One-stop flushing and pressure testing method of hydraulic system of self-elevating drilling platform

A hydraulic system and drilling platform technology, which is applied in the field of one-stop flushing and pressure testing of the jack-up drilling platform hydraulic system, can solve problems such as undiscovered, and achieve the effects of improving cleanliness, shortening the working cycle, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

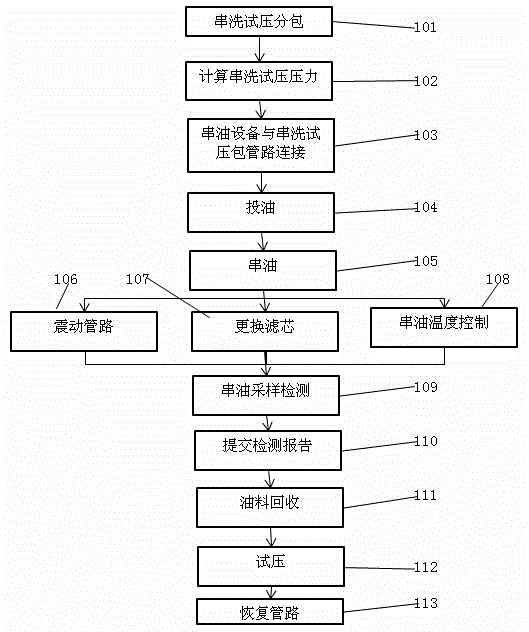

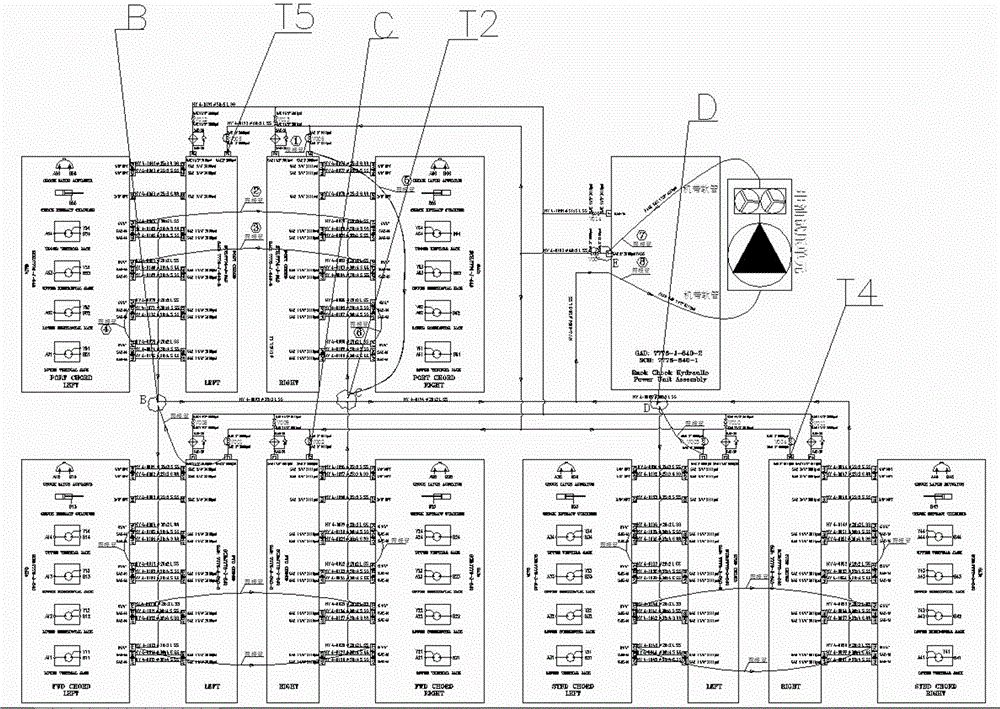

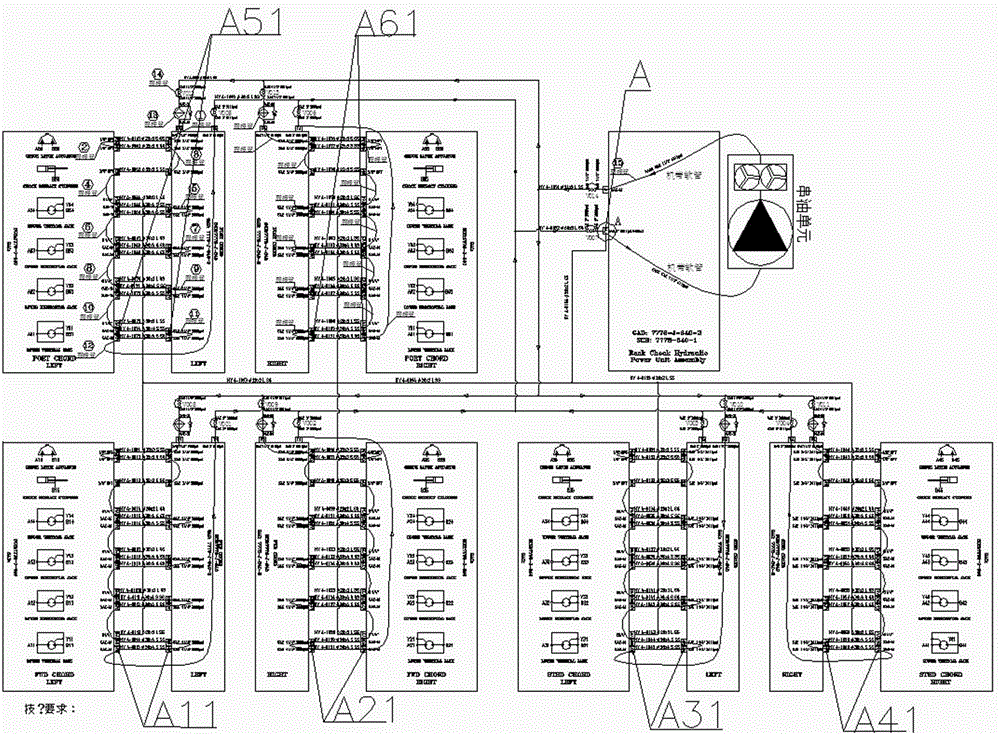

[0034] Such as figure 1 As shown, the present invention discloses a one-stop flushing and pressure testing method for the hydraulic system of a self-elevating drilling platform. The method is to use a dual-purpose oil stringing device to flush the hydraulic system with oil, and after flushing, start the pressure test pump to complete the hydraulic system. The pressure test work, in which the dual-purpose oil stringing equipment is Algate FTE-800 equipment for flushing and dual-purpose;

[0035] The specific steps of flushing pressure test method are as follows:

[0036] (1) Subcontracting for string washing and pressure testing: Firstly, the string washing and pressure testing packages are divided, and the subcontracting meets the conditions for simultaneous string washing and pressure testing.

[0037] (2) Calculate the pressure test pressure of series washing: after the subcontracting is completed, calculate the flow rate, viscosity, working pressure and temperature of the ...

Embodiment 2

[0064] In this example, on the basis of Example 1, in order to improve the flushing efficiency of the series oil pressure test bag A and the oil series pressure test bag B, the filtration precision of the special fine oil filter trolley for the pressure test in step (4) is 10 μm, Step (8) The temperature of the string oil is kept at 60°C-65°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com