Paddle type sludge drying machine performance judgment method

A technology for sludge drying and judging methods, which is applied to the testing of machines/structural components, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

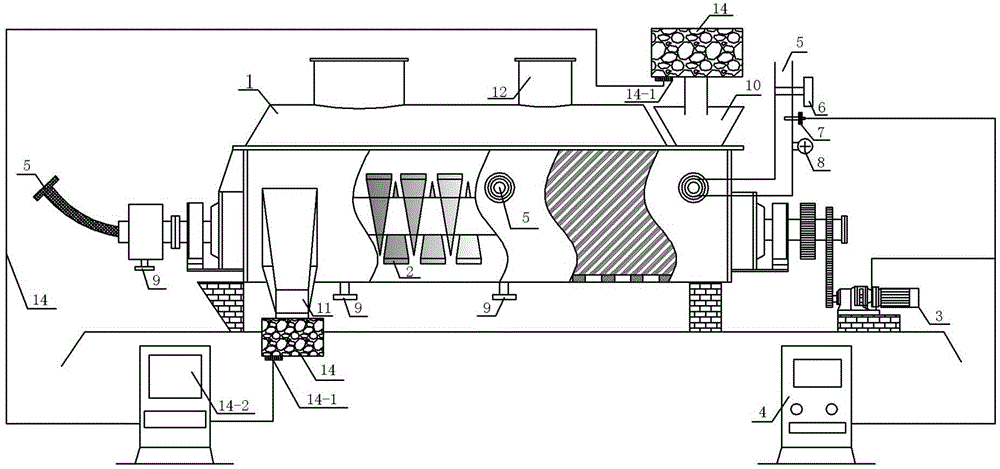

[0048] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0049] The invention provides a method for judging the performance of a paddle-type sludge dryer. The paddle-type sludge dryer usually uses steam or heated heat-conducting oil as the drying medium, and uses indirect heating, supplemented by paddle stirring, wherein There are hollow and solid blade designs. In this embodiment, the hollow paddle type sludge dryer to be determined is used to dry the sludge. Assuming that the dryer uses steam as the drying heat source, the structure of the sludge dryer in this embodiment is as follows figure 1 As shown, the sludge dryer performance determination test system in this embodiment includes a paddle-type sludge dryer and an auxiliary measurement system.

[0050] Such as figure 1 As shown, the sludge dryer consists of a casing 1, two paddle-type hollow paddle shafts 2, a driving device 3 and a control cabinet 4. The superheated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com