Efficient air inlet apparatus used for gas-turbine air purification

An air purification and gas turbine technology, which is applied to gas turbine devices, jet propulsion devices, mechanical equipment, etc., can solve the problem of insufficient filter efficiency of the filter layer, and achieve the effect of improving the service life and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

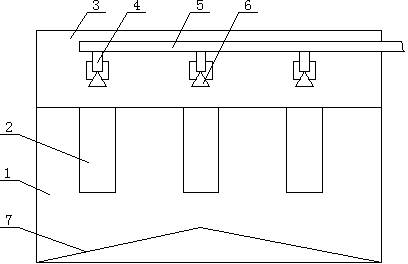

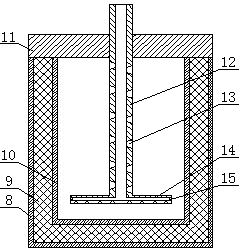

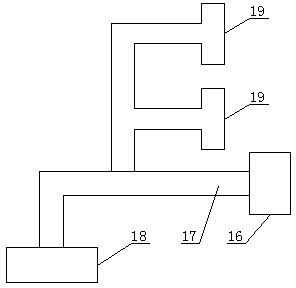

[0036] The high-efficiency air intake device for gas turbine air purification in this embodiment includes an air intake cavity, a filter cartridge, a blowback cavity and a blowback system, the blowback cavity is located at the upper part of the intake cavity; one end of the filter cartridge is located at In the air inlet cavity, the other end is located in the blowback cavity; the blowback system is arranged in the blowback cavity, and the blowback system includes a blowback pipe communicated with a compressed air source through a pipeline, and the air outlet end of the blowback pipe Equipped with a guide device, the center line of the guide device is on the same line as the center line of the blowback pipe and the center line of the filter cartridge; the filter cartridge includes a filter cartridge skeleton, and the filter cartridge skeleton is made of outer metal A mesh layer and an inner metal mesh layer, the outer metal mesh layer and the inner metal mesh layer form a cylin...

Embodiment 2

[0038] The high-efficiency air intake device for gas turbine air purification in this embodiment includes an air intake cavity, a filter cartridge, a blowback cavity and a blowback system, the blowback cavity is located at the upper part of the intake cavity; one end of the filter cartridge is located at In the air inlet cavity, the other end is located in the blowback cavity; the blowback system is arranged in the blowback cavity, and the blowback system includes a blowback pipe communicated with a compressed air source through a pipeline, and the air outlet end of the blowback pipe Equipped with a guide device, the center line of the guide device is on the same line as the center line of the blowback pipe and the center line of the filter cartridge; the filter cartridge includes a filter cartridge skeleton, and the filter cartridge skeleton is made of outer metal A mesh layer and an inner metal mesh layer, the outer metal mesh layer and the inner metal mesh layer form a cylin...

Embodiment 3

[0040] The high-efficiency air intake device for gas turbine air purification in this embodiment includes an air intake cavity, a filter cartridge, a blowback cavity and a blowback system, the blowback cavity is located at the upper part of the intake cavity; one end of the filter cartridge is located at In the air inlet cavity, the other end is located in the blowback cavity; the blowback system is arranged in the blowback cavity, and the blowback system includes a blowback pipe communicated with a compressed air source through a pipeline, and the air outlet end of the blowback pipe Equipped with a guide device, the center line of the guide device is on the same line as the center line of the blowback pipe and the center line of the filter cartridge; the filter cartridge includes a filter cartridge skeleton, and the filter cartridge skeleton is made of outer metal A mesh layer and an inner metal mesh layer, the outer metal mesh layer and the inner metal mesh layer form a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com