Low-carbon mixed alcohol separation system and separation method

A low-carbon mixed alcohol and membrane separation technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, preparation of hydroxyl compounds, etc., can solve problems such as poor separation effect of low-carbon mixed alcohols, and achieve high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

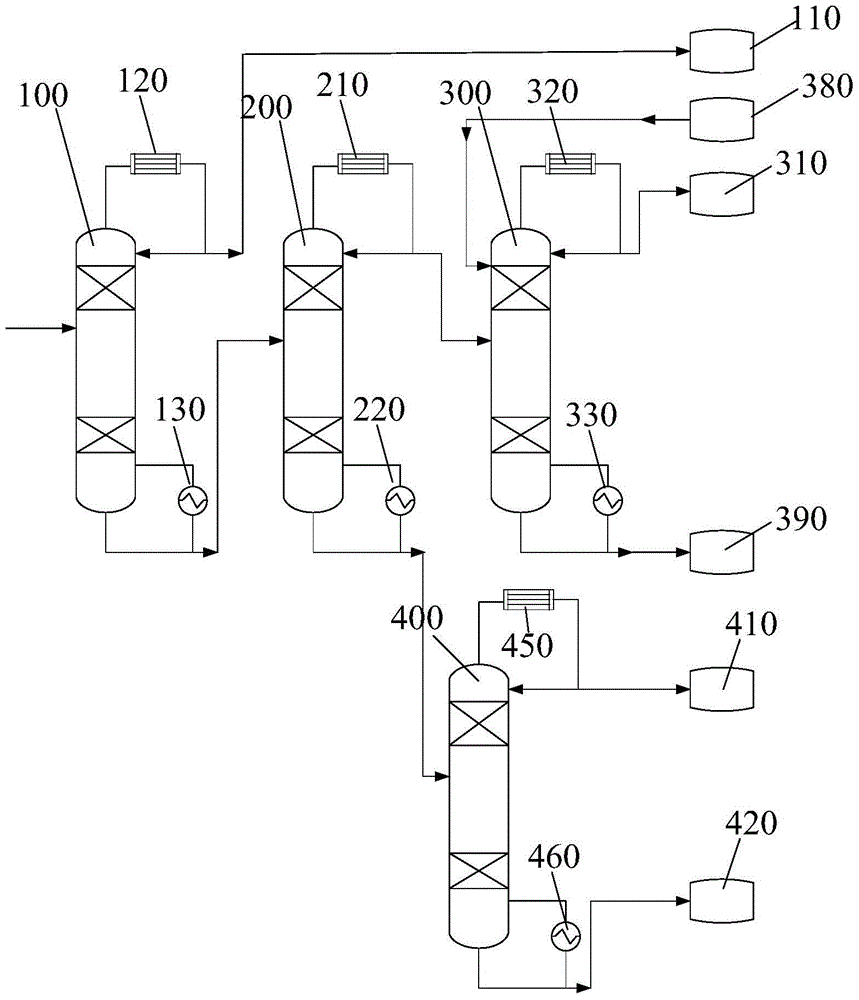

[0067] Low-carbon mixed alcohol separation system is used to separate low-carbon mixed alcohols. The separation system is as follows: image 3 shown.

[0068] The separation system includes: flash tank, non-condensable gas removal tower, first dehydration rectification tower, methanol rectification tower, ethanol rectification tower, extractive rectification tower, n-propanol rectification tower, first phase separator and corresponding cooler.

[0069] The operating conditions of each tower are as follows:

[0070] The operating pressure of the non-condensable gas removal tower is 0.203Mpa(G), and the operating temperature is 112.4°C.

[0071] The operating pressure of the first dehydration rectification tower is 0.081Mpa(G), and the operating temperature is 117.9°C;

[0072] The operating pressure of the methanol rectification tower is -0.05Mpa(G), and the operating temperature is 67.8°C;

[0073] The operating pressure of the ethanol rectification tower is 0.101Mpa(G), a...

