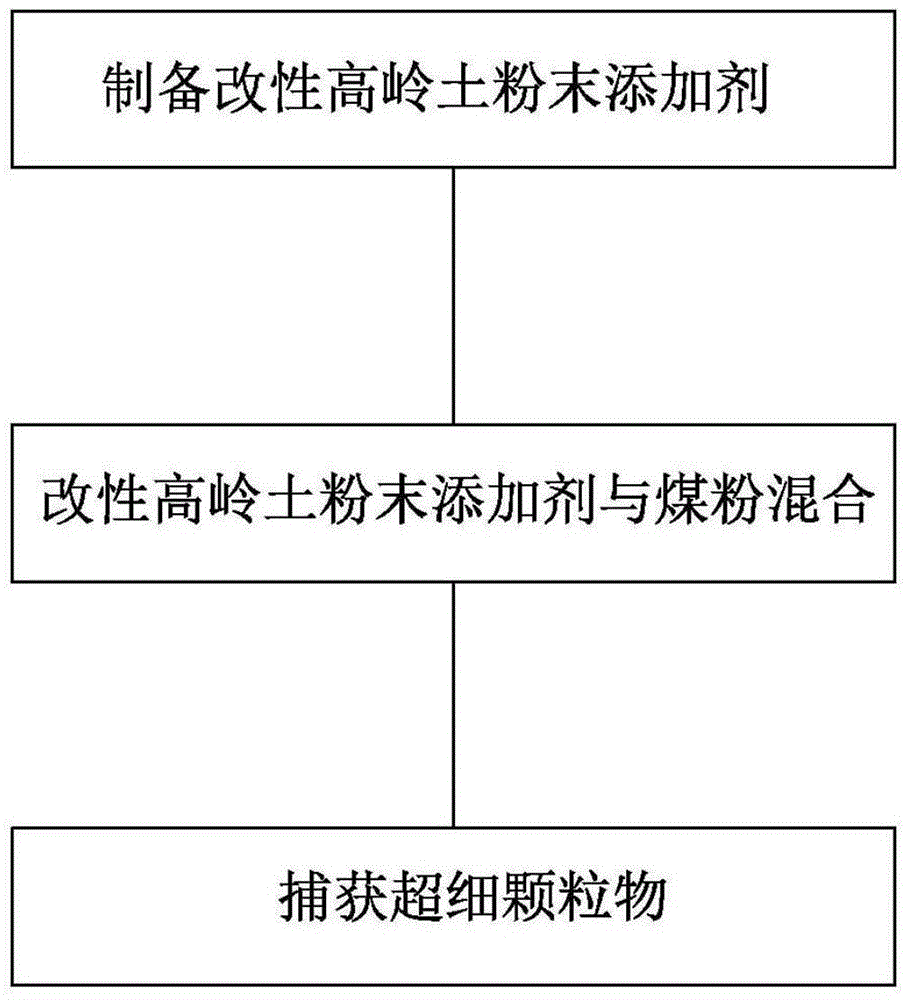

Control method for coal-fired ultra fine particles based on modified kaolin

A technology of ultra-fine particles and control methods, applied in separation methods, chemical instruments and methods, fuels, etc., can solve the problems of large environmental pollution and low adsorption rate, and achieve convenient storage and transportation, stable component functions, and convenient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of hydrochloric acid modified kaolin powder Ⅰ:

[0067] 1) Calcining kaolin at 800°C for 2 hours;

[0068] 2) Add 1 g of kaolin per 7 mL of hydrochloric acid solution, add calcined kaolin to 4 mol / L hydrochloric acid solution, react for 3.5 hours in a constant temperature water bath at 80°C, and then perform centrifugation. Washing and separating to remove chloride ions to obtain hydrochloric acid modified kaolin;

[0069] 3) drying the hydrochloric acid modified kaolin at 80°C;

[0070] 4) After the dried hydrochloric acid modified kaolin is crushed and ground, it is screened with a 100-mesh sieve, and the powder passing through the sieve is collected to obtain hydrochloric acid modified kaolin powder.

[0071] According to the weight ratio of hydrochloric acid modified kaolin powder I to coal powder is 3:100, fully mix hydrochloric acid modified kaolin powder I and coal powder (particle size range 45-100 μm); mix hydrochloric acid modified kaolin powder ...

Embodiment 2

[0073] Preparation of hydrochloric acid modified kaolin powder II:

[0074] 1) Calcining kaolin at 950°C for 2 to 4 hours;

[0075] 2) Add 1 g of kaolin per 10 mL of hydrochloric acid solution, add the calcined kaolin to 3 mol / L hydrochloric acid solution, react for 2 hours in a constant temperature water bath with a temperature of 100 ° C, and perform centrifugation. Separating and removing chloride ions to obtain hydrochloric acid modified kaolin;

[0076] 3) drying the hydrochloric acid modified kaolin at 120°C;

[0077] 4) After the dried hydrochloric acid modified kaolin is crushed and ground, it is screened with a 300-mesh sieve, and the powder passing through the sieve is collected to obtain hydrochloric acid modified kaolin powder.

[0078] According to the weight ratio of hydrochloric acid modified kaolin powder II and coal powder of 4:100, fully mix hydrochloric acid modified kaolin powder II and coal powder (particle size range 45-100 μm); mix hydrochloric acid mo...

Embodiment 3

[0080] Preparation of hydrochloric acid modified kaolin powder III:

[0081] 1) Calcining kaolin at 1000°C for 4 hours;

[0082] 2) Add 1 g of kaolin per 9 mL of hydrochloric acid solution, add calcined kaolin to 5 mol / L hydrochloric acid solution, react for 4 hours in a constant temperature water bath at a temperature of 75 ° C, and then perform centrifugation. After several times of centrifugal washing Separating and removing chloride ions to obtain hydrochloric acid modified kaolin;

[0083] 3) drying the hydrochloric acid modified kaolin at 110°C;

[0084] 4) After the dried hydrochloric acid-modified kaolin is crushed and ground, it is screened with a 200-mesh sieve, and the powder passing through the sieve is collected to obtain hydrochloric acid-modified kaolin powder.

[0085]According to the ratio of hydrochloric acid modified kaolin powder III to coal powder weight ratio of 5:100, hydrochloric acid modified kaolin powder III and coal powder (particle size range 45-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com