Sealing structure for vacuum compaction road roller

A technology of sealing structure and road roller, which is applied in the direction of motor vehicles, crawler vehicles, transportation and packaging, etc., can solve problems such as difficult to guarantee sealing performance, rapid rubber plate wear, road surface damage, etc., achieve simple structure, reduce friction, The effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention are given below. It should be noted that the present invention is not limited to the following specific embodiments. All equivalent transformations made on the basis of the technical solutions of the present application fall within the protection scope of the present invention and comply with the foregoing technical solutions.

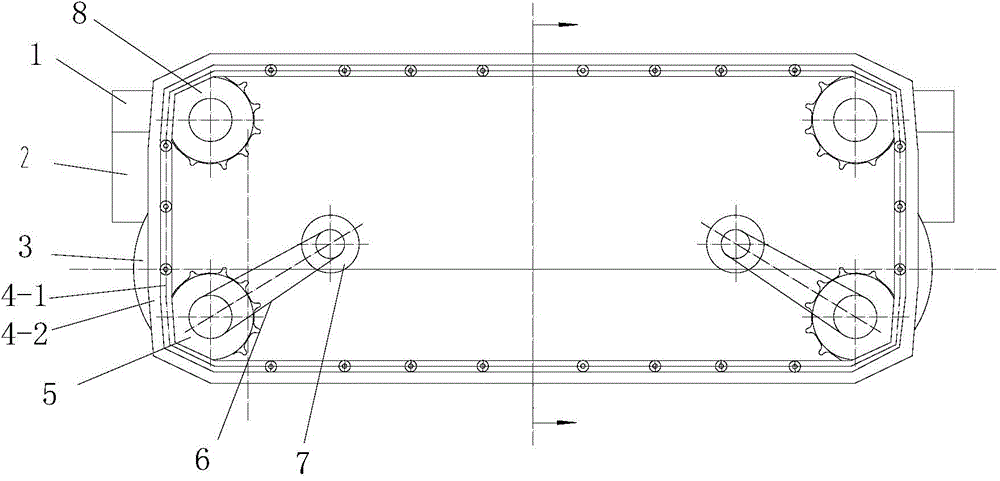

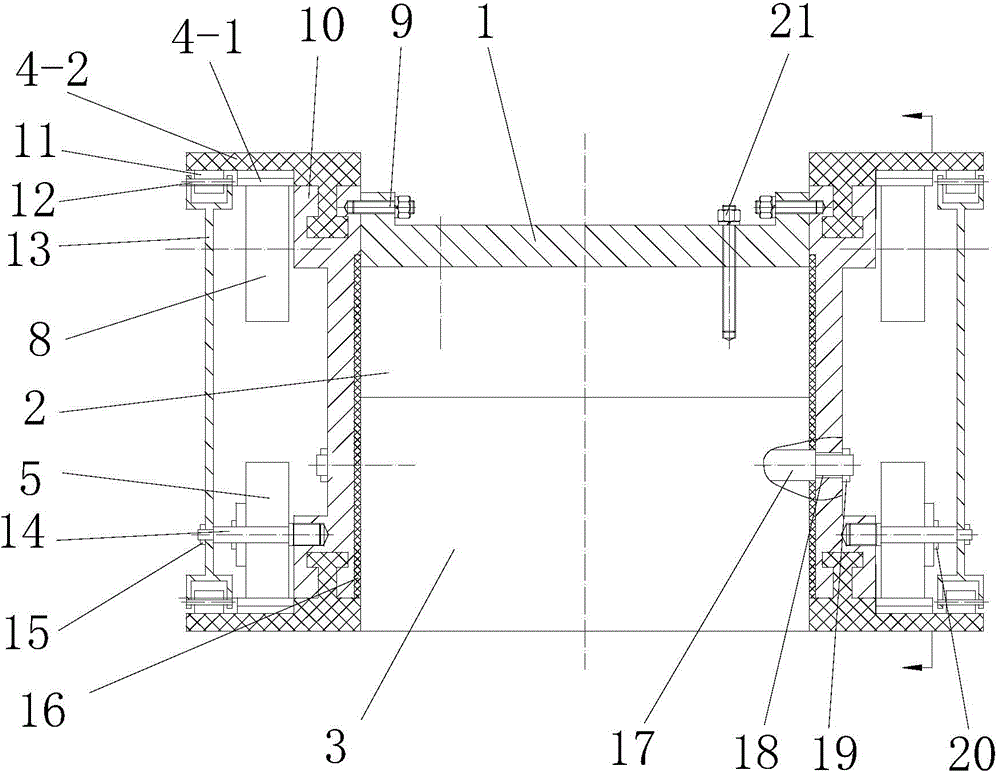

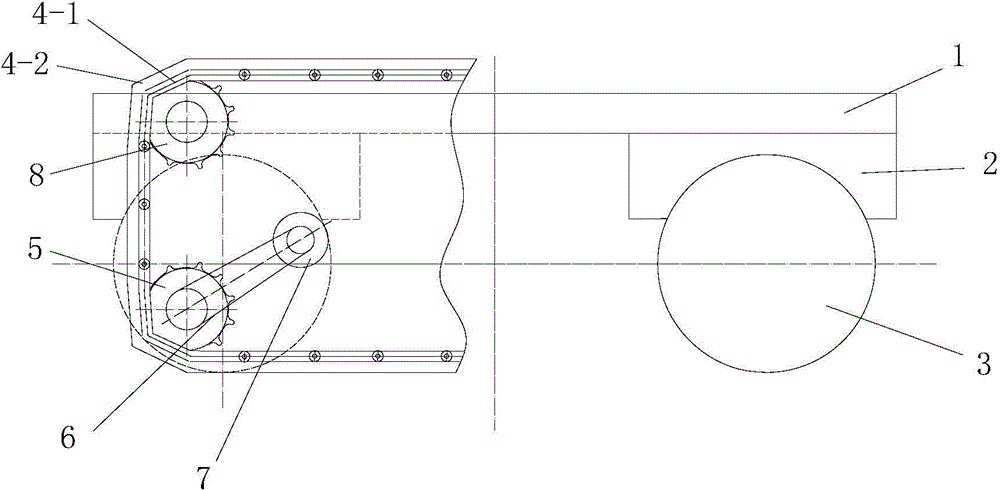

[0024] Such as Figure 1 to Figure 4 As shown, the sealing structure of a vacuum compaction roller of the present invention includes an upper steel plate 1 and two rubber plates 2 symmetrically installed on the left and right sides of the bottom surface of the upper steel plate 1. The bottom surface of each rubber plate 2 is provided with The arc-shaped grooves to which the steel wheels 3 fit, and the two steel wheels 3 are respectively arranged under the arc-shaped grooves on the bottom surface of the corresponding rubber plate 2; two side steel plates 10 with a thickness of 50 mm are symmetrically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com