Shock wave collision dual-supercharging-type wave pressure supercharger

A gas wave supercharger and shock wave technology, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of insufficient applicability, difficult gas separation, insufficient boost pressure ratio, etc. The effect of significant temperature effect and enhanced supercharging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

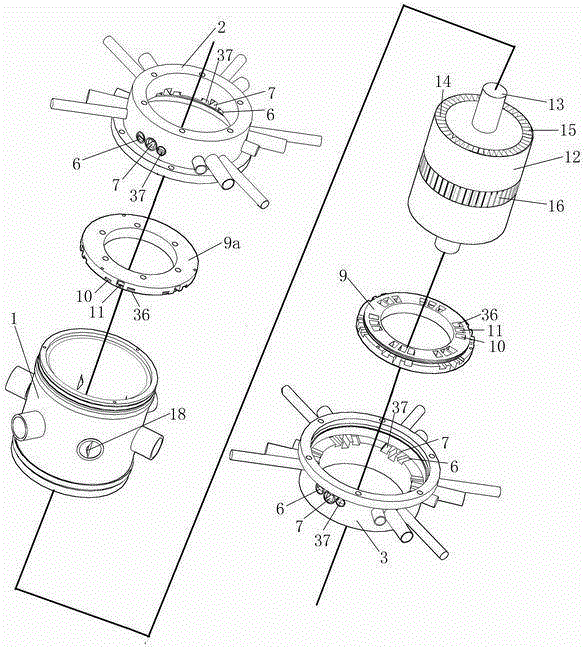

[0022] Example 1 High-pressure gas-driven shock wave collision double pressurized gas wave supercharger

[0023] figure 1 , 2 A high-pressure gas-driven shock-impinging double-pressurized gas-wave supercharger is shown. The core is to use the double pressurization mechanism of shock wave and transmission shock wave to realize the high pressure ratio pressurization of the compressed gas, which is mainly composed of three parts: the main body, the upper body and the lower body. The main body includes a main body shell 1 and a drum 12 with a shock wave collision tube 14 evenly arranged in the circumferential direction. The shock wave collision tube 14 is fan-shaped in cross section, and has a square through hole 16 at a symmetrical position in the middle; the main body There are isosceles trapezoidal pressurized fluid outlets 18 uniformly distributed in the circumferential direction at the symmetrical position in the middle of the housing shell 1. The position of the square ...

Embodiment 2

[0026] Example 2 High-pressure saturated water flash drive shock wave collision double pressurized gas wave supercharger

[0027] figure 1 , 2 A high-pressure saturated water flash-driven shock wave collision double pressurized air wave supercharger is shown. The core is to use the double pressurization mechanism of the shock wave and the transmission shock wave to realize the high pressure ratio pressurization of the compressed steam. And the condensation phenomenon in the process of water vapor supercharging is used to realize the separation of high and low pressure fluids, which is mainly composed of three parts: the main body, the upper body and the lower body. The main body includes a main body shell 1 and a drum 12 with a shock wave collision tube 14 evenly arranged in the circumferential direction. The shock wave collision tube 14 is fan-shaped in cross section, and has a square through hole 16 at a symmetrical position in the middle; the main body There are isosceles...

Embodiment 3

[0030] Example 3 Structure-adjustable shock wave collision double pressurized air wave supercharger

[0031] figure 2 The high-pressure driving fluid nozzle 10, the low-pressure expansion fluid nozzle 11 and the low-pressure driven fluid nozzle 36 on the detachable nozzle distribution plate 9 of an adjustable shock wave collision double pressurized air wave supercharger are shown, and the upper body The shell, the high-pressure driving fluid inlet 6 on the lower body shell, the low-pressure expansion fluid outlet 7, the low-pressure driven fluid inlet 37 and the isosceles trapezoidal pressurized fluid outlet 18 on the main body shell 1 and the double-ended looper flange 5 relative to each other. Positional relationship. There are specific angles between the high-pressure driving fluid nozzle 10, the low-pressure expansion fluid nozzle 11 and the low-pressure driven fluid nozzle 36 in the first detachable nozzle distribution plate 9, which are related to different working con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com