Wheel axle overhauling system

A wheel shaft and wheel set technology, applied in the field of wheel shaft maintenance system, can solve the problems of large workshop floor space, production chaos, occupation, etc., and achieve the effect of high degree of automation, small footprint and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

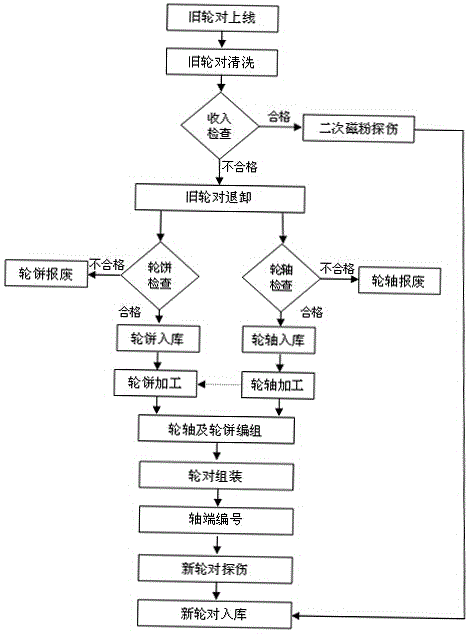

[0016] Axle overhaul methods, including

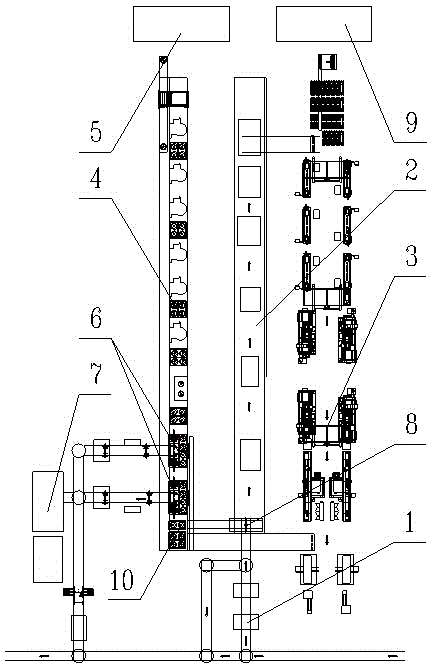

[0017] 1) Before the overhaul of the axle maintenance workshop, a steel platform is built on the upper part of the axle inspection conveying line 2, the axle processing conveying line 3, and the wheel cake processing conveying line 4, and is partitioned according to the workshop plan, and each partition is arranged according to the specified information;

[0018] 2) Install the supporting seat of the axle or wheel cake on the steel platform, each partition includes multiple supporting seat positions, and each supporting seat position has a fixed position code in the computer system; in each wheel axle or wheel cake The opening space reserved on the upper part of the CNC machine tool is used to lift or place the wheel axle or wheel cake;

[0019] 3) Then install the hanging device on the upper part of the steel platform, and use the absolute position encoder to calculate the lifting and lowering, forward and backward positions of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com