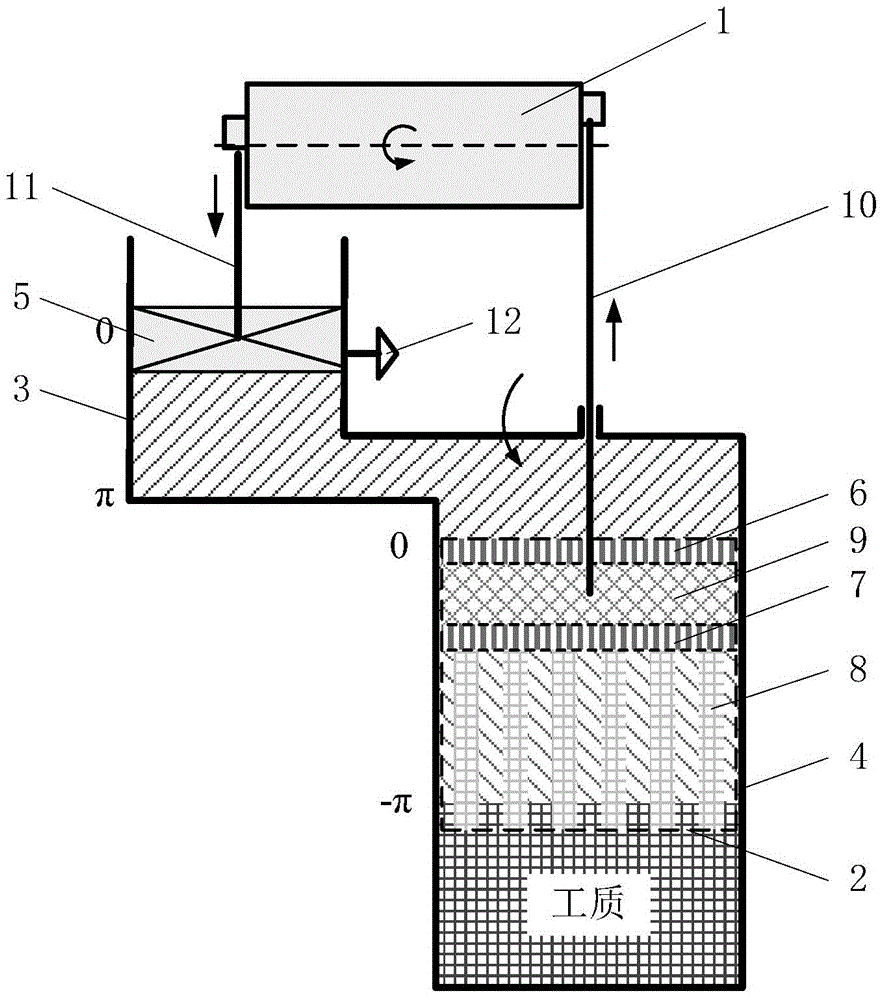

Stirling thermoelectric generation mechanism

A technology of thermoelectric power generation and power cylinder, applied in the directions of generators/motors, electrical components, etc., can solve the problems of complex system structure and high cost, and achieve the effects of low requirements, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The temperature of the working fluid in the liquid storage distribution cylinder (4) can be higher or lower than the ambient temperature, and the phase change of the working fluid can occur or not.

[0032] 1. When the temperature of the working fluid is lower than the ambient temperature

[0033] The phase of the power piston (5) is ahead of the gas distribution piston (2).

[0034] When the power piston (5) moves downward, the pressure of the power cylinder (3) rises, and the gas enters the upper chamber of the liquid storage distribution cylinder (4), and at the same time the gas distribution piston (2) moves upward, and the gas in the upper chamber of the distribution cylinder (4) Through the small axial holes distributed on the heat shield (6), regenerator (9) and heat shield (7), it enters the lower chamber of the cylinder (4). When the gas passes through the regenerator (9), the cold storage medium built in the regenerator (9) cools the gas through heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com