Quick pulping method of soybean milk machine

A soybean milk machine and pulping technology, which is applied to dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of prolonged pulping cycle, long natural cooling time, and poor effect of air blowing and overflow prevention, etc. The heating time is shortened, the pulping cycle is shortened, and the anti-overflow efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

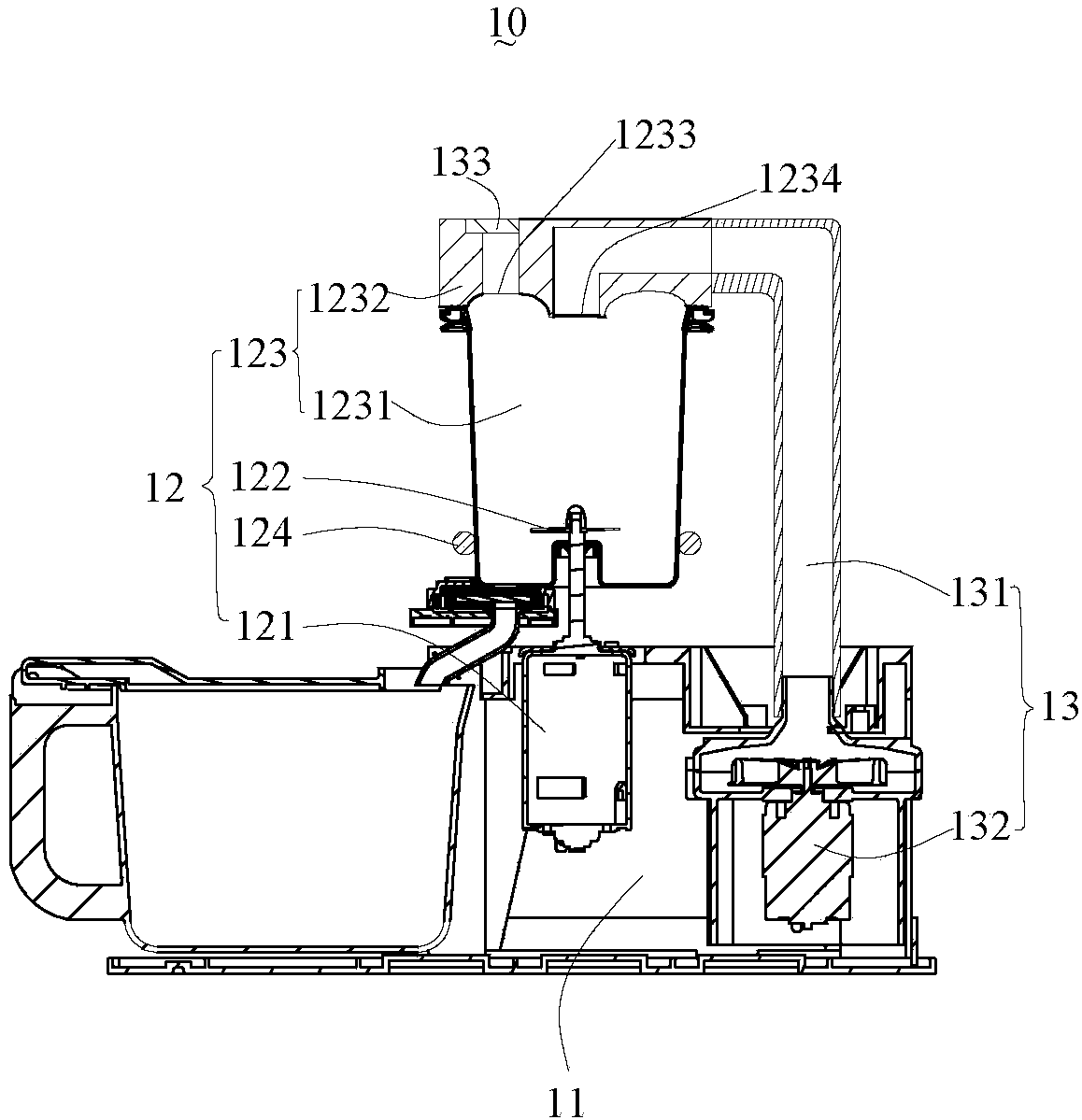

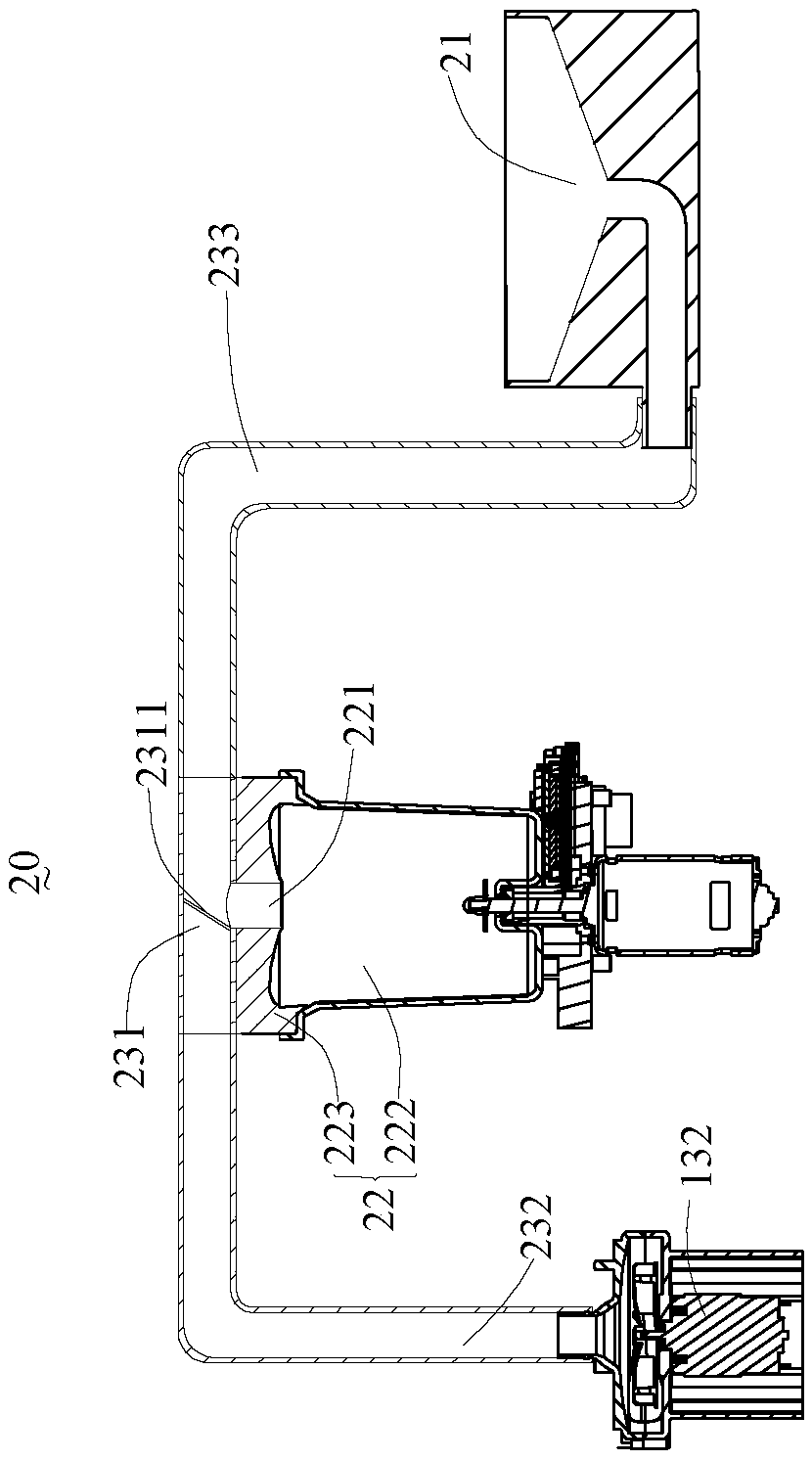

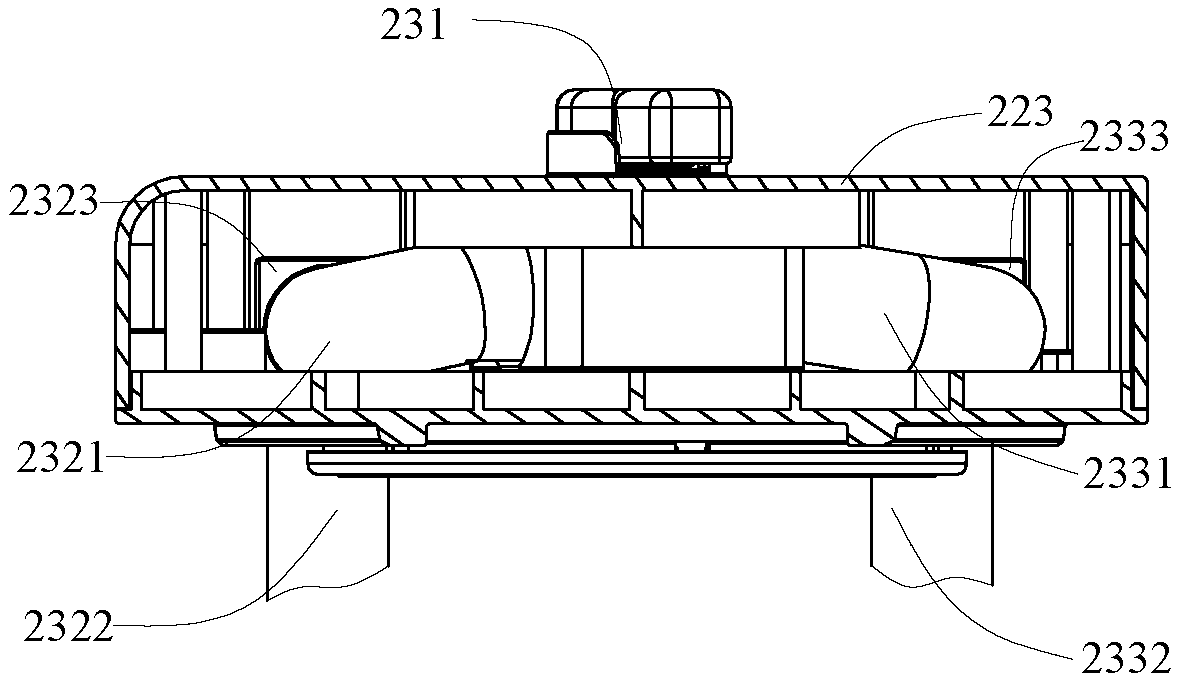

[0037] see figure 1 The soybean milk machine 10 includes a base 11, a pulping assembly 12, an air extraction assembly 13 and a control unit (not shown in the figure), and the pulping assembly 12, the air extraction assembly 13 and the control unit are all arranged on the base 11 .

[0038] The pulping assembly 12 includes a motor 121, a pulverizer 122, a pulverizer 123 and a heating device 124 for heating the pulverizer 121, the motor 121 and the heating device 124 are electrically connected to the control unit, and the motor 121 drives the pulverizer 122 to rotate The pulverizer 123 includes a cylinder body 1231 with an opening and a cylinder head 1232 closing the opening. The pulverizing tool 122 is located in the cylinder body 1231 , and the cylinder head 1232 is provided with an air inlet 1233 and an air outlet 1234 .

[0039] Described exhaust assembly 13 comprises exhaust pipe 131 and air pump 132, and this air inlet 1233 communicates with the outside world, and this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com