Embodiment 2

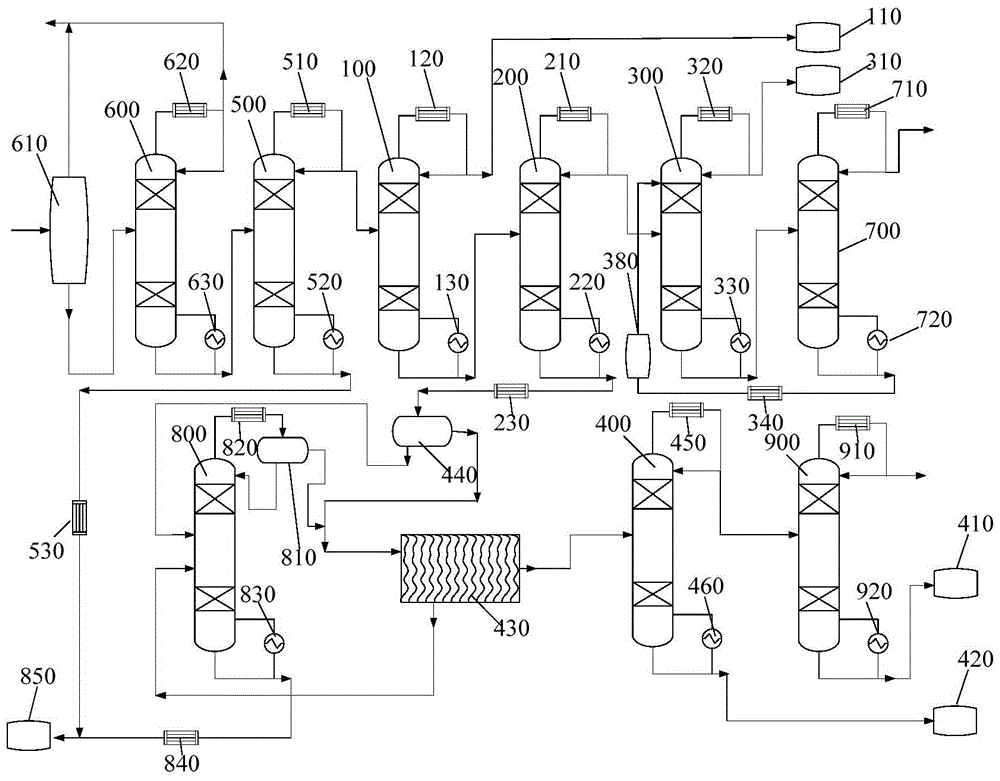

[0078] Use the low-carbon mixed alcohol separation system to separate low-carbon mixed alcohols.

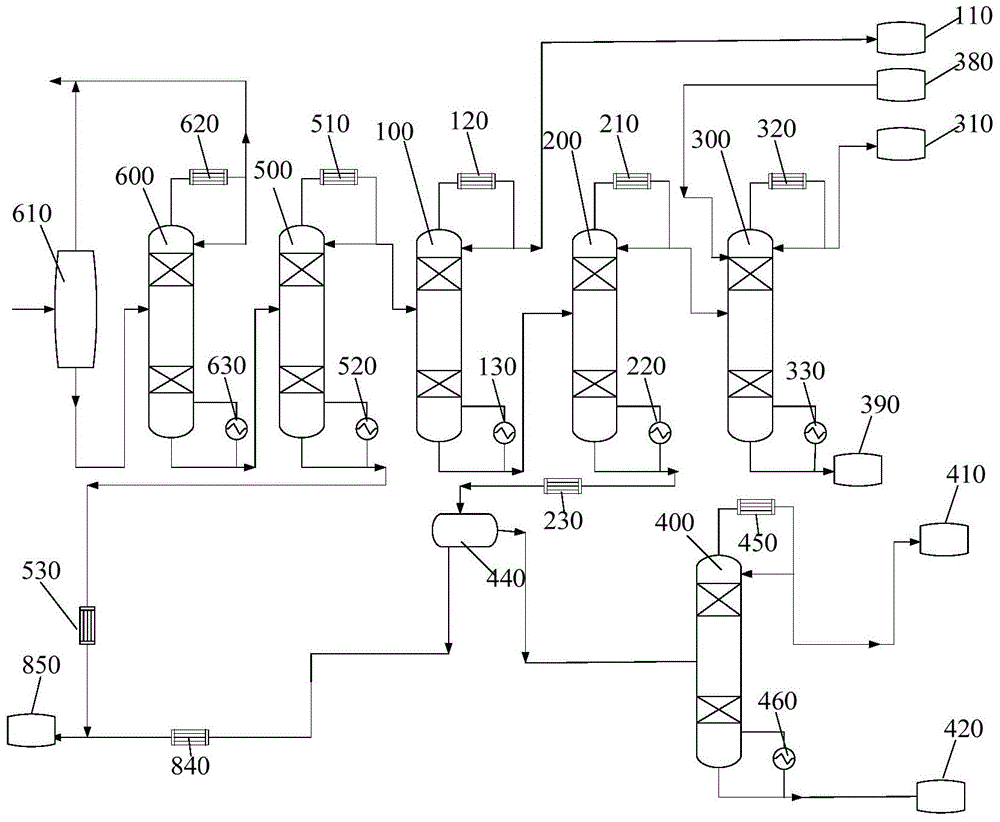

[0079] The separation system includes: methanol rectification tower, ethanol rectification tower, extractive rectification tower, n-propanol rectification tower, extractant recovery tower, n-propanol purification rectification tower, first dehydration rectification tower, second dehydration rectification tower Distillation tower and non-condensable gas removal tower; also includes first phase separator, second phase separator, membrane separation device and corresponding cooler. The extractant is ethylene glycol, and the oil-water separation membrane in the membrane separation device is a ceramic pervaporation membrane.

[0080] The operating conditions of each tower are as follows:

[0081] The operating pressure of the methanol rectification tower is -0.05Mpa(G), and the operating temperature is 67.8°C;

[0082] The operating pressure of the ethanol rectification tower is 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com