Production method of sugar-reducing polysaccharide granules with coprinus comatus

A technology of Coprinus comatus polysaccharides and granules, which is applied in polysaccharide/gum-containing food ingredients, pharmaceutical formulas, and functions of food ingredients. It can solve the problems of cumbersome administration, inconvenient operation, and large body irritation, and achieve stable drug content. , Less hygroscopicity, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

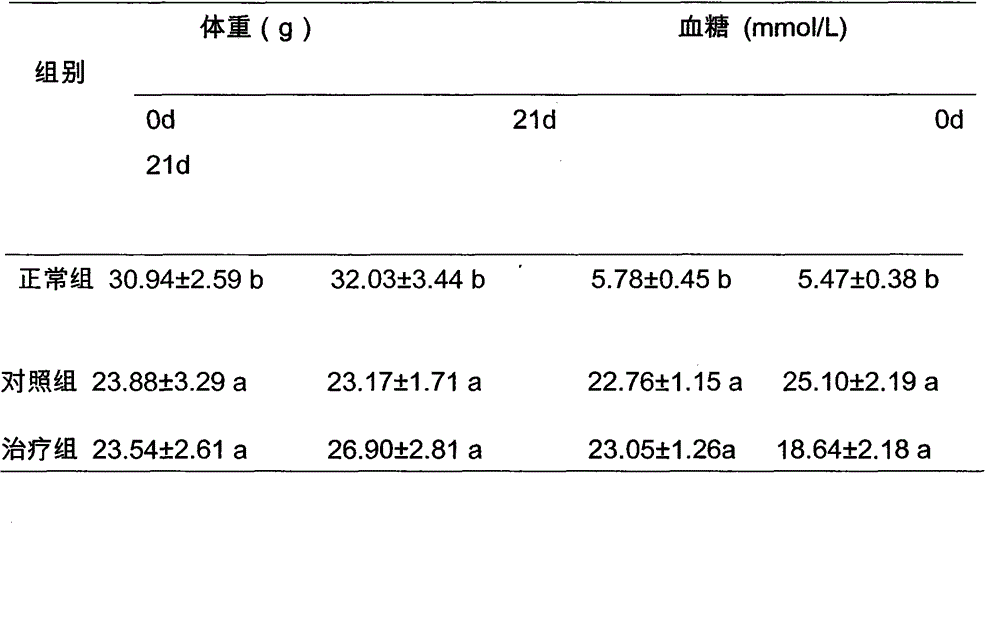

Examples

Embodiment 1

[0025] The preparation of embodiment 1 Coprinus comatus polysaccharide granule

[0026] Prepare as follows:

[0027] (1) Coprinus comatus polysaccharide (purchased from Hangzhou Zhonggu Shannian Biotechnology Co., Ltd., the specification is 10g / bag, the same below), sugar powder (purchased from Tianjin Bodi Chemical Co., Ltd., the specification is 25kg / bag, the same below) , hydroxypropylmethylcellulose (purchased from Anhuishanhe Pharmaceutical Excipients Co., Ltd., the specification is 25kg / bag), etc. are dried and pulverized respectively; Coprinus comatus polysaccharide is passed through a 100-mesh sieve, and sugar powder and hypromellose are passed through a 100-mesh sieve. 80 mesh sieve for standby.

[0028] (2) Put 60g of Coprinus comatus polysaccharide and 720g of powdered sugar in a mixer, then gradually add 360g of hydroxypropyl methylcellulose and 60g of water, and mix well to make soft material; pass the soft material through a 16-mesh sieve to make wet granules ,...

Embodiment 2

[0029] The preparation of embodiment 2 Coprinus comatus polysaccharide granules

[0030] Prepare as follows:

[0031] (1) Coprinus comatus polysaccharide, mannitol (purchased from Henan Huasen Biotechnology Co., Ltd., the specification is 25kg / bag), dextrin (purchased from Shanxi Xiwang Sugar Co., Ltd., the specification is 25kg / bag) etc. are dried separately , crushed; Coprinus comatus polysaccharide passed through a 100-mesh sieve, dextrin and mannitol passed through an 80-mesh sieve for later use;

[0032] (2) Put 50g of Coprinus comatus polysaccharide and 1250g of mannitol in a mixer, gradually add 300g of dextrin and 40g of water, and mix well to make a soft material; pass the material through a 16-mesh sieve to make wet granules, and then drum at 60°C After air-drying, use 20 meshes to granulate, then subpackage, seal, and pack to obtain Coprinus comatus polysaccharide granules.

Embodiment 3

[0033] The preparation of embodiment 3 Coprinus comatus polysaccharide granules

[0034] (1) Coprinus comatus polysaccharide, powdered sugar, povidone K30 (purchased from Xi'an Yuelai Pharmaceutical Technology Co., Ltd., specification: 25kg / barrel) were dried and crushed respectively; Coprinus comatus polysaccharide was passed through a 100-mesh sieve, powdered sugar, poly Pass Vitone K30 through an 80-mesh sieve for later use;

[0035] (2) Put 30g of Coprinus comatus polysaccharide and 420g of powdered sugar in a mixer, gradually add 120g of povidone K30 and 30g of water, and mix well to make a soft material; pass the soft material through a 16-mesh sieve to make wet granules, and then 60°C After blasting and drying, granulate with 20 meshes, then subpackage, seal and pack to obtain Coprinus comatus polysaccharide granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com