Non-pressure infiltration preparation process of functionally graded piezoelectric material (FGPM)

A piezoelectric material and functionally gradient technology, which is applied in the field of preparation of metal-based ceramic functionally gradient piezoelectric materials, can solve the problems of thin-walled parts being easily fractured, increasing production costs, and making small shapes, achieving excellent thermodynamic properties, Short time, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

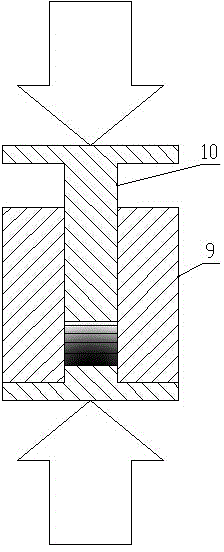

[0038] A pressureless impregnation preparation process for functionally graded piezoelectric materials of the present invention comprises the following steps:

[0039] 1) Raw material preparation: raw materials include vacuum-encapsulated Fe powder, PZT-5 powder and binder (PVA17-88 powder), and the particle size of Fe powder is 7 ; The particle size of PZT-5 powder is 2.5 , 6.5 、15 and 44 , the particle size of the binder is 10 PVA17-88;

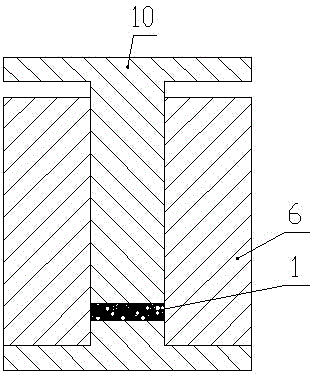

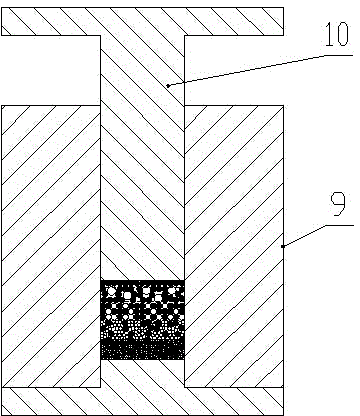

[0040] 2) Preform molding: Mix the above-mentioned PZT-5 powder, Fe powder and PVA17-88 powder in the Etelux Lab2000 glove box according to the volume ratio, and then lay five layers in the steel mold from bottom to top, the first layer 1. The second layer 2, the third layer 3 and the fourth layer 4 are all mixed powders of PZT-5 powder, Fe powder and PVA17-88 powder, and the fifth layer 5 only has Fe powder. The specific ratio of raw materials in each layer and The thickness is shown in Table 1,

[0041] Table 1. Specific rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com