Two-layer disk type tool changer device

A disc type, tool magazine technology, applied in the field of spare parts, to achieve the effect of good elasticity, not easy to damage, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

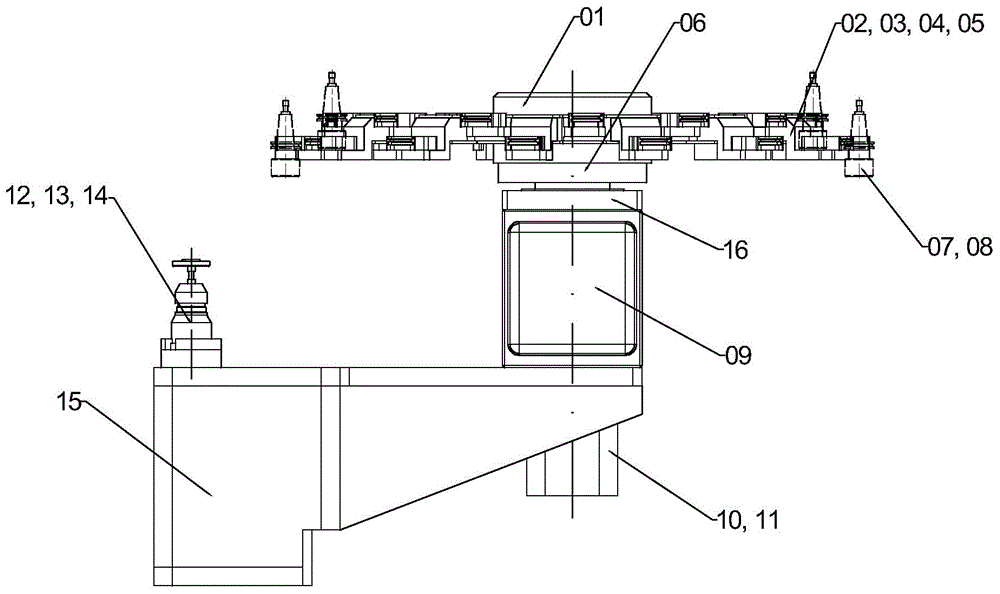

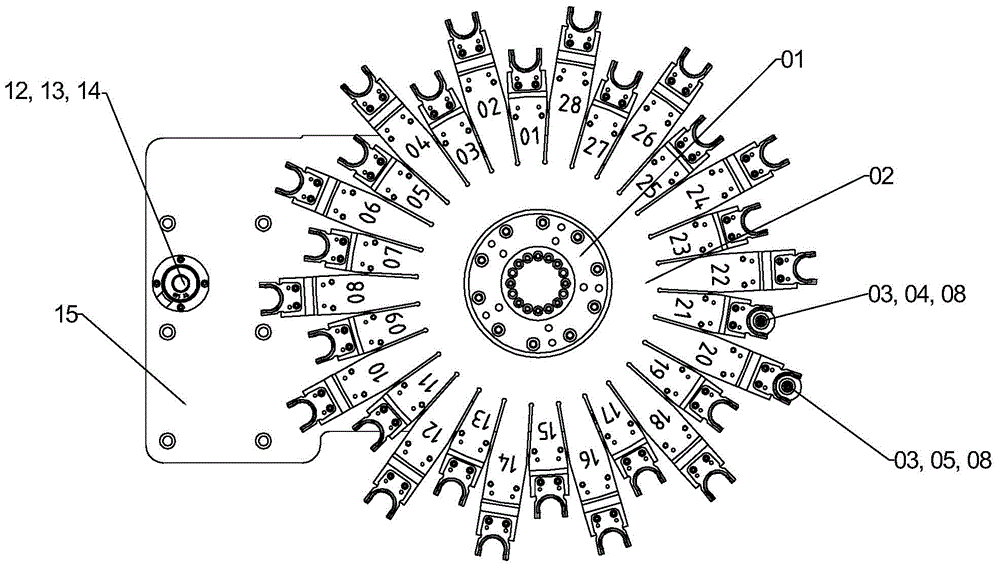

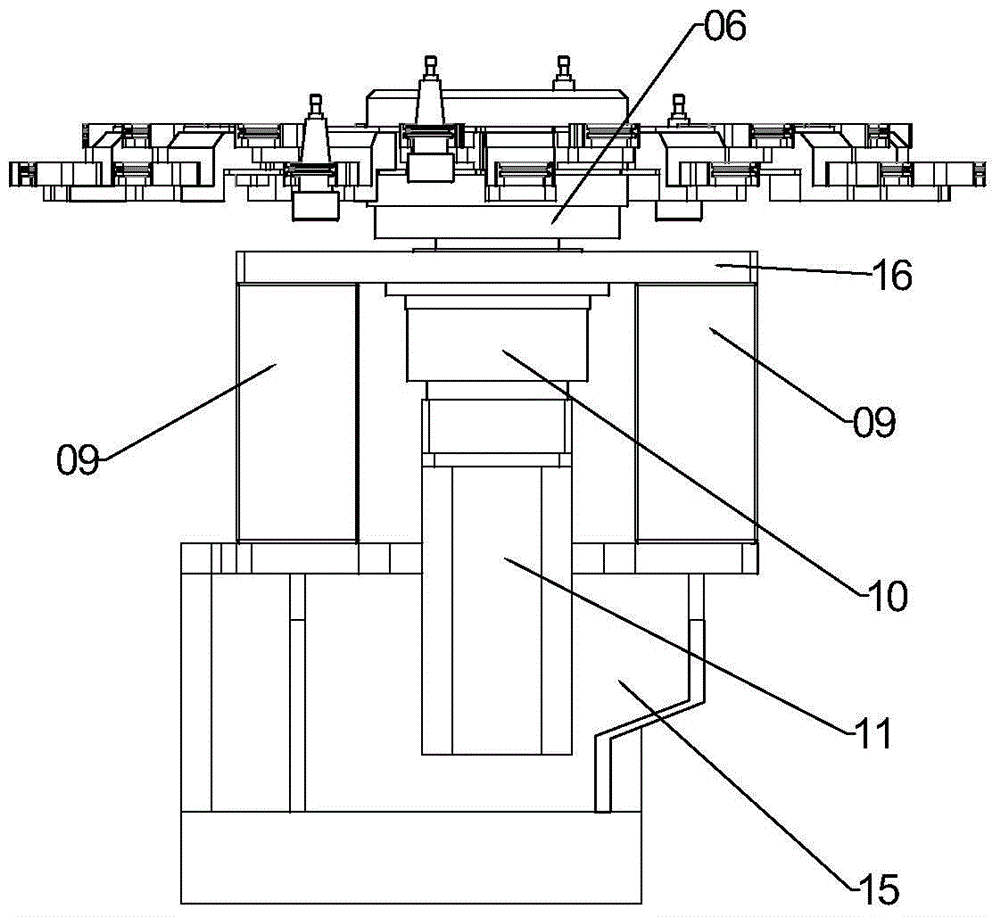

[0019] refer to Figure 1-Figure 5 , a double-layer disc-type tool magazine device matched to a CNC machine tool, including a tool magazine base 15, a tool magazine bracket 09, a tool pocket chuck 02, a knife tray base 06, and a knife pocket 07, and the knife pocket 07 is used for Set of various tools, the tool magazine base 15 is installed on the machine tool (not shown in the figure) through bolt connection, one end of the tool magazine base 15 (outside of the machine tool) is hollowed out into a U-shape, and a pair of tool magazine brackets 09 pass through Bolts are connected on both sides of the U shape, and a horizontal plate 16 is provided between the top of the tool magazine bracket 09; two tool holder chucks 02 are placed on the cutter head base 06, and the cutter head is used in the middle of the tool holder chuck 02 The spacer 03 is separated; the two-layer knife pocket chuck 02 clamps the upper knife pocket seat 04 and the lower knife pocket seat 05, and is fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com