A liquid heat engine and power output device

A heating device and liquid technology, applied in the field of power machinery, can solve the problems of rapid damage to the casing and transmission parts, high requirements for heat medium, poor thermal conductivity of gas, etc., and achieves low reciprocating working frequency of pistons, low heat medium requirements, and temperature difference. require small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

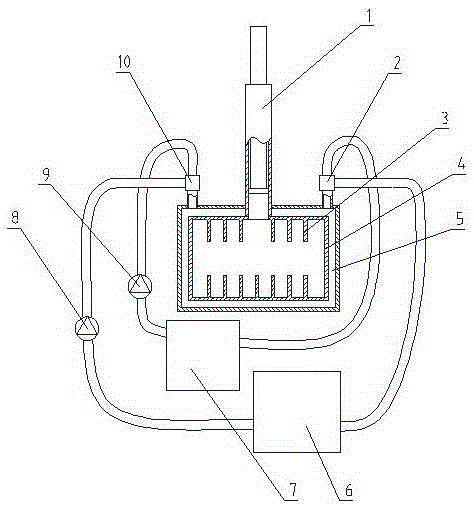

[0019] Such as figure 1 The liquid heat engine shown includes an expansion tank 4 and a single-acting hydraulic cylinder 1. The expansion tank 4 is provided with a heat-expanding liquid working fluid. The hydraulic chamber of the hydraulic cylinder 1 communicates with the inside of the expansion tank 4. Cooling device, as can be seen from the figure, the structure of the working medium heater and the working medium cooler is: a heat exchange chamber 5 is provided on the side wall of the expansion tank, and a heat exchange inlet and a heat exchange outlet are provided on the heat exchange chamber 5. The heat exchange inlet is connected to the heat pump 9 and the cooling pump 8 through the three-way valve 10, the heat pump 9 is connected to the heat source 7, the cooling pump 8 is connected to the cold source 6, and the heat exchange outlet is connected to the heat source 7 and the cold source 6 through the three-way valve 2 connected. The inner wall of the expansion tank 4 is ...

Embodiment 2

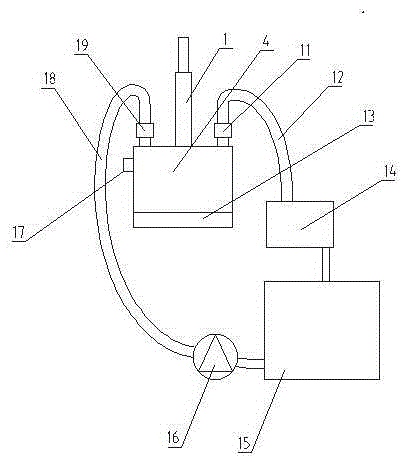

[0022] Such as figure 2 The liquid heat engine shown is characterized in that it includes an expansion tank 4 and a single-acting hydraulic cylinder 1. The expansion tank 4 is provided with a heat-expanding liquid working medium, and the hydraulic cavity of the hydraulic cylinder 1 is connected to the expansion tank 4. A working medium heating device and Working fluid cooling device, from figure 2 It can be seen from the figure that the working medium heating device is provided with a heater 13 at the bottom of the expansion tank, or it can be a heater surrounding the outside of the expansion tank or a heater placed inside the expansion tank, which can quickly heat the liquid working medium. The working fluid cooling device is: a cold liquid tank 15 is provided, and the expansion tank 4 is provided with a liquid inlet and a liquid discharge port. A liquid inlet valve 19 is provided on the liquid port; the liquid discharge port is connected with the cold liquid tank 15 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com