Rear passenger car wall assembly welding clamp and technique using the same to weld rear wall assembly

A technology for assembly and passenger cars, which is applied in the field of assembly and welding fixtures for passenger car rear wall assembly, can solve the problems of large deformation of the rear wall skin and affect the appearance effect, etc., achieve the improvement of fineness and appearance effect, small deformation, and reduce welding effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

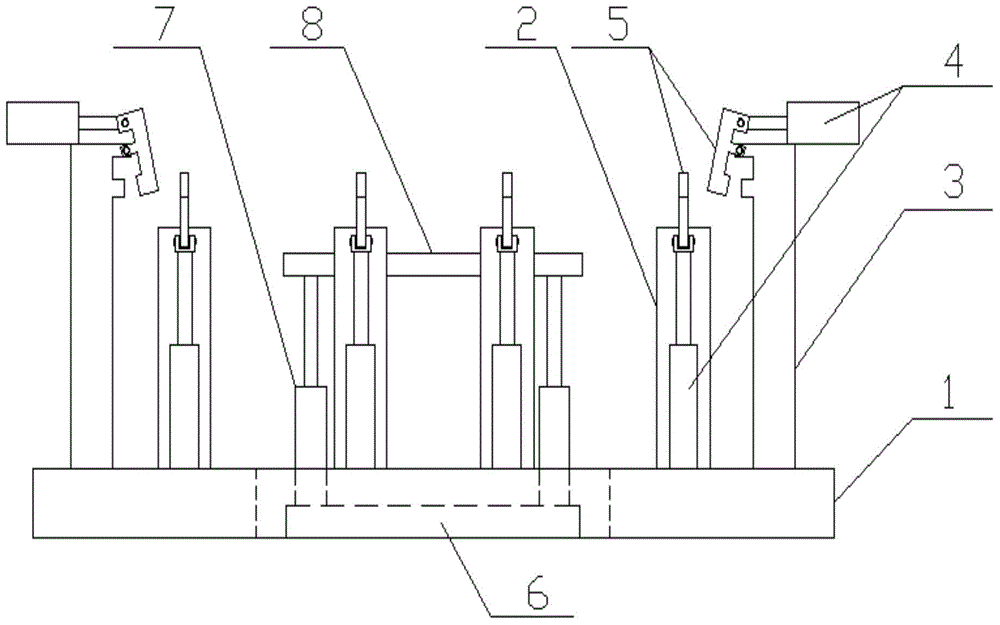

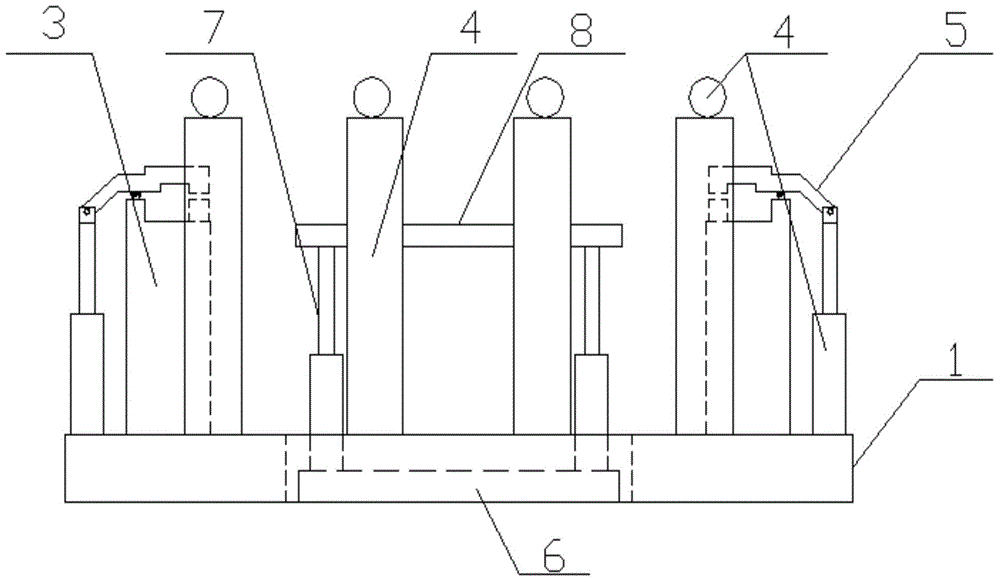

[0019] A fixture for assembly and welding of the passenger car rear wall assembly, comprising a base 1, a first pillar 2, a second pillar 3, a cylinder 4 and a clamping arm 5, the base 1 is a back-shaped structure with a rectangular through hole in the middle, the first There are a plurality of pillars 2 and second pillars 3 and they are respectively distributed on the front, rear and left and right sides of the upper end surface of the bottom plate 1. Each first pillar 2 and each second pillar 3 are correspondingly provided with a cylinder 4 and a clamp. Tighten the arm 5, the cylinder 4 corresponding to the first pillar 2 is vertically arranged outside the first pillar 2 and fixed on the upper end surface of the base 1, the clamping arms 5 at the front and rear ends of the base 1 are arranged transversely on the upper end of the first pillar 2, clamping The middle part of the arm 5 is hinged with the upper end of the first pillar 2, the outer end of the clamping arm 5 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com