Wet-process discharge type ore pulp electrolytic lead device

A technology of slurry electrolysis and wet process, which is applied in the direction of photographic process, instrument, and photographic auxiliary process, etc., can solve the problems affecting the application and development of lead electrolysis of slurry, and achieve the effect of easy implementation, simple and reasonable system structure, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

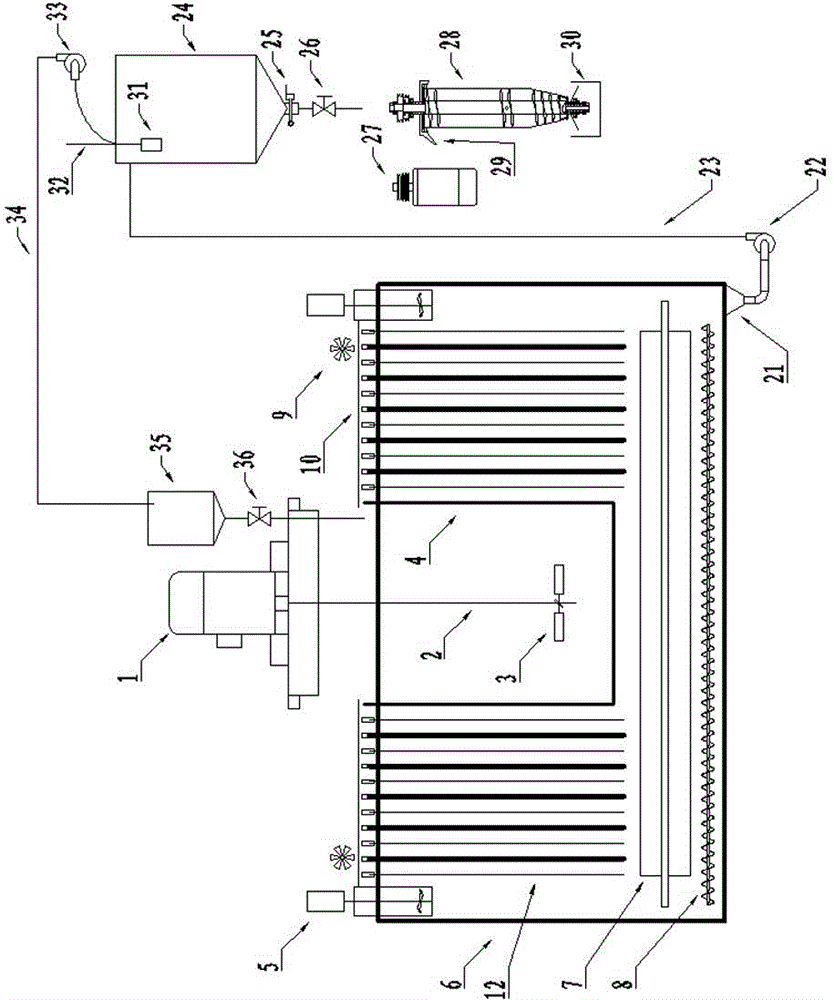

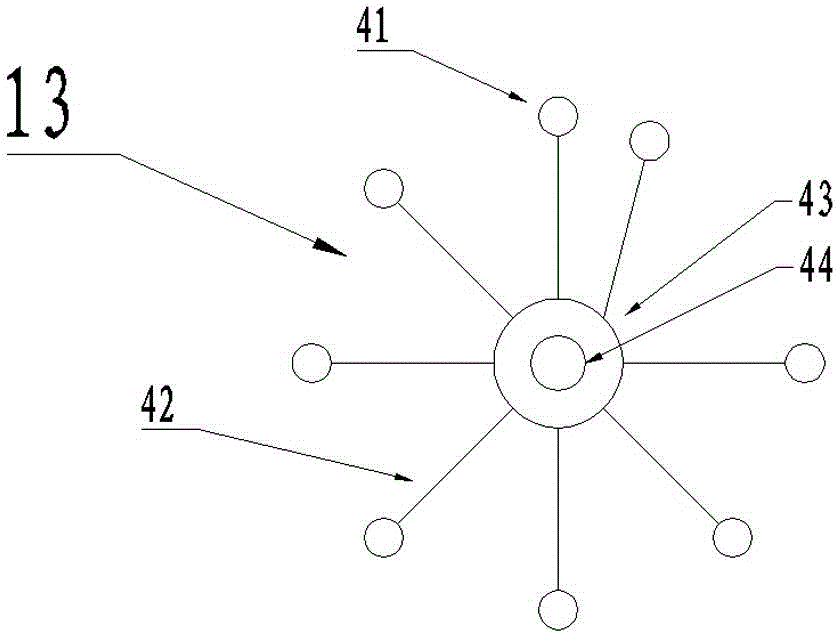

[0031] Such as figure 1 , figure 2 and image 3 The wet discharge type pulp electrolytic lead device shown in the figure includes an electrolytic tank body 6, a common copper bar 11 and an electrolytic plate 12. The electrolytic tank body 6 is provided with an electrolytic diaphragm 4 for placing the pulp, and the electrolytic diaphragm 4 cavity is equipped with a There is a stirring device; the cavity of the electrolytic diaphragm 4 is connected with the electrolytic cell box 6 by an axial flow pump 5 and a pipeline 10; the electrolytic cell box 6 is a structure with a cone bottom 14, and the cone bottom 14 is equipped with an axial stirring paddle 7 and a screw conveyor 8. There is a knocker 13 outside the cone bottom. The knocker is composed of a rubber ball 41, a rope 42, a drum 43 and a rotating shaft 44. The drum 43 is connected to the elastic rubber ball 41 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com