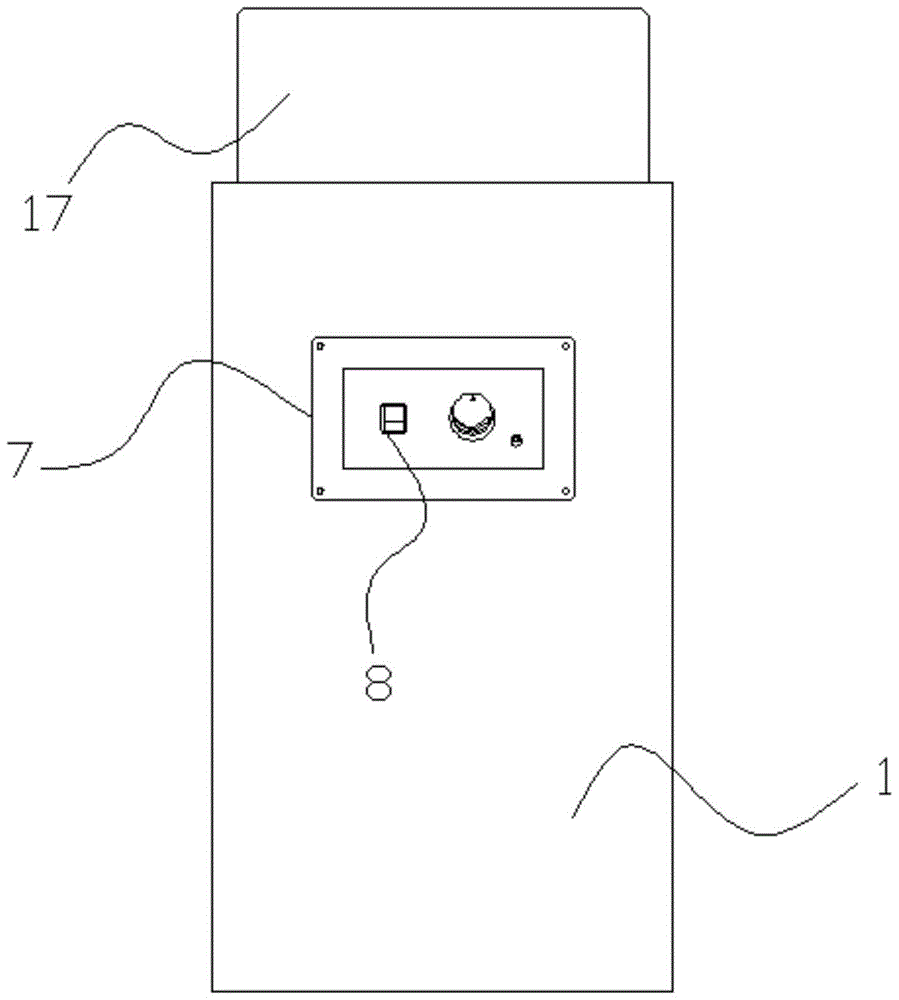

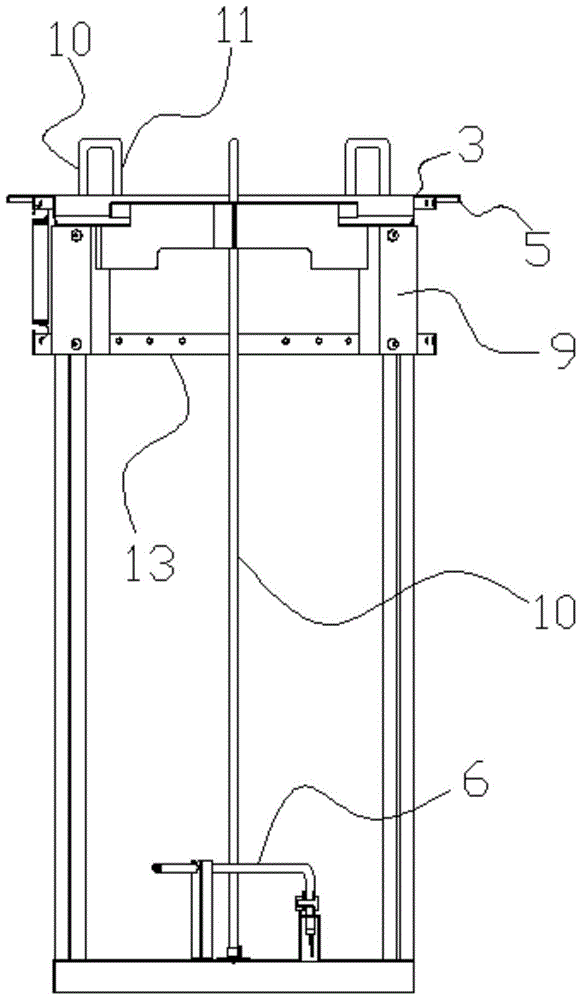

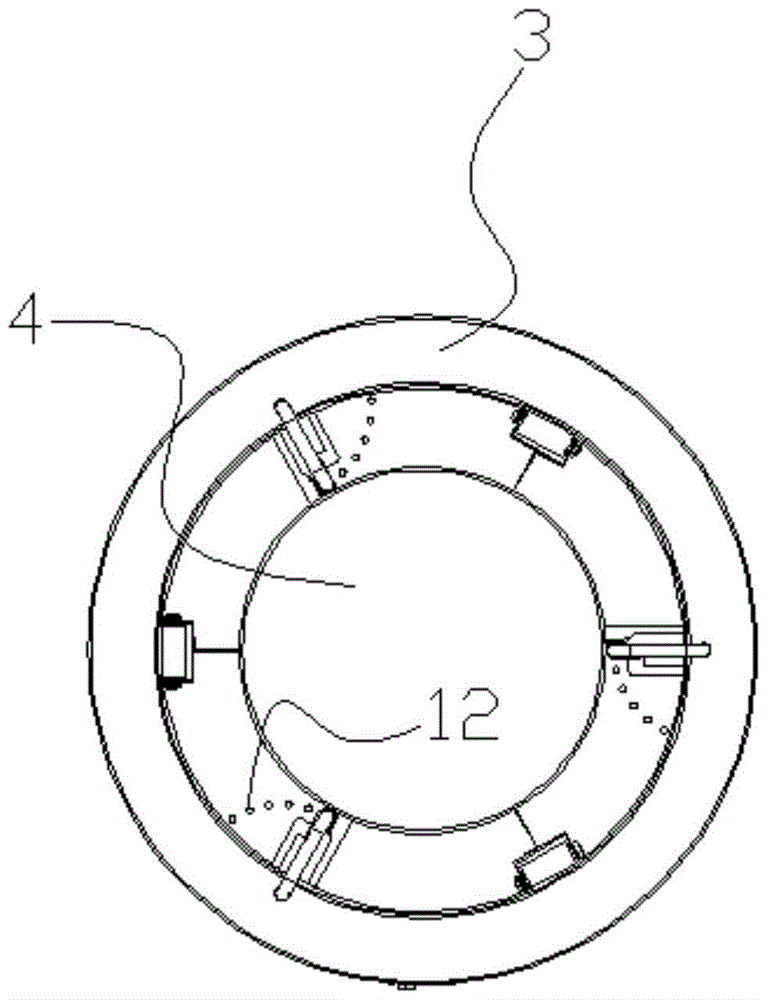

[0025] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the shown embodiment, an electric heating dish warmer includes a body 1, the body has an electric heating chamber 2, and the body is provided with a warming plate seat panel 3 and a dish warming seat tray 4, The plate warming seat panel includes a bottom edge and a plate edge 5 mounted on the top surface of the side wall of the fuselage. The plate warming seat tray is inside the plate warming plate seat and contacts the bottom edge. The electric heater An electric heating tube 6 is arranged in the cavity, a panel box 7 is arranged on the described fuselage, a power switch 8 is arranged on the described panel box, the described electric heating tube is connected on the chassis of the fuselage, and the fuselage A number of base blocks 9 are provided on the base block, and a limit body is provided on the base block. The limit body includes a base rod 10 that can slide up and down relative to th...

Embodiment 2

[0030] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown in , the tray of the warming plate seat is provided with two opposite dial parts. The dial part includes a chute 19 and a bottom slider 20 slidably connected to the chute. One end of the chute There is a locking slot 21 that can be clamped with the bottom slider, and the bottom slider is provided with a sliding column 22 that can rotate relative to the bottom slider. The sliding column is provided with a number of sub-dials 23, Said dial plate includes a horizontally inserted half plate 24 and an inclined dial up swash plate 25, the top surface of said inserted half plate is a dial surface, said dial up swash plate has a dial up slope 26, The dial-up slope is connected to the sub-disc surface, and the highest point of the dial-up slope is provided with a top disc groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com