Over-ground kiln type steam curing workshop with precast sleeper

A workshop and sleeper technology, applied in the field of sleeper prefabrication construction technology, can solve the problems of inability to meet the heating/cooling rate, construction safety cannot be guaranteed, and the heating/cooling rate is slow, so as to save construction costs, low requirements, and temperature control. standard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

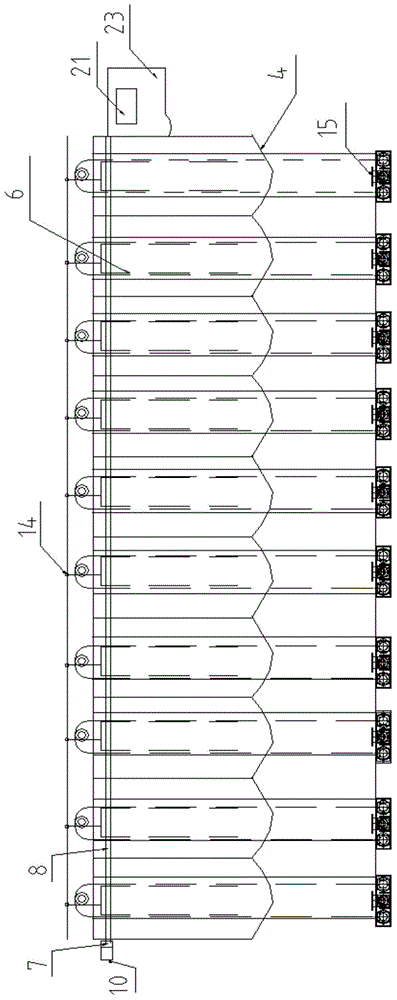

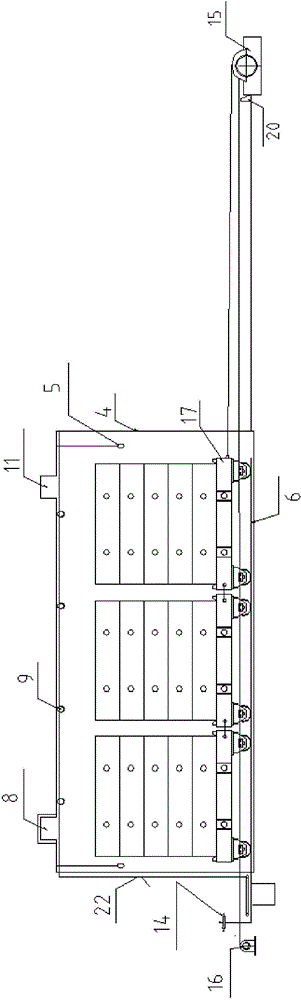

[0021] Such as Figure 1-Figure 2 An above-ground kiln-type steam curing workshop for sleeper prefabrication is shown, including a color steel plate house 1, a temperature control system, and a transportation system; the color steel plate house 1 includes a number of steam curing workshops 3; the temperature control system is set on the color steel plate Inside the room; the transportation system includes a number of winches 15, directional pulleys 16, mold transport vehicles 17, steel rails 18; the winches 15 are respectively located in the middle of the beginning of each steam curing workshop 3, and pass The steel wire rope 19 is connected to the directional pulley 16 installed on the opposite side; the steel track 18 is laid on the ground of the steam curing workshop 3 and extends to the corresponding hoist 15; the model transport trolley 17 is arranged on the steel track 18 and Connected with wire rope 19. Using this kind of transportation system, before the steam curing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com